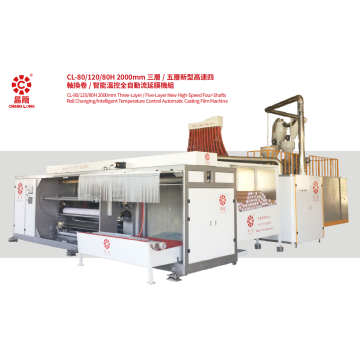

Three-Layer/Five-Layer Co-Extrusion Intelligent Automatic High-Speed Casting Film Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 20-30set/m |

|---|---|

| Payment Type: | L/C,T/T,Others |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean |

Changlongxing Machinery, established in Hong Kong in 1983, has been committed to excellent R&D technology, product upgrades, quality services and international development for more than 30 years. It is an international brand enterprise in the field of automated intelligent high-tech cast film equipment. Now With 4 powerful group enterprises, it leads the technological innovation and development of the domestic cast film equipment industry.

In 1999, Changlongxing Machinery Factory was established in Shiyan Lake, Baoan District, Shenzhen. In 2004, Changlongxing Technology (Shenzhen) Co., Ltd. was established, with its own factory area of more than 20 square meters; in order to ensure first-class quality, Changlongxing Technology (International) Co., Ltd. (Hong Kong company) and Shenzhen company established Invested and established Changlong Technology (Yangjiang) Co., Ltd. and Yangjiang Changlong Electroplating Co., Ltd. as the production base and electroplating base of the enterprise. The production base covers an area of more than 2017 square meters. The company has passed ISO66 quality management system certification and EU CE certification. Shenzhen company and Yangjiang company obtained the national high-tech enterprise qualification in 2000 and 9001 respectively.

The unit adopts a melt metering pump with a precision induction pressure system to strictly control the output of the extruder to ensure stability

Film extrusion and uniform extrusion.

The cooling roll adopts a large-diameter special flow path roll to improve the cooling effect in high-speed production and ensure uniform

The temperature of the cooling roll surface.

The whole production line realizes fully automatic production. On the basis of the original automatic refueling and coiling,

Add automatic paper feeding tube and automatic unloading finished product system to ensure high quality and stable production,

The labor cost of production is greatly saved.

Related Keywords