large cnc turning parts services

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 1200/Month |

|---|---|

| Transportation: | Ocean,Land,Air |

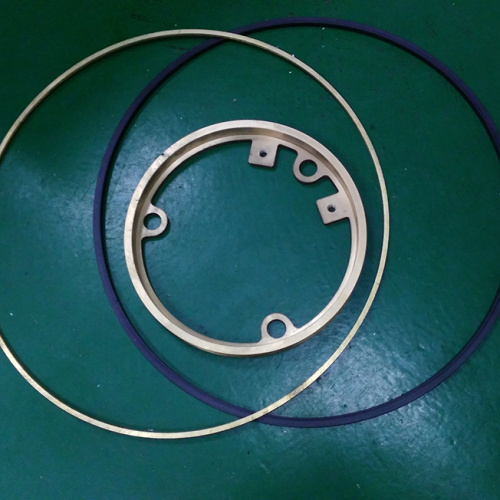

We offer large cnc turning parts services,The maximum diameter can be achieved ф860mm, length 1050mm. Concentricity of 0.02mm. perpendicular of 0.02mm..

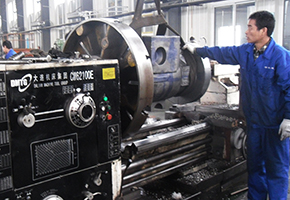

Our CNC turning has three configurations: Single Turret Single Spindle, Twin Turret Twin Spindle.As well as automatic feeding function.Using Esprit software CAM programming,The following cutting action can be performed:The following cutting action can be performed. There are six lathe. Machining tuinring size of the largest diameter can reach ф860mm.The cnc turnining and cnc milling machining materials are:Aluminum 6061,6063,6061-T6,7075,5052.2017.6082.

Alloy Steels,Carbon Steel,

Brass,Bronze ,

Stainless steel: 303,304, 316.

Plastic:Delrin,Neoflon®,Nylon,Phenolic Resin,PTFE,PC,ABS.

Secondary Services Offered:laser engraving LOGO.Anodizing,Plating Chrome,Nickel,RoHS Zin,Etc.Assembly Welding,Heat Treating,Powder Coating,Centerless Grinding.

Fast delivery is our advantage, CNC Turning parts, 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, the fastest sample to complete one day.The factory provides 2 ~ 3 sets of CNC Turning Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.

We attach importance to every customer, every CNC machining Turning drawing.For each drawing will organize a small seminar to arrange the production schedule, technical discussion, process scheduling, quality control point.We focus on the CNC Turning. accumulation of technology, product planning will be held regularly,Review the problems in the machining process, optimize the processing technology, improve the CNC machining quality and efficiency.

Our engineers focus on continuously improving CNC turning technology.A comprehensive understanding and master the CNC turning and CNC milling programming the basic process and key technologies.Proficiency in the use of CAD / UG / Master CAM software on the important processing procedures should be CNC Machining turning test.

The large cnc turning parts proceeds from the previous processing step to the next processing step.We will use the appropriate (or custom) PVC box for temporary storage products.Complete all CNC machining steps .Each product is packaged in EPE Poam and is available in custom cartons and crates to prevent the product from colliding during transport.Ensure that you can use the intact product.

CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Related Keywords