Oil free screw air compressor overhaul service for Atlas copco

- Delivery Time:

- 20 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

With the stable and mature technology, we provide strong overhaul security for majority of oil-free compressor user, make the oil-free machine normal and efficient operation; fruitful achieved recognition of client who cooperate with us; and occupy absolute advantage in the domestic market.

If your oil-free machine (Air end) head has not been repaired, we can help you to restore to the original factory standard, welcome your order!

Why you choose us to repair? 1. We have professional maintenance technology for many years, a comprehensive technology; we can do oil-free machine overhaul for atlas copco, Ingersoll-rand, Sullair and other brand compressor. Of course, if you have any questions for oil- injected air compressor overhaul, you can consult with us anytime; we can help you very convenient.

2. Please don’t worry about these problems, which machine head will be not repair well and you lose money. As we don’t collect your money if we don’t repair well, and will refund the shipping cost also.

3. Concessional price; our price is lower than the market price, in our first cooperation; the price can be decided by customers. We repair machine head, our customers are very satisfied, and we let the user to establish confidence in our technical strength in the first time.

4. Here is the global maintenance base, sincerely welcome the world's customers who have oil free machine, we need a number of customers, and we offer members of the service.

5. If you want have a national technical comprehensive and top technology of the engineer circle, want to know more about joining our joyliwin maintenance platform and maintenance base, please add us WhatsApp:+8613802584547 The difference with other company. Other company do maintenance, I do maintenance platform

Other companies do unit customers; I do a collection and the League

Other companies quote price according to requirements; we price these by ourselves.

I suggest you join us!

Because even if you do not understand technology of oil free machine, we have the professional engineer provide full service for you

You just need to find a customer; the interest is related to you in the future.

If you understand the technology, you can also have a higher level of engineer to help you make your career like a tiger with wings. Customers can see the interests

1. You don't have to worry about maintenance technology; During overhaul period, we analyze and discuss the problems that arise, and provide a strong and orderly guarantee to solve the problem. Our professional overhaul procedure pays more attention to the rigorous work style, pragmatic quality control process, make overhaul work more standardized. In the overhaul process, we have a full range of measurement of the screw in the main engine of the compressor to ensure the physical dimension precision can meet the original factory level after repair. 2. Professional technology and equipment; We will combine the dynamic balancing machine, three coordinate positioning equipment, special ultrasonic cleaning machines and spraying equipment, precision machine tools and other special equipment, to restore the damage to the site for precision.

3. You don't need to worry about service;

You don't need to worry about management: in the segment of overhaul for main machine, we pay more attention to both of quality and specialty, strictly regulate the import registration procedures guarantee the overhaul period and quality, to promote cooperation deeply between our company and customers who needs air end overhaul, and achieved long-term development.

The oil free compressors have the following advantages:

1. Oil-free compressor can provide high quality compressed air without oil and water, can meet demand of some special occasions, and expand the scope of the use of air compressors.

2. Steady Flow: Generally, oil free compressor using the latest pressure device, can ensure the output air constant current voltage. When oil-free machines are used in the laboratory, it can improve the precision of some experimental instruments.

3. Operation Easily: Eliminating the problem of exchange and add the lubricating oil, simplifying the use step of air compressor, extending maintenance cycle of air compressor, it makes operation more simple.

4. Low Noise: Generally, the oil-free compressor is silent oil free compressor, noise is very small. It will not affect the surrounding environment, and be beneficial to work for the operators.

5. Saving Energy: If you use oil-free air compressor to provide the compressed air, it will not reduce motor load greatly due to pressure loss from oil removal equipment, and to achieve energy efficiency.

If you do not have professional engineer to help you solve the problem of overhaul of oil-free machine, and if you have any need of terminal maintenance for oil-free screw air compressor, please kindly contact our service person,

