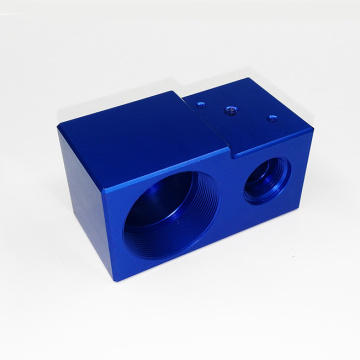

High Precision CNC Machining Turning Aluminum

-

$10.00≥10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 8000/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

High Precision CNC Machining Turning Parts for Industrial Automation Parts. All size Toleran: +/-0.02mm, some +/-0.01mm. We use CNC turning center to carry out high-precision machining of the products. The use of a reasonable tool on the workpiece roughing and finishing turning. We use the Tam Tam for the supply of accessories for testing.

Our CNC Turning Center is equipped with a multi-station turret or power turret. The machine has a wide range of machining performance, machinable linear cylinder, diagonal cylinder, arc and a variety of thread, groove, worm and other complex parts as well as six lathe. Machining size of the largest diameter can reach ф860mm, a single product the thinnest 0.23mm CNC turnining and CNC milling machining materials are: copper / bronze / H62, Titanium / TC4, aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082. Stainless steel: 1.4305,1.4301, SUS316, SUS303, SUS304. Steel: Q235,45#, A3, 718H, S136, SKD11 etc.. Plastic: POM, PA, ( PA66 ) PC, PMMA. Product surface treatment: anodize ( clear, black, blue, yellow, can also customize a variety of colors ), sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO.

ISO9001:2008 quality system runs through every department. We obtain the best quality of the products from the following points: The accuracy of the equipment, to meet the product quality of the CNC machining turning machining technology, the choice of tools and a reasonable auxiliary fixture. Training of workers. CNC lathe parts machining of each link detection.

We focus on short-term delivery, commitment to provide samples a week. For a simple CNC Turning parts, complete the sample in 3 days. The factory provides 2 ~ 3 sets of CNC Turning Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day. In order to meet these services, we also have a qualified supplier base, so that we can provide products from the surface to the parts LOGO mark the integrity of the quality of CNC turning services.

Related Keywords