Semi-Automatic Flat Bottle Stikers Labeling Machine

-

RMB80001-0 Pack/Packs

-

RMB9000≥1 Pack/Packs

- Payment Type:

- T/T

- Min. Order:

- 1 Pack/Packs

- Min. Order:

- 1 Pack/Packs

- Delivery Time:

- 10 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 100 |

| Payment Type: | T/T |

| Certificate: | ce |

| Transportation: | Ocean |

Applicable labeling products

Applicable label

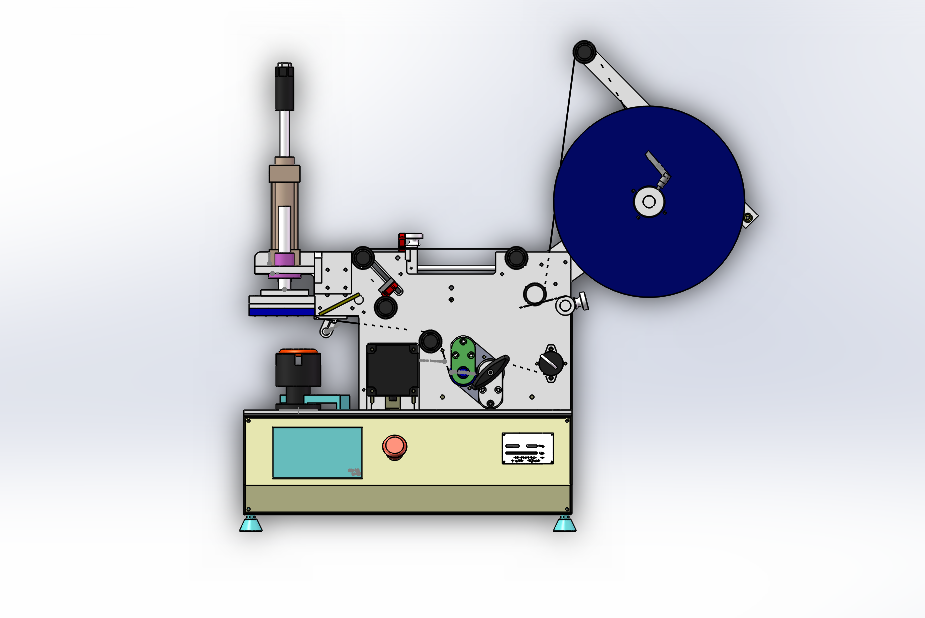

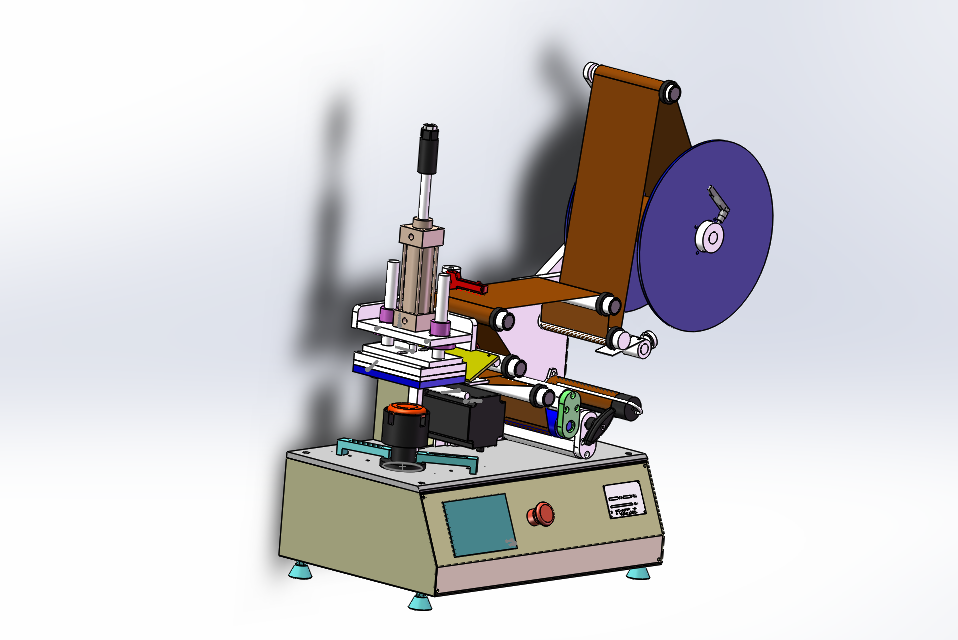

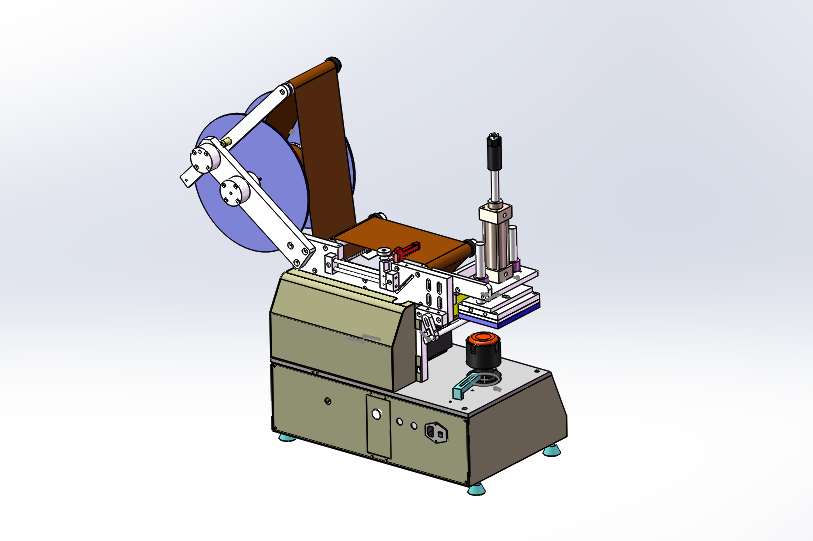

Machine picture

I, The basic purpose

Application of suction stickers labeling method to achieve the various parts of the plane on the labeling, such as cosmetics flat bottles, boxes, plastic cover labeling and so on.

Change overlying scale mechanism, suitable for uneven surface labeling, such as concave flat, circular surface labeling and so on.

Changing fixture, suitable for a variety of irregular work piece labeling.

Optional ribbon printer or inkjet printer, print production date on the label and batch number, to achieve a code – Labeling Integration.

II,Scope