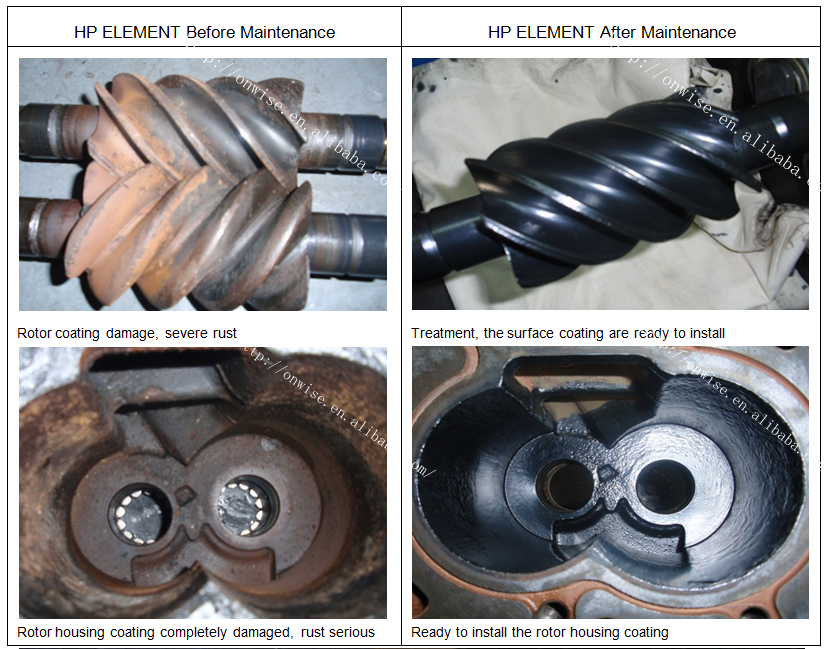

Skype: sunnyoste / joyliwin or call: +8613802584547 Pictures of Contrast before and after repair

Working Description | |

1. | Decomposition of the rotor, cleaning all parts |

2. | Screw surface coating of female rotor and male rotor, and the grinding process for coating |

3. | Dynamic balance of female rotor and male screw test |

4. | of the rotor housing for spraying , grinding |

5. | Female screw and male screw and the case will be carried out with the ground screw, and adjust the gap |

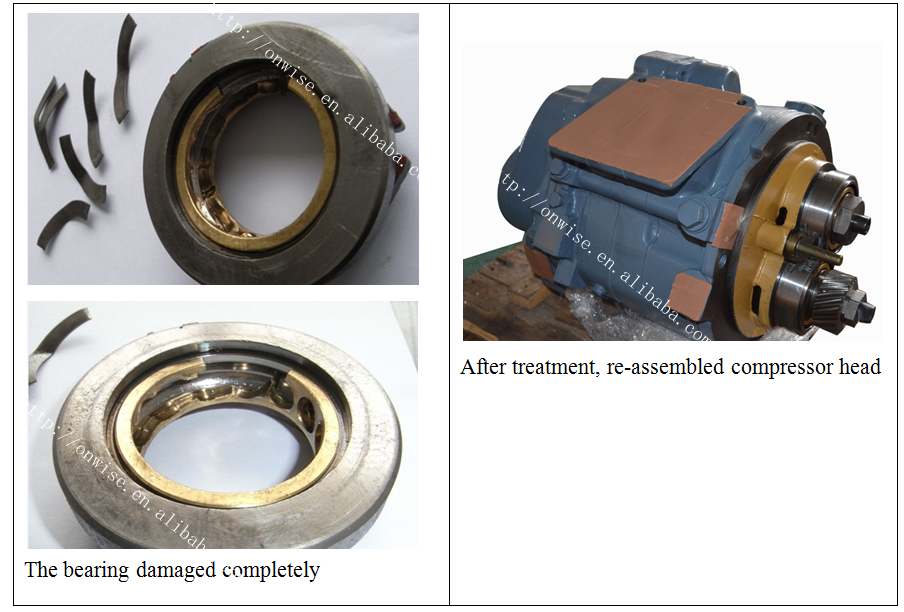

6. | According to our standard procedures and requirements to replace a full set of bearings, seals , oil seals and other components, adjust the gap between the parts, re-assembly of the rotor ok |

