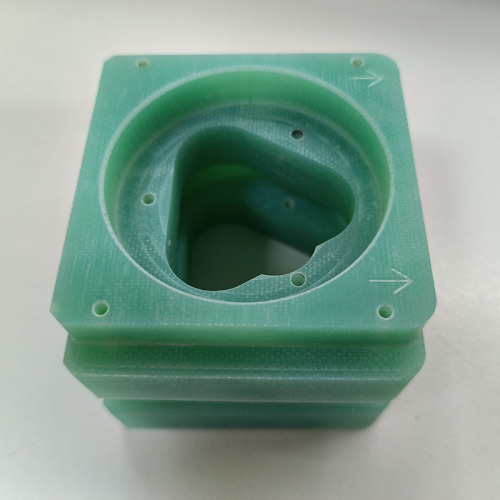

Fr4 Processing Parts For Electronic Switch Mold

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

Ingredients

Base material: Glass fiber cloth (electronic grade) is used as a reinforcing material to provide mechanical strength and structural stability.

Resin system: A combination of epoxy resin and hardener is used. Some formulas contain brominated epoxy resin to achieve flame retardant properties.

Additional components: Some products add fillers (such as inorganic substances) to optimize dielectric properties or thermal stability

Performance characteristics

Mechanical properties:

High rigidity, tensile strength (up to 150MPa or more at room temperature) and compressive strength, suitable for the load-bearing requirements of precision molds.

Excellent low-temperature toughness (mechanical stability at -40°C), high temperature tolerance up to 130°C.

Electrical properties:

Stable dielectric constant (≤5.5 @1MHz), low dielectric loss (≤0.04), dry/wet insulation resistance are higher than industry standards.

Flame retardancy: UL94V0 certified, self-extinguishing time after burning ≤10 seconds, meeting electronic equipment safety regulations.

Processing adaptability:

Supports precision processing such as CNC and laser cutting, edge flatness error ≤0.05mm.

Low water absorption (≤19mg under D-24/23 standard), dimensional stability is better than ordinary engineering plastics

Core selling point of the product

Multi-scenario applicability:

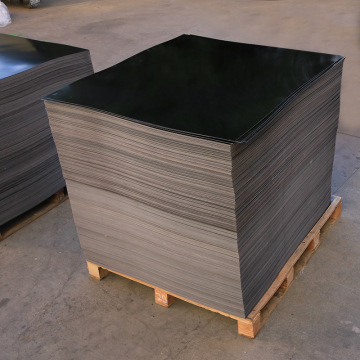

Optional colors (yellow/white/black/aqua), smooth surface without pits, meeting the needs of appearance customization.

High cost performance:

The cost of raw materials is 30%-50% lower than that of metal substrates, and the processing loss rate is ≤3%.

Environmental compliance:

Compliant with the RoHS directive, halogen-free formula reduces the risk of environmental pollution.

Application areas

Electronic switch molds:

As insulating support bars and contact fixing plates, they can solve the problem of high-voltage arc breakdown.

Precision structural parts:

Used for wafer grinding gears and test fixtures, replacing traditional metal parts to reduce weight.

Extended scenarios:

High-frequency communication equipment (such as 5G base station RF module insulation pads).

New energy vehicle electronic control systems (battery pack insulation isolation plates, charging pile components)

| Property | Bakelite sheet | FR4 sheet |

| Base Material | Phenolic resin + wood pulp/cotton fabric | Epoxy resin + glass fiber |

| Cost | Lower | Higher |

| Temperature Resistance | 100-130°C | 130-180°C (higher for epoxy board) |

| Electrical Performance | Medium/Low Voltage Insulation | High-Frequency/High Voltage Insulation (superior) |

| Typical Applications | Mechanical parts, medium/low voltage electrical devices | PCB substrates, high-end insulating components |

| Comparison Table: 3240 Epoxy Glass Sheet vs. FR4 Sheet | ||

| Characteristics | 3240 Epoxy Glass Sheet | FR4 Sheet |

| Main Applications | Structural insulation parts, mechanical support | Printed circuit board (PCB) substrate |

| Key Processing Techniques | Mechanical processing (cutting, drilling) | PCB processes (etching, copper plating, etc.) |

| Key Performance Focus | Mechanical strength, insulation | High-frequency signal transmission, dielectric stability |

| Typical Thickness | 0.5mm–50mm (thicker) | 0.2mm–3.2mm (thinner) |

Related Keywords

Related Keywords