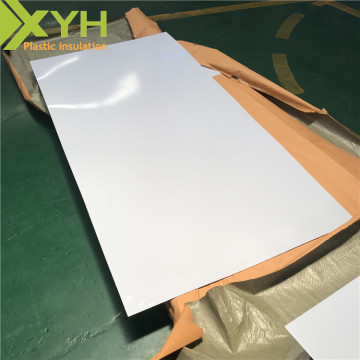

Versatile HIPS Sheet Ideal for Industrial Applications

$2.00 - $3.00/Kilogram

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shekou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | shenzhen |

|---|---|

| Productivity: | >10000kg |

| Supply Ability: | >10000kg |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES |

| Certificate: | Roth and SGS |

| HS Code: | 3920300000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shekou |

Product Description

Product Description

1. Introduction to HIPS Sheet

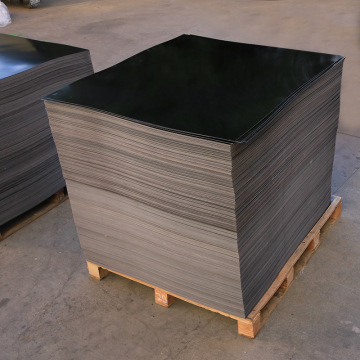

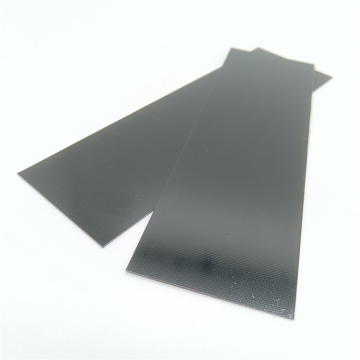

HIPS (High Impact Polystyrene), or high impact polystyrene, is a thermoplastic modified by introducing a rubber phase (such as polybutadiene) into ordinary polystyrene (GPPS). Its unique "island structure" (rubber particles dispersed in the PS matrix) gives it excellent impact resistance while retaining the easy processing and low-cost advantages of polystyrene. HIPS sheet is widely used in packaging, electronics, advertising and other fields, and is an ideal choice for balancing performance and economy.

2. Core characteristics of HIPS sheet

Impact resistance

Notched impact strength reaches 50–150 J/m (ASTM D256), which is 5 to 10 times that of ordinary PS, and can withstand drops and collisions.

Easy processing

The heat deformation temperature (HDT) is 70–90°C (0.45MPa), which is suitable for thermoforming, blister molding, injection molding and other processes.

Surface quality

High finish, can be directly printed, sprayed or vacuum coated without additional processing.

Lightweight

Density 1.04–1.06 g/cm³, about 8% lighter than ABS, suitable for scenarios with strict weight reduction requirements.

Food safety

Compliant with FDA and EU 10/2011 standards, widely used in food containers and tableware.

Related Keywords

Related Keywords