7. | General cleaning of the shell exterior, painting, packaging |

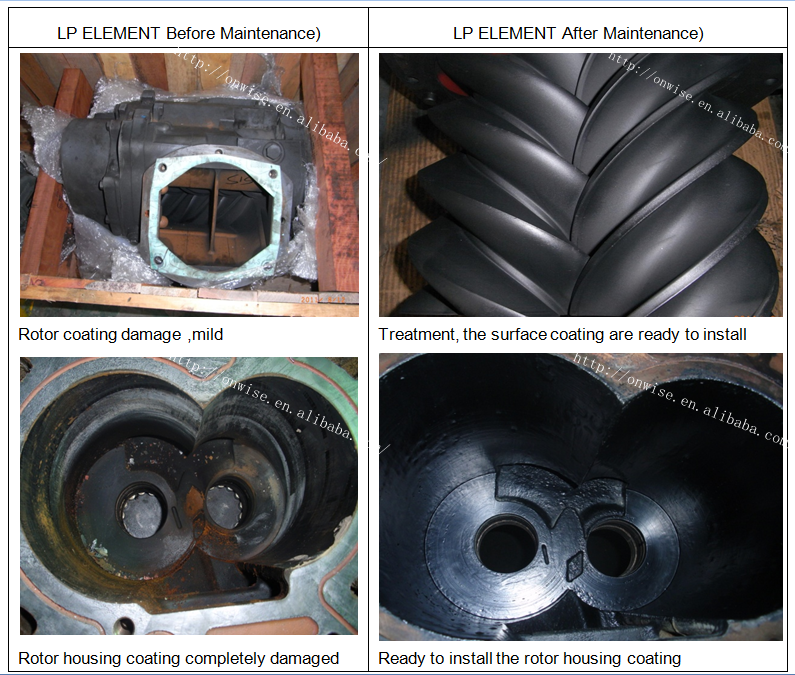

The above mentioned are comparison pictures before and after maintenance for low pressure rotor, balancing test data are as follows 1,Female and male rotor balancing test , installation, gap adjustment, replacing worn parts 2,The test results is rotor manually running normal , no noise inside 3,Balancing test standard and results analysis Type YYQ-80 hard bearing balancing machines be used to test and measure the balancing of female and male rotor, using graphic supporting method, selection removing the gravimetric method. Notice: The equipment must be installed and debugged by the professional engineers specialized in oil-less air compressor, after complete installation, point-start the host to ensure that gearbox oil supply is sufficient , running unloading more than twenty minutes to ensure the surface breakingin of the rotor, then load operation.

The above mentioned are comparison pictures before and after maintenance for low pressure rotor, balancing test data are as follows 1,Female and male rotor balancing test , installation, gap adjustment, replacing worn parts 2,The test results is rotor manually running normal , no noise inside 3,Balancing test standard and results analysis Type YYQ-80 hard bearing balancing machines be used to test and measure the balancing of female and male rotor, using graphic supporting method, selection removing the gravimetric method. Notice: The equipment must be installed and debugged by the professional engineers specialized in oil-less air compressor, after complete installation, point-start the host to ensure that gearbox oil supply is sufficient , running unloading more than twenty minutes to ensure the surface breakingin of the rotor, then load operation.

OTHERS FOR REFERENCE ATLAS COPCO Standard major overhaul detailed work content(FOR OIL COMPRESSOR ALSO)

OTHERS FOR REFERENCE ATLAS COPCO Standard major overhaul detailed work content(FOR OIL COMPRESSOR ALSO) A,Overhaul replacement parts Details | B,Measurements |

Replace the screw drive bearing positioned at both ends | Balancing test female and male treaded rod |

Replace the host mechanical shaft seal, oil seal | Mounting precision measurement , female and male treaded rod |

Replace the host gasket | Pecision gap measurement, female and male treaded rod |

Replace the host rotor compound gasket | Precision axial gap measurement, female and male treaded rod |

Replace gap-adjustment gasket | Precision radial clearance measurement , female and male treaded rod |

Replace the seal , seal sleeve | Curve Precision measurement, female and male treaded rod |

Bearing installation position precision measurement |

|

C,Adjustments | D,Installation complement, whole equipment surface treatment |

Radial clearance adjustment, female and male threaded rod | Whole equipment paint treatment performed |

The axial clearance adjustment, female and male threaded rod | Cleaning the outer valves |

