Building Coating Usage and Liquid Coating State Concrete Penetrating Sealer

- Delivery Time:

- 7 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

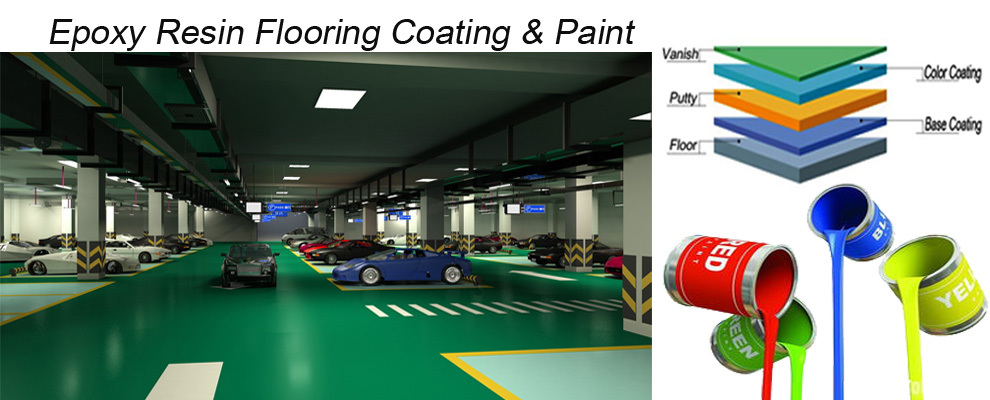

Instruction Features It is a kind of high cleanliness ground adornment material, smooth bright and can meet the requirements of high cleanliness Wide application

Instruction Features It is a kind of high cleanliness ground adornment material, smooth bright and can meet the requirements of high cleanliness Wide application  Widely used in electronics, precision instruments, hardware factory, mold factory, warehouse, underground garage,office ,living room ,bedroom etc. Have high request for the ground. Technical Data Sheet Base Technical Data Sheet

Widely used in electronics, precision instruments, hardware factory, mold factory, warehouse, underground garage,office ,living room ,bedroom etc. Have high request for the ground. Technical Data Sheet Base Technical Data Sheet Item | Epoxy Resin Glue for Cement Floor Coating |

Main Material | Epoxy resin ,hardener,pigments,thinner and so on . |

Appearance | Clear and matte type for your choice |

Coating Thickness | 0.5-0.7mm,you can adjust according to your situation |

Using life | More than 5 years |

Color | Clear ,green and grey and can do as your requirements . |

2. On the clean cement floor, coat the glue on the ground with a trowel to stir large batch on the coat, the local corner, outlet available with small scraper blade coating.According to your own situation to decide the coating times to gain the effect of being smooth and no holes, no batch of knife is printed and frosted.

3. According to the room temperature to confirm the cure time (6 hours in common) ,after being completely cured, carefully check whether there is any bump, if have on the ground and necessary,polish with Angle mill grinding and dust collection, shall be for the following process. Technical Index Technical Index

Item | Figures |

Compressive Strength(Mpa) | ≥85 |

Bending Strength(Mpa) | ≥40 |

Tensile Strength(Mpa) | ≥9 |

Impact Resistance(kg.cm) | ≥50 |

Flow Property(min) | ≥8 |

Surface Coating Density(g/cm³) | 1.3±0.1 |

Water Resistance(30days)/Oil Resistance(72h) | No Changing |

Curing Time (h) | ≤6 |

Drying Completely(h) | ≤24 |

1.Cement Floor Treatment | Polish your cement floor ,then clean the dust |

2.Base Glue Coating | The adoption of permeability and strong bottom coating epoxy resin coating adhesion, enhanced adhesion at a time |

3.Middle layer glue coating | Coating for 1-2 times, according to the actual needs of construction requirements to flat light, no hole, no grinding crack |

4.Top layer glue coating | Using customer specified color epoxy resin coating, roller coating floor, completed the whole ground color uniform, bright and clean, no empty drum |

Before the Construction Approach 1) surface smooth, no uneven, wait for a phenomenon.On the surface of the PH value between 20% to 75%.

