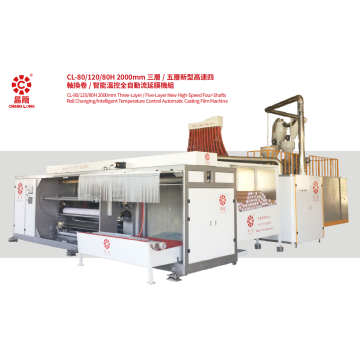

1500mm Co-Extruded Automatic Protective Film Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen, China |

|---|---|

| Productivity: | 280kg/ h |

| Supply Ability: | 20-30 sets/ month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE, ISO9001:2008 |

| Transportation: | Ocean |

Machine specification

1、Thickness adjustment scope:10µm-50µm;

2、Equality percent of thickness:≤±5%;

3、Width of effective film:1 500mm(max) or 3*500mm ;

4、Structure of film layers:A/B/C or A/C/B/C/A Co-extruded;

5、The fit material:LLDPE,LDPE, MLLDPE;

6、Extrusion capacity(max):250kg/h.

7、Installation dimension(L*W*H): 9.6*4.5*4.5m;

8、Weight: 14T

Characteristic

This unit mainly suitable for the production of cast film, protective film , forage film and wrapping film of CPE、CPP、PP、PE、CEVA etc, It can be installed with corona device for printing.

ADVANTAGE :

Film side whipstitch device (make both sides film more stable)

★ Edge material Using online independent traction devices

★ Winding roll: Use the high quality steel and special processing gush arenaceous (make films produced when coiling bubble natural ruled out)

★ Automatic material cutting and coil changing device (patented technology), safe and reliable.

★ The cooling roller adopts the double-layer circulation cooling system with

large diameter, many inner helical ways make the temperature of the roller equally,highly improved the cooling effect and cooling speed.

★ Air Shaft automatic upper and return: The device is designed meticulously by our company, to apply for a patent and the patent department, make the heavy air shaft automatic upper and return, simple, easy to operate,save artificially, improve work efficiency.

1.Built-In Spiral Flow Path Ensure Uniform Temperature Of The Roller Surface.

2.The winder adopts the middle aisle platform, which is convenient for on-line detection of the thickness of the film and adjustment and replacement of the cutter.It can realize double-sided non-stop change of the cutter, which is safe and easy to operate.

3.The winder can use the online flying knife deviceto solve the problem of automatic material cutting of special films of different thicknesses.

Certificate

Certificate of quality management system

Product Package

Seller provides the simple pearl wool with film package & wooden motherboard.

Client Cooperation

The sales network covers more than 80 countries and regions around the world.

Workshop

1.High Precision CNC Machine Tools

2.CNC Machining Center

3.High Precision Machining Machine

After-Sales Service

Warranty period and testing procedure:

The seller freely provides the fittings during the warranty for 12 months with the maintenance forever

when the equipment is tested OK. (Human factor and force irresistant factor exception.)

The seller provides the debugging and setting, Seller free to provide about one week training

but provide the round-trip ticket , other traveling costs should be paid by buyer.

Our professional engineering team is constitutive of excellent technical staff.

We can provide perfect after-sales service in time, give a good technical training to ensure the product in best state perennially.

Related Keywords