Jumbo Rolls Stretch Film Production Line

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- SHEKOU, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 560kg/h |

| Supply Ability: | 1-50sets/y |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO90001:2008 |

| HS Code: | 8477209000 |

| Transportation: | Ocean |

| Port: | SHEKOU,Chiwan |

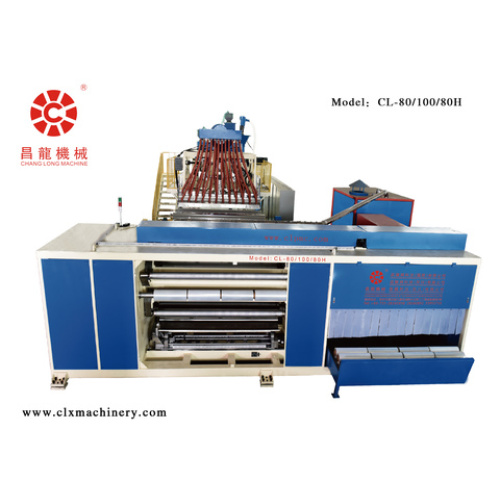

Jumbo Rolls Stretch Film Production Line Model CL-80/120/80H

Unleash Your Production Potential with Our High-Speed Jumbo Roll Stretch Film Line

Looking to significantly enhance your stretch film production capabilities? Our Jumbo Roll Stretch Film Production Line is expertly designed to deliver performance and efficiency. Featuring advanced High Speed Stretch Film Machine technology, this line is ideal for creating large, robust rolls of stretch film suitable for even the most demanding applications.

What Makes Our Line Stand Out?

Speed and Output: Harness the power of High Speed Stretch Film Unit capabilities with our line's rapid extrusion and winding features. This translates to substantially increased output and enhanced productivity, allowing your business to meet higher demand efficiently.

Jumbo Roll Expertise: As specialists in producing large-diameter rolls, our line minimizes the need for frequent roll changes, thus maximizing operational uptime.

Versatility and Customizability: Tailor our lines to precise production requirements, from the type of resin used to the dimensions of the rolls, ensuring you deliver exactly what your clients need.

Advanced Technology

Our lines incorporate technology:

Precise Thickness Control: Maintain consistent film thickness throughout the production process, reducing material waste and ensuring uniform product quality.

High-Efficiency Cooling Systems: Our cooling systems quickly solidify the extruded film, enhancing its strength and clarity.

Automated Winding Systems: Integrated into our Automatic High Speed Stretch Film Machinery, these systems allow for efficient winding of large rolls with minimal manual handling.

Applications

The versatility of our Jumbo Roll Stretch Film Production Lines means they are perfect for a variety of industries:

Logistics and Warehousing: Secure heavy pallets during transport and storage.

Manufacturing: Protect finished goods during the shipping process.

Distribution Centers: Optimize palletizing and unitizing operations, making them faster and more efficient.

Why Choose Us?

Quality Craftsmanship: Our machines are built with high-quality components, adhering to stringent quality control standards to ensure durability and reliability.

Exceptional Customer Support: Benefit from our dedicated team of engineers and technicians who offer comprehensive support from installation to training and beyond.

Focus on Innovation: We continuously invest in research and development to incorporate the latest advancements in stretch film production.

Ready to Boost Your Production?

Elevate your manufacturing capabilities with a High Speed Stretch Film Machine that meets your specific needs. Contact us today for a personalized consultation, and let our experts help you configure the perfect Jumbo Roll Stretch Film Production Line. Enhance your production capabilities, optimize your operations and step ahead of the competition with our tailored solutions.

Jumbo Rolls Stretch Film Production Line

Features:

1.Gear box is driven by motor through coupling.

2.High quality ceramic heater which keep warm and keep the heater in a suitable temperature to guarantee the plastizing,when the temperature becomes higher,the fans will start to work ,to make the screw be cool.

3.Double high precision stainless steel vacuum box device.

4.Big diameter cooling roller device, with special design: water one way inside and one way out, spiral channel which make the film cooling fast with good transparency.

5.Discharging the finished products and change paper core at the same time,which saves about 25-30s and realized the products 2-3kg small film can be made on line in high speed.

6.Automatic edge material recycling system with on-line vacuum makes the process of rewinding more smooth, increase the fracture resistance,and decrease the limitation by liner speed.

Related Keywords