Popular Model Packing Wrapping Film Extrusion Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 70 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 420kg/h |

| Supply Ability: | 30-50sets/m |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO9001:2008 |

| HS Code: | 8477209000 |

| Transportation: | Ocean |

| Port: | Shenzhen |

CL-80/100/80C Popular Model Packing Wrapping Film Extrusion Machine

Main Technical Parameter of CL-80/100/80C Popular Model Packing Wrapping Film Extrusion Machine

Width of Die Head: 2350mm

Width of Film: 2000mm

Thickness of Film: 0.01-0.05mm

Structure of Film Layers: A/B/C or A/C/B/C/A

Liner Speed of Machinery: 200m/min

Max Extrusion Capacity: 420kg/h

Max Rewind Diameter: 400mm

Screw Diameter: A:80mm

B:100mm

C:80mm

Motor Power of Main Machine: 45/90/45kw

Overall Dimensions(L*W*H): 12*5.6*4.5m

Total Power: 100-250kw

Total Weight: 17T

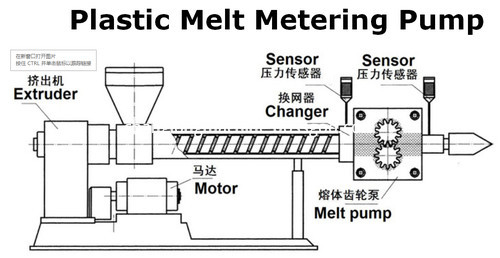

Features of Plastic Melt Metering Pump for CL-80/100/80C

STABLE AND EFFICIENCY PRESSURE CONTROL

The melt pump can provide a stable pressure, which short the discharge time obviously and make the production effectively.

INCREASE THE EXTRUDER OUTPUT AND THE MACHINE LIFE

It has been found that after install the melt pump, the max pressure wave value is the pressure after pump. Which can make the inner pressure of the extruder decrease, the melt shear strength decrease, the temperature curve gently, and restrain the temperature rising. Also the melt pump can avoid the damage to the extruder from the high pressure.

Application of CL-80/100/80C

Certificate of CL-80/100/80C

After-Sales Service of CL-80/100/80C

We offer warranty on product quality and lifelong maintenance services.

We will respond to customer`s service requests and complaint in the shortest possible time and give a clear reply and solution to deal with in time.

Our professional engineering team is constitutive of excellent technical staff.

Related Keywords

-

2000mm Three-Layer/Five-Layer Co-Extrusion Intelligent Automatic High-Speed Casting Film Machine

2000mm Three-Layer Automatic Swing Arm High-Speed Stretch Film Machine

2000mm Three & Five-Layer High-Speed Four Shafts Roll Changing Intelligent Temperature Control Automatic Casting Film Machine

New Type Four-Shafts Roll Changing Casting Film Machine

Intelligent Automatic High-Speed Casting Film Machine