2) at the grass-roots level moisture content should be less than 8%.

Construction Quality Specification 1) Ensure the floor color is rich, the overall is seamless and easy to clean

2)Has high bonding strength with the hardening the ground at the grass-roots level, no crack after hardening.

3) The whole ground is smooth and bright, color is rich, can beautify the work environment.

OEM Service You can buy the transparent glue,then mix with various pigments color as you prefer ,then make the colorful finished floor . Here is the color swatches for your reference .

Related Products

Related Products

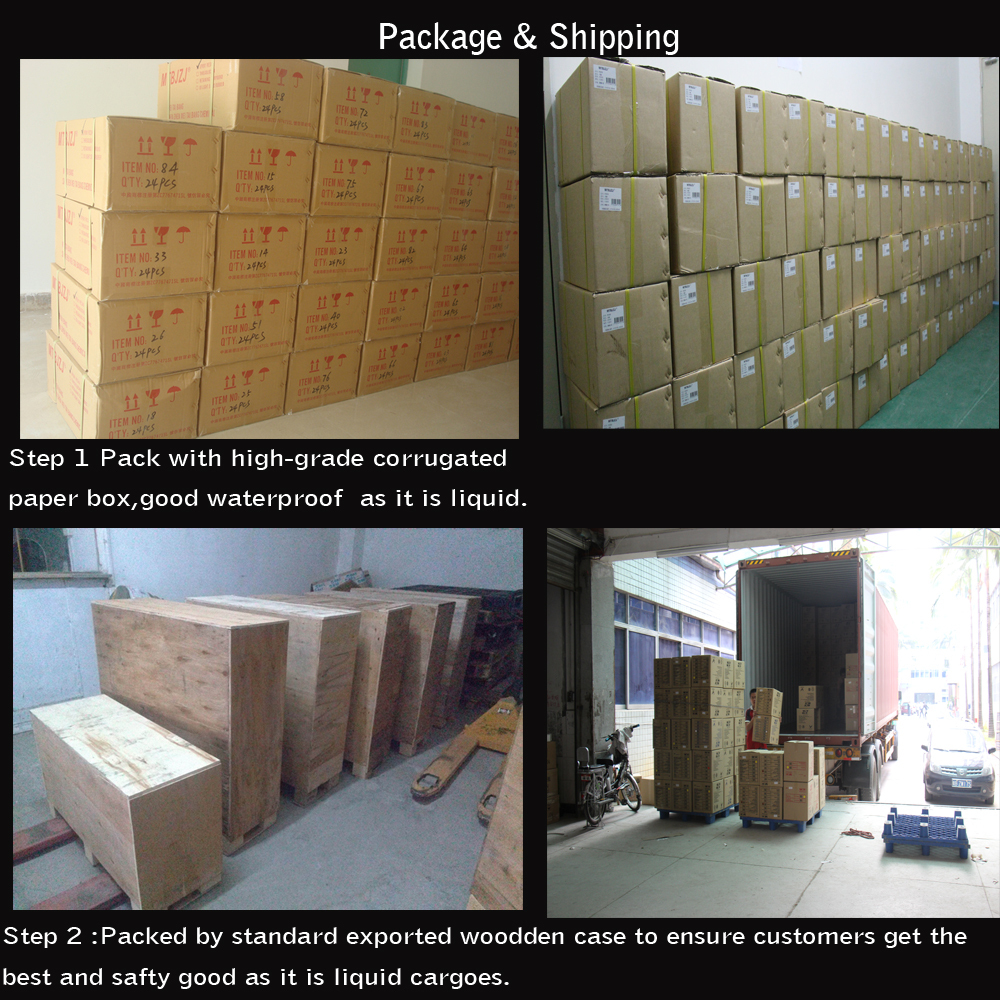

Packaging & Shipping For epoxy resin AB glue ,the packing of our own is 8kgs/set,and 40kgs/set ,and we can do the packing as your designs and requirements.

Packaging & Shipping For epoxy resin AB glue ,the packing of our own is 8kgs/set,and 40kgs/set ,and we can do the packing as your designs and requirements.

Related Keywords