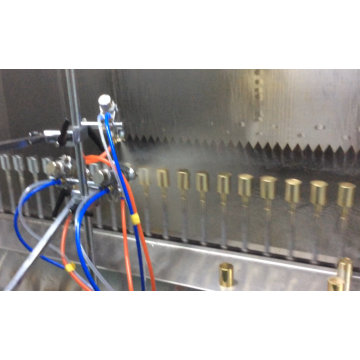

Automatic uv spray painting system

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500 |

| Supply Ability: | 50 |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | CE ISO |

| Transportation: | Ocean,Land |

Automatic UV spray painting system

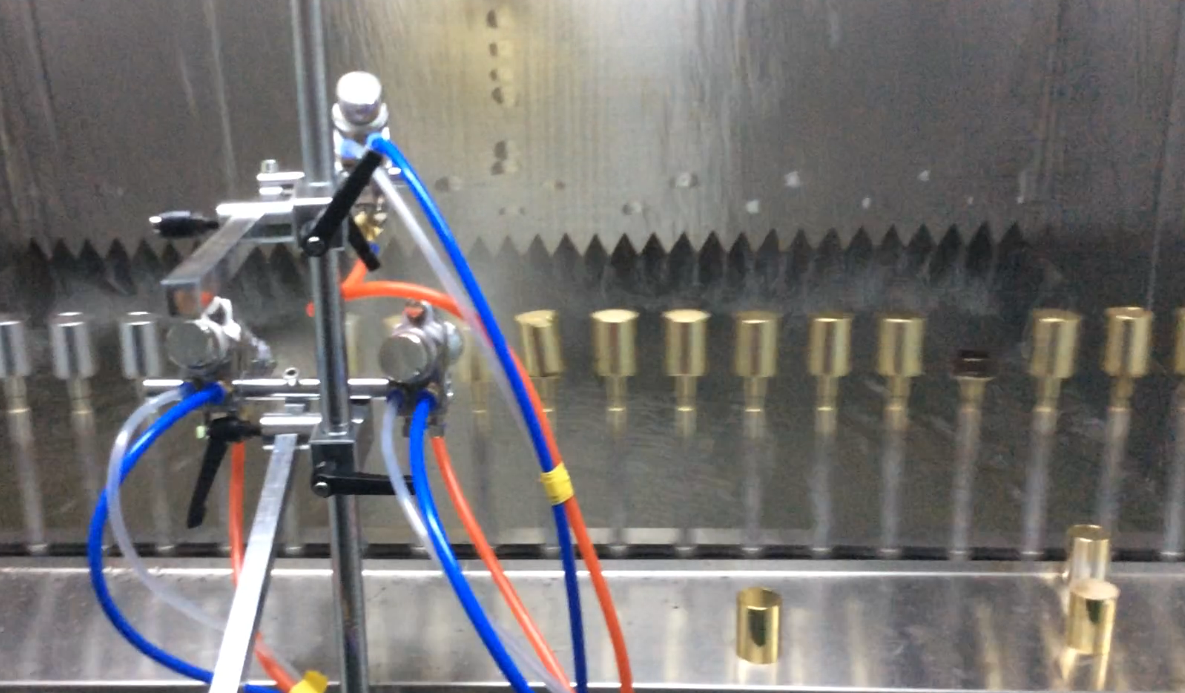

This type of uv spray painting system is widely used in plastic switch, mobile phone shell, camera shell, music player casing, toys, LCD screen, cosmetic caps, pen holder, bottle caps and so on. 95%, the quality remains stable.

Production Process:

Cleaning - loading - Preheating - Manual Dusting - Primer-UV base coating - Evaporation - Infrared Oven - Cooling - Dust - Topcoat (UV Coating) -Flashoff-IR Oven - UV Oven - Cooling -QC

Main components: electrostatic precipitator - spray table - Air Shower - fresh air system / air suction unit (AC drive) - Clean Room - conveyor system (AC drive) - infrared oven - UV oven - paint kitchen - Central water supply system (optional) - Exhaust gas treatment (optional) - Epoxy floor - Electrical control panel - Air compressor - Fire protection system

