Spray painting machine line for plastic products

-

$4550.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 20000pcs/h |

| Supply Ability: | 150 lines per year |

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN |

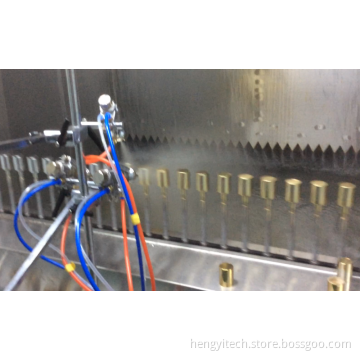

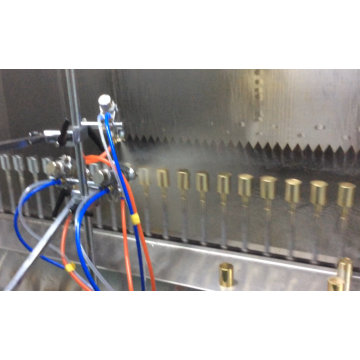

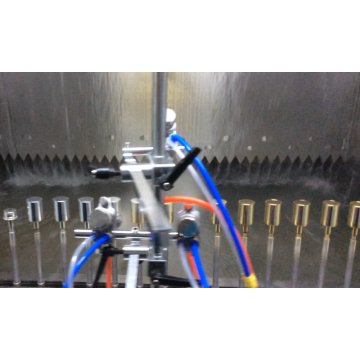

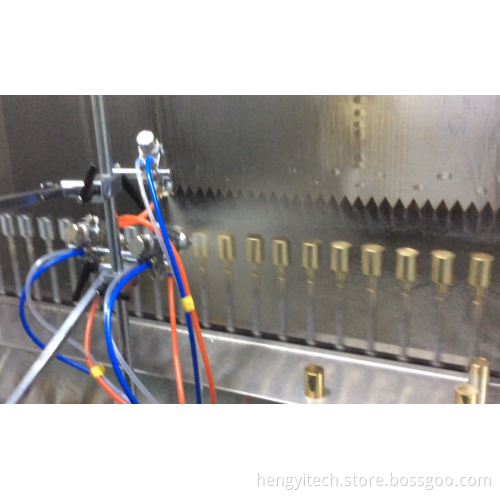

Plastic Product Spray painting line machine for plastic caps mobile case application:

Fully automatic spray painting production line for mobile phones, digital cameras, cosmetics, metal and plastic shell surface coating.

Fully automatic spray painting production line advantages.

Mobile phone painting line 100% spray painting evenly, 360-degree spray automatically and paint saving 30%Suitable for batch continuous production, high output, uniform coating surface; completely closed unmanned operation of spraying operations; production of high rate of qualified products, the production line, , The quality and stability; transmission chain and track contact with the precise configuration of the track bearing, running light and smooth, smooth and not jitters.

Related Products

Plastic Product Painting Line

Metal Product Painting Line

Glass Product Painting Line

Ceramic Product Painting Line

Wood ware Painting Line

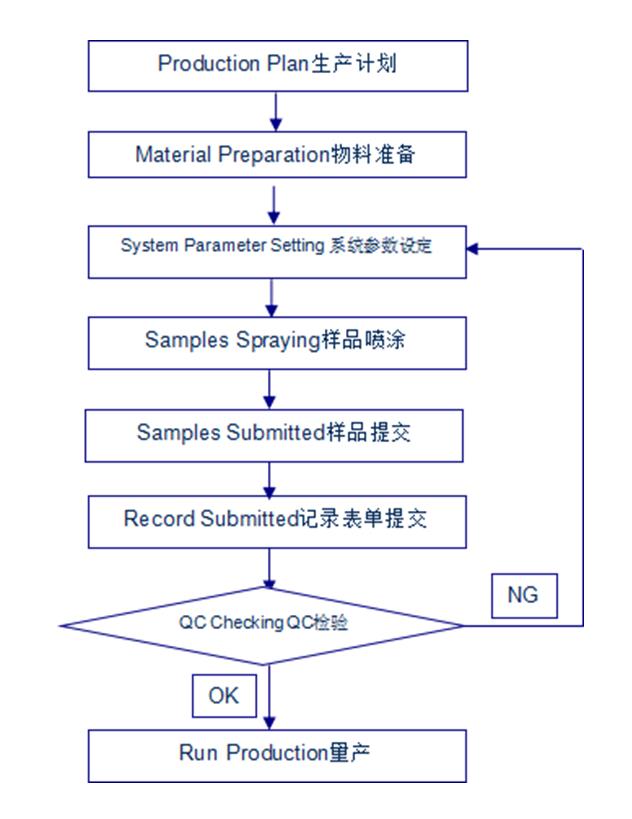

Painting Line Set Up Procedure

1 PURPOSE

This procedure describes the painting set up process and the methods used to monitor and control the operation of the painting process.

2 SCOPE

Flextronics Enclosures B10 High Volume Painting Line (ABB)

Flextronics Plastic B6 High Speed Painting Line (Iwata)

3 DEFININTION

FAI------First Article Inspection

4 REFERENCE

Master parameter record/parameter setting

Paint Mixing OI

TDS of paint

5 RESPONSIBILITY

5.1 Paining supervisor arrange own production schedule according to production schedule from planner , need to decide which line runs which part, and which technician and leader follow up.

5.2 Production technician is responsible to prepare the FAI sample and submit to QA.

5.3 QA is responsible to prepare the thickness and colour chip for production spray.

5.4 QA is responsible to check and approve the first painting sample. Make sure the quality of the products measure up to the quality requirement.

5.5 QA is responsible to prepare the FAI report.

6. PROCEDURE

6.1 Production schedule

Painting supervisor according to the production schedule which provided by planer to arrange the painting production schedule.

6.2 Material preparation

6.2.1 Raw part preparation

Production leader according to production plan to check the raw part is correct or not.

To check the quant

6.3.1.1 Robot system

a) According product to select the program for each robot

b) Base on product`s master parameter record to set atom, fan and flow rate of each brush

c) Check the gun position of each robot

d) Check the actual flow rate of each robot

e) Check the start point of each robot

f) Check the paint supply pump

Related Keywords