Bearing installation precision adjustment |

|

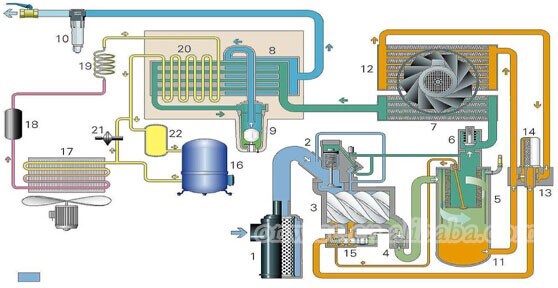

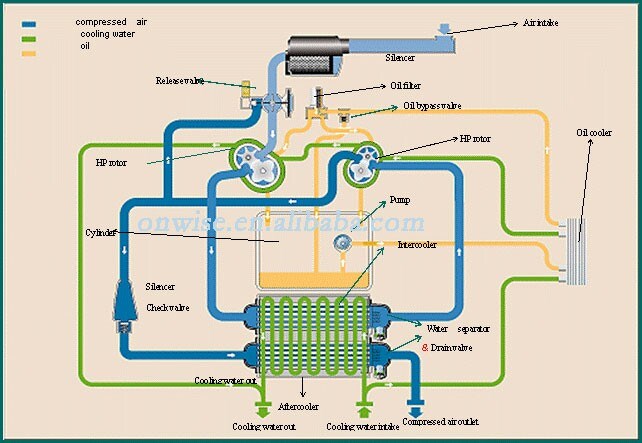

2. Work flow chart two-stage oil-injected screw compressors

2. Work flow chart two-stage oil-injected screw compressors  3.work flow chart two-stage oil-free screw compressors

3.work flow chart two-stage oil-free screw compressors  Atlas copco oil-free air compressor overhaul Ingersoll Rand oil-free air compressor overhaul Sullair oil free air compressor overhaul Major overhaul service, Type oil-free screw air compressor

Atlas copco oil-free air compressor overhaul Ingersoll Rand oil-free air compressor overhaul Sullair oil free air compressor overhaul Major overhaul service, Type oil-free screw air compressor Oil free screw air compressor air-end overhaul Major overhaul service, Type oil-free screw air compressor head

Oil free compressor main machine overhaul Terminal Maintenance, Type oil-free compressor

Oil free machine terminal maintenance Terminal Maintenance, Type oil-free screw compressor Oil free screw compressor terminal maintenance Terminal Maintenance for oil-free screw compressor Oil-free compressor Major overhaul service Oil-free air compressor air-end overhaul Major overhaul service, Type compressor host

Major overhaul service, Type compressor head

Maintenance and Major overhaul service, Type Atlas Copco oil-free compressor, Model ZR110 ZR132 ZR145 ZR160 ZR200,ZR250,ZR315,ZR355 Air compressor spare parts Atlas oil free air compressor overhaul Major overhaul service, Type Ingersoll Rand oil-free air compressor, Model: IRN90K 160-0F IRN125H 200H-0F Major overhaul service, Type Sullair oil-free air compressor

Main machine overhaul for air compressor Compressor machine head overhaul service Maintenance and maintenance of oil free screw air compressor How to maintain for oil free screw air compressor How to repair for oil free screw air compressor Air end repair Air filter Oil filter Air-oil separator Air compressor spare parts wholesale Packaging & Shipping Packaging: Carton,Wooden cases, Plastic bag,ect, make the package as your requested.

Shipping: Send goods by International Express, by Air, by sea, etc. If you have a forwarder, you can arrange this by your side. We offer EX-Work service.

Our Services Applied Brands: Atlas Copco, Ingersollrand, Sullair, Fusheng, etc. Business Scope: Electrical Components Valve Series; Preventive Maintenance Kit Series; Auxiliary Equipment Daily Consumables Series; (Air filter,oil filter, oil separator replacement) Common Easily Worn Components Series;

Our Services Applied Brands: Atlas Copco, Ingersollrand, Sullair, Fusheng, etc. Business Scope: Electrical Components Valve Series; Preventive Maintenance Kit Series; Auxiliary Equipment Daily Consumables Series; (Air filter,oil filter, oil separator replacement) Common Easily Worn Components Series;  Company Information

Company Information  Shenzhen Joyliwin S&T Co., Ltd. mainly deals with all kinds of screw air compressor parts in China. We can supply these products in large quantities. As one of the biggest exporters for screw air compressor parts, aiming at helping customers get more profitable by providing quality equipment at less cost, we test every item by our QC department before delivery.

Shenzhen Joyliwin S&T Co., Ltd. mainly deals with all kinds of screw air compressor parts in China. We can supply these products in large quantities. As one of the biggest exporters for screw air compressor parts, aiming at helping customers get more profitable by providing quality equipment at less cost, we test every item by our QC department before delivery.

FAQ

FAQ  Q: Why do you choose us? A:1)12years experience in air compressor parts area 2) temperature sensor have been provided to 2,000 customer in domestic and oversea customers 3) high work effiency

Q: Why do you choose us? A:1)12years experience in air compressor parts area 2) temperature sensor have been provided to 2,000 customer in domestic and oversea customers 3) high work effiency4) reasonable in opening and closing design

5) original temperature sensor manufacturer and supplier 6) seriously quality control

Related Keywords