|

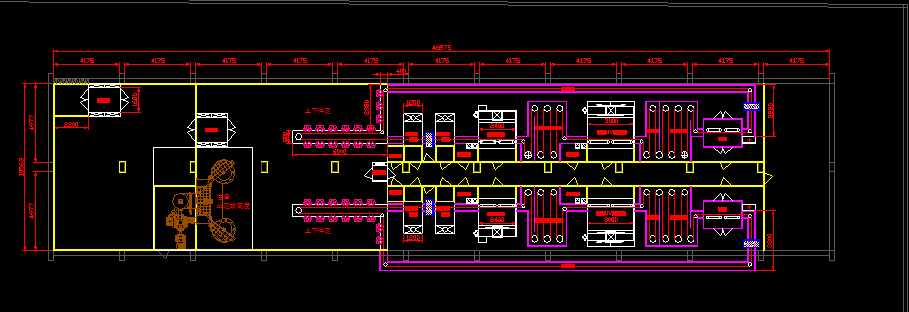

SPECIFICATIONS FOR UV COATING LINE

|

|||

|

Conveyor

|

Chainlink

|

Meter

|

205

|

|

Material

|

stainless steel

|

201/304

|

|

|

Structure

|

square tube

|

50*50

|

|

|

Spray Booth

|

Material

|

Stainless steel

|

201/304

|

|

Dimension

|

Meter

|

W3.0m×D3.0m×H2.1m

|

|

|

Work area

|

Meter

|

W2.9m×D2.0m×H1.4m

|

|

|

uv coating oven

|

Dimension

|

Meter

|

L2.5m*W1.8m*H2.8m

|

|

Light source:

|

Sets

|

5.6 KW UV lamp 4 sets, 3 KW UV lamp 2 sets;

|

|

|

Suction fan

|

Specification

|

3 kw centrifugal fan, air volume: 3119-4828 m3 / h;

|

|

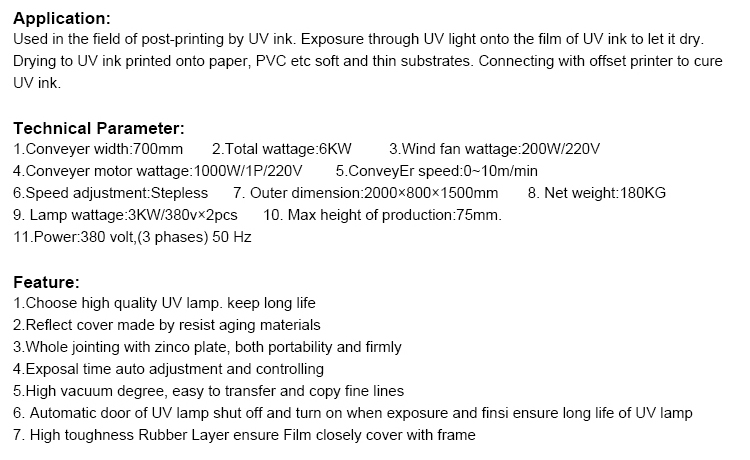

Introduction for main part of UV system:

UV system main body.

The UV system is specifically designed for curing light-cured coatings.

As UV curing at room temperature, suitable for a variety of items, do not need to directly heat, because it is a type of light curing.

In general, UV curing takes only 20 seconds, can save area, energy, investment and operating costs.

UV lamp life of 1500-2000h. In addition, 15-20% of the UV will disappear during the last period. Therefore, the reflector should be cleaned regularly.

Machine Parts

Name: uv coating line

Brand: HENG YI JIA

Original: China

one of the leading painting line suppliers in the painting/coating industry in China.Today,Shenzhen Heng Yi Jia Technology Co., Ltd. has been one of the top producers of quality automatic spray painting line and new technologies, such as: automatic spray painting line, UV coating lines (uv lines), mini auto painting line, spray chrome machine, and accessories of spray booth , equipment of vacuum metallizing machine(metallizer), Automatic UV plating vacuum line, spray booth, coating chain, Uv Curing Oven , automatic spray chrome equipment & line, spray Powder Coating Line & equipment and so on.

Main Features

1. With design and manufacturing experience more than 15 years

2. Installation experience for overseas

3.Brand electronic component for the line running

4.Pay attention to details to creating high value to customers

5.Save energy and paint

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Packaging

|

|

|

Size

|

40HQ

|

|

Weight

|

23 T

|

|

Packaging Details

|

The normal package film.for electronic components,we will use pe film for packing and pack in export wood polywood case which no need to fumigation

|

|

Packaging

|

|

|

Size

|

40HQ

|

|

Weight

|

18 T

|

|

Packaging Details

|

Film packing for all parts of customer's machine, we take care every part to avoid scratches

|

Please contact us

Related Keywords