2.0M Advanced Stretch Film Machinery

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 70 Days

- Transportation:

- Ocean

- Port:

- SHEKOU, CHIWAN, YANTIAN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 460kg/h |

| Supply Ability: | 20-50 sets/year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO9001:2008 |

| HS Code: | 8477209000 |

| Transportation: | Ocean |

| Port: | SHEKOU,CHIWAN,YANTIAN |

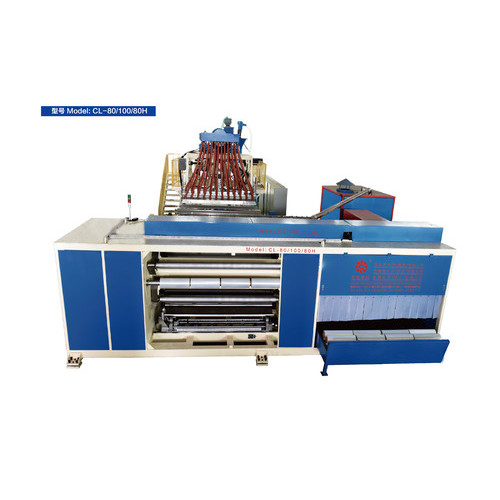

Breif Picture of CL-80/120/80H 2.0M Advanced Stretch Film Machinery

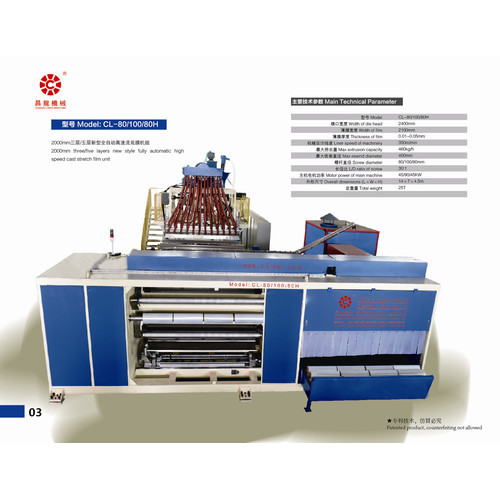

Breif Parameter of CL-80/120/80H 2.0M Advanced Stretch Film Machinery

1.Structure of Film Layers of CL-80/120/80H Advanced Plastic Stretch Film Machinery:A/B/C or A/C/B/C/A Co-extruded;

2.The Fit Material of CL-80/120/80H Advanced Stretch Film Machinery:LLDPE,LDPE, MLLDPE;

3.Extrusion Capacity(max) of CL-80/120/80H Advanced Plastic Stretch Film Machinery:460kg/h;

4.Thickness Adjustment Scope of CL-80/120/80H Advanced Stretch Film Machinery:10µm-50µm;

5.Equality Percent of Thickness of CL-80/120/80H Advanced Plastic Stretch Film Machinery:≤±5%;

6.Width of Effective Film of CL-80/120/80H Advanced Plastic Wrapping Film Machinery:2000mm(max) or 4*500mm;

7.Line Speed Max of CL-80/120/80H Advanced Plastic Wrapping Film Machinery: 350m/min

8.Installation Dimension(L*W*H) of CL-80/120/80H Advanced Plastic Wrapping Film Machinery: 14*6.5*4.5m

9.Weight of CL-80/120/80H Advanced Stretch Film Machinery: 25T

10.T-die Brand of Advanced Plastic Wrapping Film Machine:ChangLong Machinery

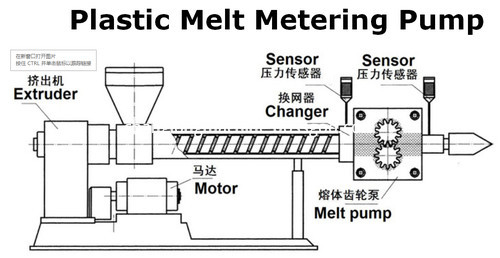

Advantages of Plastic Melt Pump for High Speed CL-80/120/80H 2.0M Advanced Stretch Film Machinery

Advantages:

FASTEN AND STABLE SUPPLY FLOW OF RAW MATERIAL

Eliminate the extruder`s pulsation wave.

Improve the product quality.

Decrease the defective rate and waste, which can save 2% raw material and 25% of the unit power consumption.

ENSURE STABLE AND EFFICIENTPRESSURE CONTROL

The melt pump can provide a stable pressure, which short the discharge time obviously and make the production effectively.

INCREASE THE EXTRUDER OUTPUT AND THE MACHINE LIFE

It has been found that after installing the melt pump,the inner pressure of the extruder decreases a lot while the melt shear strength decrease.

Also the melt pump can avoid the damage to the extruder from the high pressure.

Warmly Welcome To Visit Our Factory

Related Keywords