automatic spray painting cosmetic glass

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 40 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 38 |

| Supply Ability: | 8 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

UV Oven Features:

1. Fresh air filtration system with 10,000 clean levels of air supply.

2.UV oven work style: continuous work plus rotation.

Ultraviolet lamp distance adjustable.

4. Time function of UV oven working time.

5. Adjustable UV intensity.

6. When the UV oven is stopped, the ASU will be delayed.

7. UV lamp operating current, temperature alarm function.

8. The current of the suction and motor shows current overload.

9. Automatically check and adjust positive pressure.

10. UV oven automatic alarm.

What is the details of the HENGYIJIA-90m spray line

The same time as the above-1. The deposition rate is fast, the production efficiency is high, the coating has excellent brightness and good adhesion.

The same time as the above-

Intelligent automatic control, easy to operate, without any experience.

The same time as the above-

3. Environmental protection, no waste water and gas.

The same time as the above-

4. Through HENGYIJIA manufacturing the latest technology, but also through the CE and ISO international quality management system certification.

The same time as the above-

Specifications our HENGYIJIA-90m spray line

The same time as the above-

Automatic UV coating line

The same time as the above-

The same time as the above-

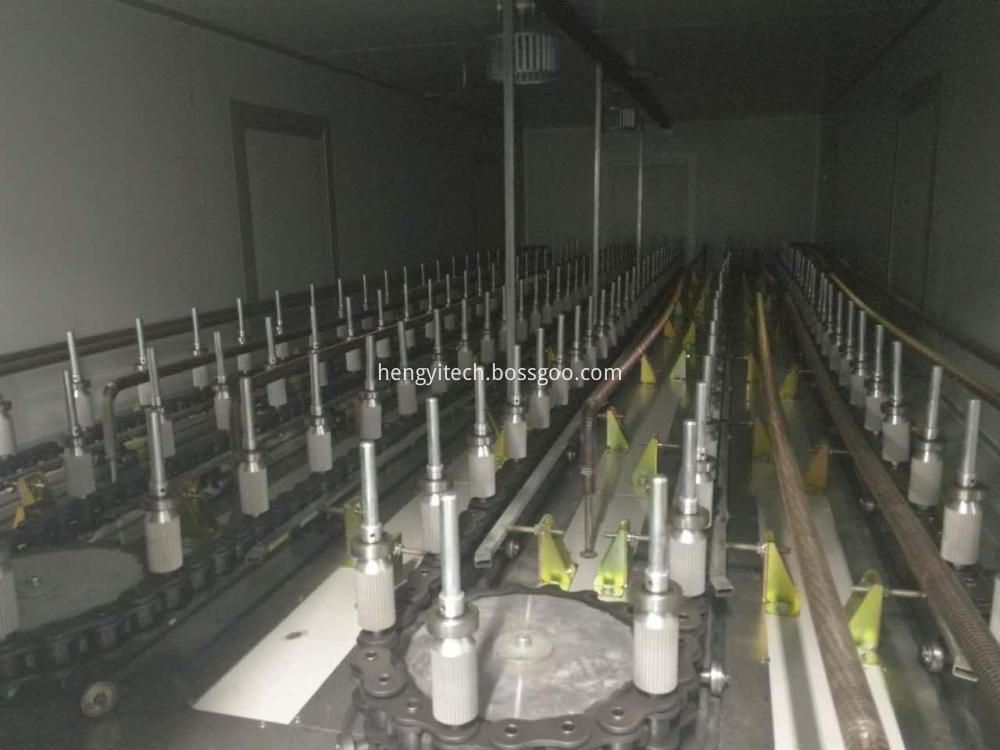

Main drive chain 90m

UV lamp fan 2.2kw (2 sets)

Spray fan 5.5kw 1 set

2 sets of spray booths (one for primer, one for finish)

UV light 5KW 6sets

Air filter 1 set of PLC: 1 set

Equipped with IR system

The same time as the above-

Perfume cap UV spray coating workshop technology and components (for reference only):

The same time as the above-

1. Process: Cleaning - Unloading - Preheating - Manual Dusting - Ionization - Primer - Evaporation - Infrared Oven - Cooling - Dust - Topcoat (UV Coating) -Flashoff-IR Oven - UV Oven - Cooling QC-

The same time as the above-

2. Main components: electrostatic precipitator - spray table - air shower - fresh air system / air suction unit (AC drive) - clean room - conveyor system (AC drive) - infrared oven - UV oven - paint kitchen - Central water supply system (optional) - Exhaust gas treatment (optional) - Epoxy floor - Electrical control panel - Air compressor - Fire protection system

The same time as the above-

application

This type of perfume bottle cap UV spray paint shop is widely used in mobile phone shell, camera shell, music player casing, toys, LCD screen, cosmetic caps, pen holder, bottle caps and so on. 95%, the quality remains stable.

The same time as the above-

Introduction UV oven:

UV oven main body.

The UV oven is specifically designed for curing light-cured coatings.

3. As UV curing at room temperature, suitable for a variety of items, do not need to directly heat, because it is a type of light curing.

In general, UV curing takes only 20 seconds, can save area, energy, investment and operating costs.

UV lamp life of 1500-2000h. In addition, 15-20% of the UV will disappear during the last period. Therefore, the reflector should be cleaned regularly.

The same time as the above-Product specifications

Certification ISO9001

2. after-sales service

3. Strong technical support

4. Size customization

5. Warranty: 1 year

Related Keywords