Meltblown Nonwoven Fabric Machine For Face Mask

- Payment Type:

- L/C, T/T, D/P

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45-50 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 850-1000kg/24h |

| Supply Ability: | 20-30sets/m |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean |

| Port: | Shenzhen |

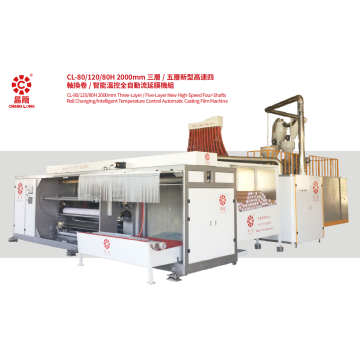

Technical Information For Meltblown Nonwoven Fabric Machine For Face Mask

Material: PP chips MFI 1200-1800

Fabric usage: medical mask, garment warm-keeping material, car cover, oil aboebent felt, baby diaper, gas filter, disposable products, etc.

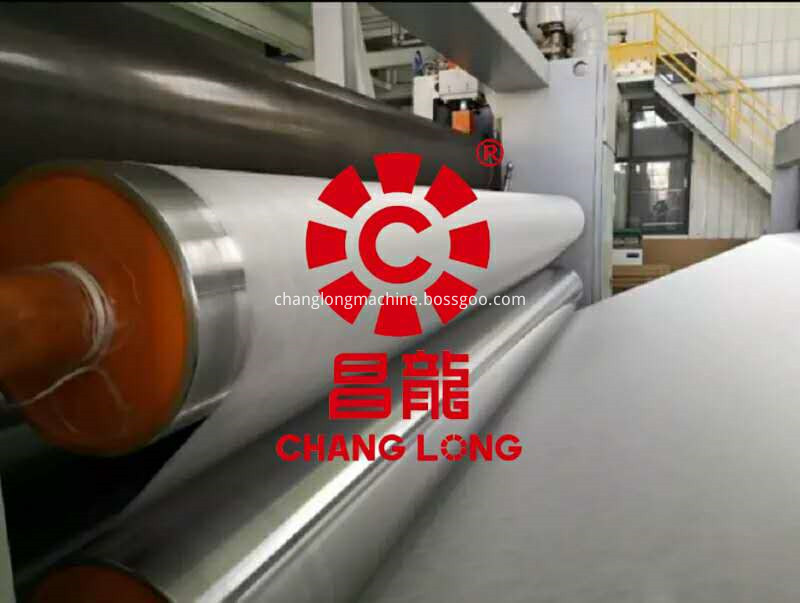

The line is application for PP chips as raw materials input, undergoes the process of extrusion, spinning, trickle quenching, web forming, winding and cutting as per requirements and then packed for storage and delivery.

Technical Data For Meltblown Nonwoven Fabric Machine For Face Mask

- Raw material: PP

-Technics :meltblow

-Fabric GSM: 10g/sm-200g/sm

-Color of Fabric can make : beyond 30 kinds

-Embossing : Diamend

-Machine Power :300KW

-Fabric width can make : From 600m to 1.6m

Application Fields of Meltblown Nonwoven Fabric Machine For Face Mask

Fabric usage: medical mask, garment warm-keeping material, car cover,

oil aboebent felt, baby diaper, gas filter, disposable products, etc.

Working Process of Meltblown Nonwoven Fabric Machine For Face Mask

Flow chart

Raw Material(Edge Material Recycling)- Melt Extrusion- Filter Metering -Meltblow device - Web Forming Machine - Winding and Slitting Machine -Finished Products

WorkShop Meltblown Nonwoven Fabric Machine For Face Mask

Exhibition :

Packing :

Aftersales Service :

Our professional engineering team is constitutive of excellent technical staff.

We can provide perfect after-sales service in time, give a good technical training to ensure the product in best state perennially.

Related Keywords