Applicable Label: self-adhesive labels, self-adhesive film, electronic supervision code, bar code, etc.;

Applicable products: requirements in flat or curved, circular surface, concave, convex, or other surface attached label products;

Industry: Widely used in cosmetics, food, toys, cosmetics, electronics, pharmaceutical and other industries;

Application: Shampoo flat bottle labeling, packaging labeling, bottle caps, plastic shell labeling and so on.

III,the work process

* Core Working principle: The sensor detects the product in place or send product foot position signal, sucking down labeling tip labels and covered standard, then returned the next label in situ adsorption, wait for the next signal labeling, a label the attached action is completed.

* Procedure: put the product -> judgment in place (device detection control or manual control) -> Labeling and covered standard (device automatically) ->take out the labeling products.

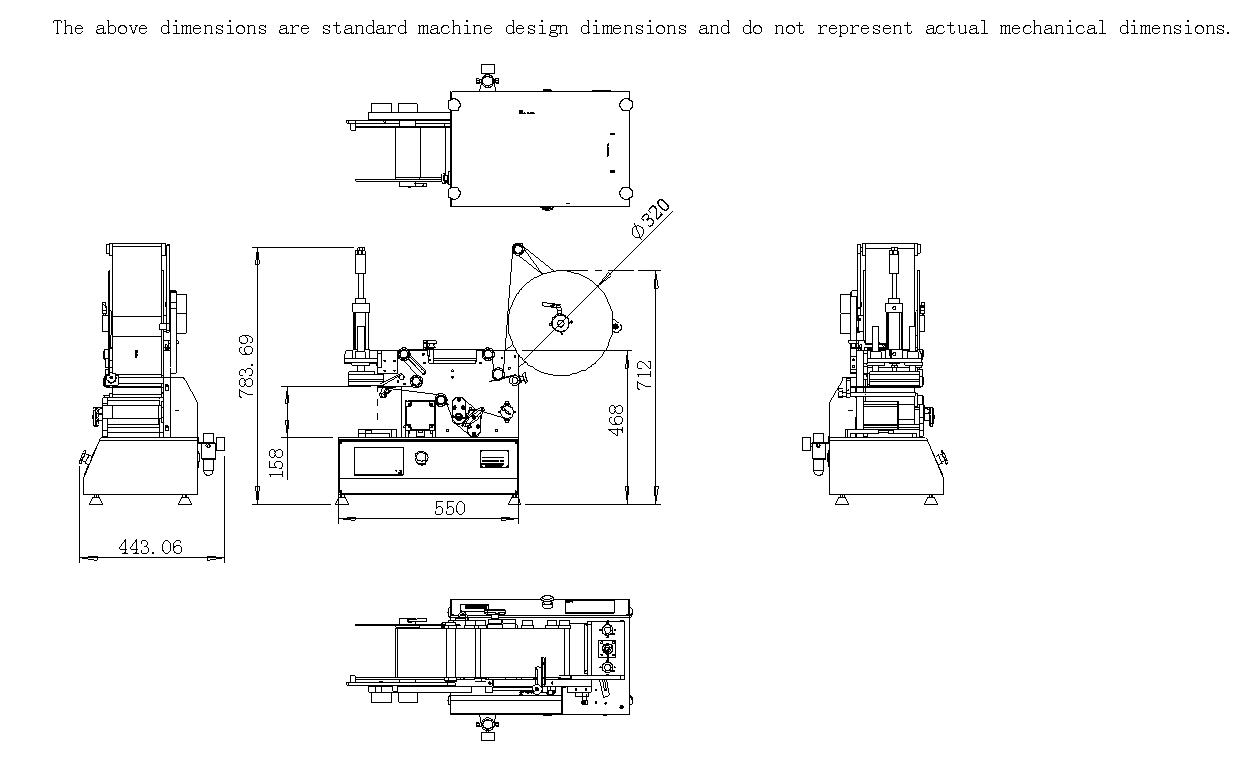

IV,Technical parameters: (The following technical parameters for the standard model, other special requirements and functions can be tailor-made)

