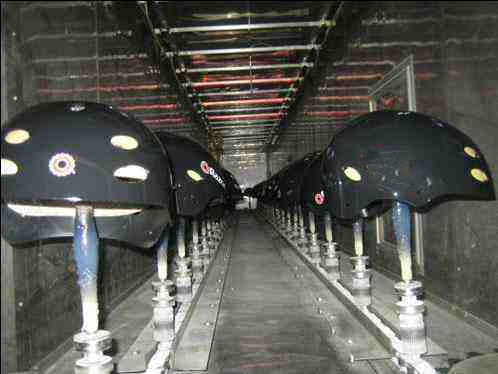

automatic coating machine for motorcycle helmet

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shekou, Yantian

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 40 |

| Supply Ability: | 7 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shekou,Yantian |

Product Description

Product Description

Product Application

This spraying mchine is professional design for motorcycle helmet coating. Its design depend on the shape and size , coating process of motorcycle helmet , we support Amercian GRACO 308 diaphram pump and Japanese ANEST IWATA air spray gun.

When the motorcycle helmet transported to the spray zone, the motorcycle helmet drived to continue rotating, then the machine start to spray, match the line speed. The machine can spray a large number of product with special fixture.

Clean automatic painting and plating helmet equipment:

1. With automatic gun spray paint shop

2. The paint room adopts HEPA filter

3. Automatic de-ion booth with automatic painting pavilion

4.10K clean room forcing automatic UV spray booth

5. Using SS304 automatic spraying workshop

6. Spindle conveyor belt with VFD control automatic painting room

7. Flash area, infrared oven and UV curing oven for UV spray booth

8. Automatic painting between different processes easy to transform

9. Air handling unit with automatic spray chamber filter

This spraying mchine is professional design for motorcycle helmet coating. Its design depend on the shape and size , coating process of motorcycle helmet , we support Amercian GRACO 308 diaphram pump and Japanese ANEST IWATA air spray gun.

When the motorcycle helmet transported to the spray zone, the motorcycle helmet drived to continue rotating, then the machine start to spray, match the line speed. The machine can spray a large number of product with special fixture.

Clean automatic painting and plating helmet equipment:

1. With automatic gun spray paint shop

2. The paint room adopts HEPA filter

3. Automatic de-ion booth with automatic painting pavilion

4.10K clean room forcing automatic UV spray booth

5. Using SS304 automatic spraying workshop

6. Spindle conveyor belt with VFD control automatic painting room

7. Flash area, infrared oven and UV curing oven for UV spray booth

8. Automatic painting between different processes easy to transform

9. Air handling unit with automatic spray chamber filter

10. The vacuum metallization of the automatic spray booth is optional.

Related Keywords

Related Keywords