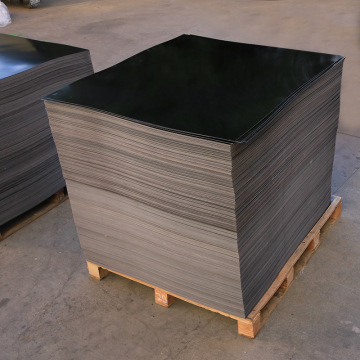

Electrical Insulation Fr4 Sheet Price

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

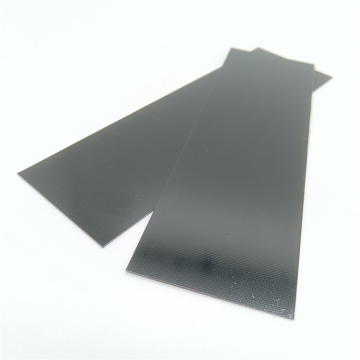

Product Composition:Composite materials laminated by epoxy resin and glass fiber cloth are widely used in electronics, electrical, communications and other fields due to their excellent electrical properties, mechanical strength and heat resistance. The "FR" in FR4 stands for "Flame Retardant", indicating that it has good flame retardant properties.

Performance Characteristics

Electrical insulation: high insulation resistance, low dielectric constant, suitable for high-frequency circuits.

Mechanical strength: high bending strength and impact resistance.

Heat resistance: can remain stable at higher temperatures, usually 130°C to 140°C.

Flame retardancy: meets UL94 V-0 flame retardant standards and has good fire resistance.

Chemical resistance: good resistance to most chemicals.

Dimensional stability: can remain dimensional stable under changes in temperature and humidity.

High performance: excellent electrical and mechanical properties, suitable for demanding applications.

Flame retardancy: meets strict flame retardant standards and is highly safe.

Versatility: suitable for a variety of electronic and electrical applications.

Processability: easy to cut, drill and surface treat.

Environmental protection: some products comply with environmental protection standards such as RoHS.

Application Fields

PCB manufacturing: FR4 is the main material for manufacturing printed circuit boards (PCBs) and is widely used in electronic devices.

Electrical insulation: used for insulating components of electrical equipment such as transformers, relays, switches, etc.

Communication equipment: used for high-frequency communication equipment such as antennas and filters.

Industrial control: used for circuit boards and insulating components in industrial control systems.

Automotive electronics: used for automotive electronic control units (ECUs) and sensors, etc.

Aerospace: used for high-performance circuit boards in aerospace electronic equipment.

| Comparison Table: 3240 Epoxy Sheet vs. FR4 Sheet | ||

| Characteristics | 3240 Epoxy Glass Sheet

|

FR4 Sheet |

| Main Applications | Structural insulation parts, mechanical support | Printed circuit board (PCB) substrate |

| Key Processing Techniques | Mechanical processing (cutting, drilling) | PCB processes (etching, copper plating, etc.) |

| Key Performance Focus | Mechanical strength, insulation | High-frequency signal transmission, dielectric stability |

| Typical Thickness | 0.5mm–50mm (thicker) | 0.2mm–3.2mm (thinner) |

| Property | Bakelite sheet | FR4 sheet |

| Base Material | Phenolic resin + wood pulp/cotton fabric | Epoxy resin + glass fiber |

| Cost | Lower | Higher |

| Temperature Resistance | 100-130°C | 130-180°C (higher for epoxy board) |

| Electrical Performance | Medium/Low Voltage Insulation | High-Frequency/High Voltage Insulation (superior) |

| Typical Applications | Mechanical parts, medium/low voltage electrical devices | PCB substrates, high-end insulating components |

Related Keywords

Related Keywords