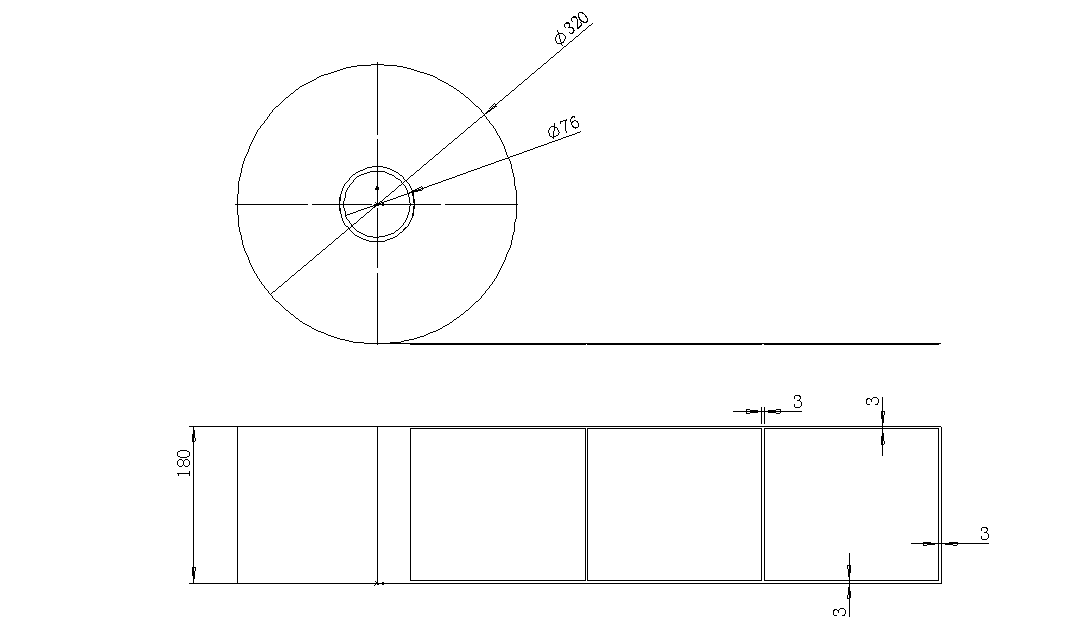

Applicable label length (mm): 15mm ~ 100mm

Applicable Label width (backing paper width / mm): 15mm ~ 150mm

Applicable Dimensions (length × width × height / thickness): Length: 20mm ~ 200mm

Width: 20mm ~ 150mm

Thickness: 0.2mm ~ 120mm

Applicable standard roll diameter (mm): φ320mm

Applicable standard roll diameter (mm): φ76mm

Labeling accuracy (mm): ± 0.5mm

The standard speed (m / min): 5m/min

Labeling speed (pcs / min): 20 ~ 45pcs/min

Weight (kg): about 48kg

Frequency (HZ): 50HZ

Voltage (V): 220V/110V

Power (W): 145W

Device dimensions (mm) (L × W × H): about 850mm × 410mm × 720mm

Pressure (Mpa): 0.4 ~ 0.6Mpa

V,Features

powerful, can be used in various parts of the flat, circular surface, the concave plane of labeling, labeling can be used for irregular workpieces;

accurate labeling, high stability, using PLC + standard stepper motor drive to send to send standard indeed; discharge institutions configurations brake function, to ensure standard belt taut, ensuring precise label detection; marked with detour corrective mechanism to prevent label offset about;

strong and durable, the circuit layout with separate gas, gas purification device configured to prevent moisture damage air appliances, prolong equipment life; machine using advanced aluminum and stainless steel materials, quality firm;

easy to adjust, height adjustable stroke configuration functions, different height product labeling, without repeated replacement fixture;

appearance, using bottom-mounted computer white box, with stainless steel and high-alloy, beautiful, lifting equipment level;

with manual / automatic two kinds of labeling control, workers may need to select the use of sensors to achieve labeling or foot control; setting manual and automatic control buttons, the standard length can be regulated;

Optional functions and components:

hot coding / marking function;

automatic feeding function;

automatic rewinding function (combination of product considered);

special label sensor.

Related Keywords