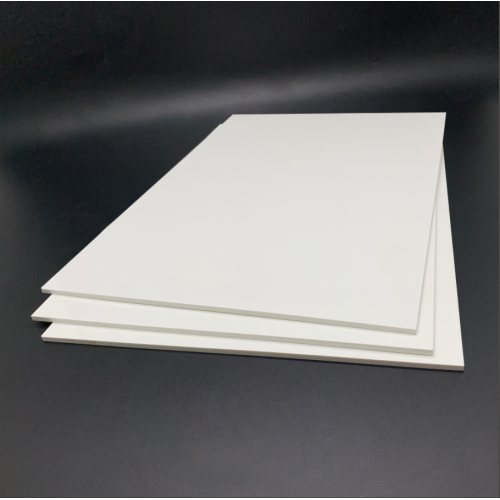

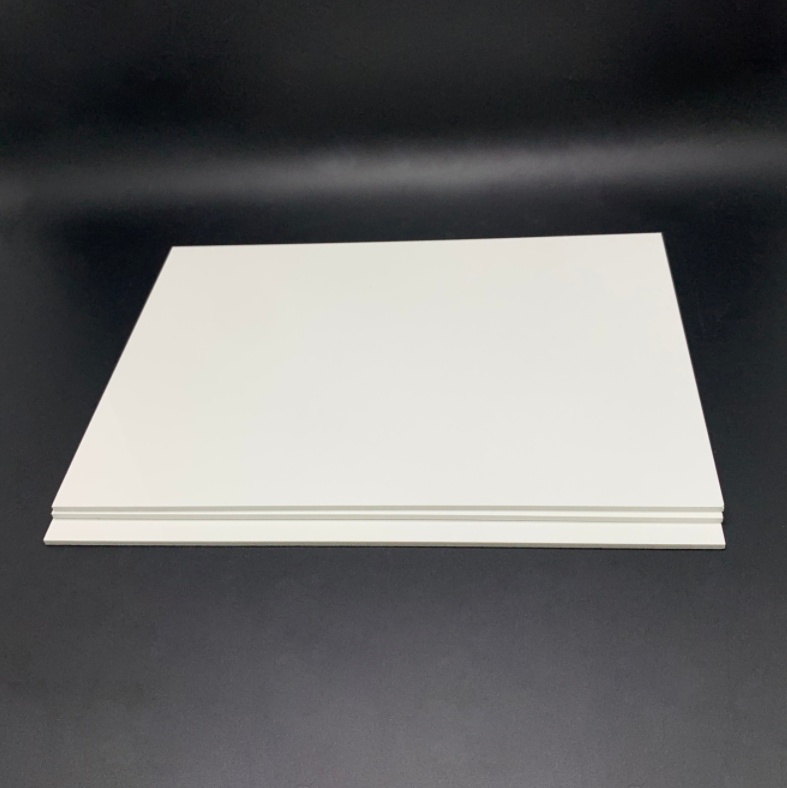

White SMC Sheet Material for Construction

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 30Tons/month |

| Supply Ability: | 30Tons/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,DDP,DDU,Express Delivery |

| Certificate: | RoHS |

| HS Code: | 3921909090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

SMC is a thermoset composite material composed of a resin matrix (25-35%, typically unsaturated polyester, vinyl ester, or epoxy), glass fibers (20-30% for reinforcement), fillers (40-60%, e.g., calcium carbonate, talc, or aluminum hydroxide), and additives (1-5%, including initiators, thickeners, and release agents). Optional components like carbon fibers, flame retardants, or low-shrink agents enhance specific properties.

The production process involves:

-

Mixing: Resin, fillers, and additives are blended into a homogeneous paste.

-

Thickening: Magnesium oxide is added to increase viscosity, forming a handleable sheet.

-

Fiber Incorporation: Chopped glass fibers (25-50 mm) are layered onto the resin paste.

-

Maturation: The sheet is stored to achieve optimal viscosity (24-72 hours).

-

Compression Molding: Pre-cut SMC sheets are placed in a heated mold (130-160°C, 5-20 MPa pressure) and cured for minutes to form the final product.

-

Post-Processing: Trimming and surface finishing are performed as needed.

SMC’s high-strength, lightweight, and corrosion-resistant properties make it ideal for automotive, electrical, and structural applications.

Characteristics and Applications of SMC (Sheet Molding Compound):

SMC is a high-performance thermoset composite renowned for its lightweight nature, high strength-to-weight ratio, and excellent dimensional stability. Key characteristics include:

-

Mechanical Strength: Reinforced with glass or carbon fibers, SMC offers exceptional tensile, flexural, and impact resistance comparable to metals like aluminum.

-

Corrosion Resistance: Resistant to chemicals, moisture, and UV exposure, making it ideal for harsh environments.

-

Thermal Stability: Retains properties at elevated temperatures (up to 180°C with specific resins).

-

Design Flexibility: Easily molded into complex geometries with tight tolerances, integrating ribs, bosses, and textures.

-

Electrical Insulation: Non-conductive properties suit electrical applications.

-

Flame Retardancy: Achievable via additives (e.g., aluminum hydroxide) for fire-sensitive uses.

-

Low Shrinkage: This minimizes post-molding distortion, ensuring precision.

Applications span diverse industries:

-

Automotive: Body panels, battery housings (EVs), bumpers, and under-hood components, reducing weight for fuel efficiency.

-

Electrical/Electronics: Circuit breaker enclosures, insulators, and switchgear due to dielectric strength and heat resistance.

-

Construction: Durable roofing, sanitary ware (bathtubs, sinks), and water tanks resistant to corrosion and wear.

-

Aerospace: Interior components and non-structural parts requiring lightweight durability.

-

Industrial: Pump housings, conveyor parts, and agricultural equipment benefiting from chemical resilience.

-

Renewable Energy: Wind turbine nacelles and solar panel supports.

SMC’s versatility, cost-effectiveness for mass production, and sustainability (recyclable options) position it as a critical material in modern engineering, displacing traditional metals and plastics.

Our company focuses on high-performance engineering plastics and insulation materials. Our main products include high-end engineering plastic sheets/rods such as polyoxymethylene (POM), ABS, nylon (PA), polycarbonate (PC), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), etc. We also provide special insulation materials such as bakelite (phenolic laminate) and epoxy glass fiber board. With excellent properties such as high temperature resistance, wear resistance and high strength, our products are widely used in new energy vehicles, smart electronics, industrial machinery, aerospace and other fields.

Related Keywords