Transparent Long Open Time Low Viscosity High Tack PUR Hot Melt Adhesive for Mobile Phone and Tablet Assembly

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Product Description High performance PUR Hot Melt Adhesive for lens/case and housing assembly in cell phones and notebooks, MP3 players, portable batteries, and other consumer electronics

Instruction One component, moisture curing, urethane adhesive that is applied warm,and sets like a hot melt adhesive, but with a long open time for easy assembly of parts requiring a thin bond line.Specially designed for electronic components installation.It is solid at room temperature, heating when use,then coating, after the completion , will have good reaction with the the surrounding environment moisture to gain the best bonding effect Don't need additional heating during the reaction process, quick bond. This low viscosity adhesive has a long open time and is ideal for bonding plastics. Yields thin glue lines when used with appropriate equipment. Features Features • 100% solids • Long open time • Bonds a variety of plastics • One component • High tack • Reworkable after cured • Low viscosity • High strength bonds • High impact resistance • Excellent heat resistance • Excellent waterproof • Excellent temperature and weather humidity resistance • Can not be soak off even in the water for a long time • ROHS/without halogen/non-phosphoru/no benzene Typical Uncured Prop Typical Uncured Properties Note: The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

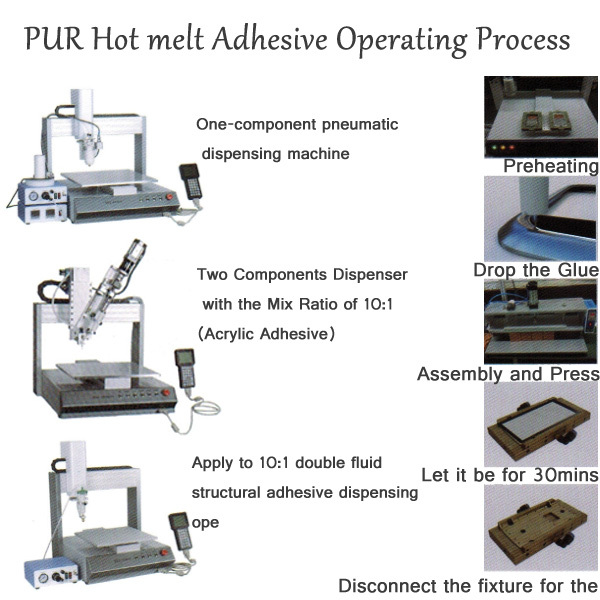

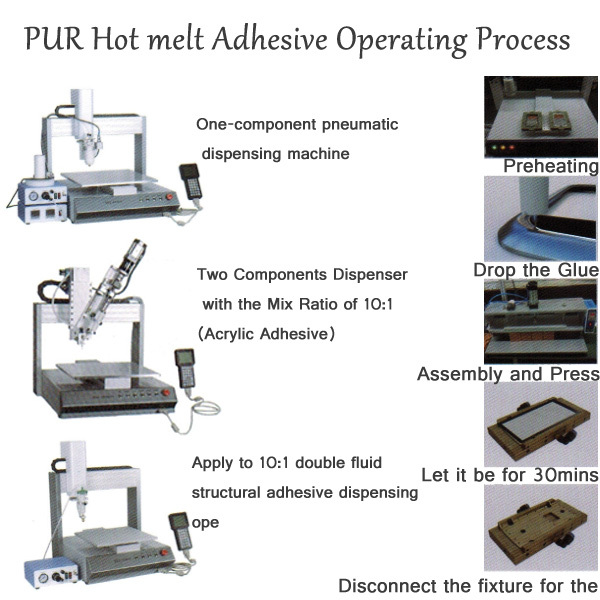

Measured on Brookfield viscometer with Thermosel using spindle #27. The upper limit for bonding a 1/16" bead of molten adhesive on a plastic substrate in a room temperature environment. Open time is related to the solidification of the molten adhesive. The minimum amount of time required between when a 1" x 1" bond is made and when it will support a 5 psi tensile load on polycarbonate (PC) substrates. Open times and set times are based on a room temperature environment. High temperatures will lengthen open times and set times while lower environmental temperatures will shorten open times and set times. Operating Process PUR Hot melt Adhesive Operating Process Remove the scabby glue ,install the needle, with the operation time ≤2mins 1. Preheating 2. Drop the Glue 3. Assembly and Press 4. Let it be for 30mins 5. Disconnect the fixture for the next assembly  Disassembly process While heating, applying external force is the effective method of heavy Industry 1. For bonding the LCD module and the border, heated for 5 to 15 minutes @65-80 ℃, while applying for 5-10 kg force (thrust and pressure), so it is easy to separate parts 2. Clean with mild solvent to wipe off the residue glue on the LCD module (such as isopropyl alcohol, n-heptane, etc.), avoid solvent into the LCD module to cause damage 3. Suitable heavy industry system will greatly improve efficiency 4. It is better to test LCD module whether also can work normally after the heating, to modify the heating temperature and external force size according to it. Typical Application Typical Application High performance for lens/case and housing assembly in cell phones and notebooks, MP3 players, portable batteries, and other consumer electronics • Thin, tough and flexible bond lines help improve fit, appearance,and reliability. • Excellent high strength bonds for plastics and metals, dissimilar substrates, and even hard-to-bond plastics such as polycarbonate. • No whitening, as often occurs with cyanoacrylate adhesives on plastic. • No plastic cracking, as may occur with ultrasonic welding Handling/Application Information Directions for Use Apply to clean, dried surfaces. Remove oil, grease and other contaminants by wiping with isopropyl alcohol. For materials that are often contaminated with mold release agents, it is recommended that the surface be solvent wiped, abraded and solvent wiped. For additional information on surface preparation, see section on Surface Preparation. • For best results, heat the syringe a minimum of 30 minutes at 110°C (230°F) before using. • Apply adequate amount of adhesive to one of the substrates to be bonded. Join the substrates within the adhesive’s specified open time and hold the bonded part until the adhesive has adequately set. Note: When using solvents, extinguish all ignition sources, and follow the manufacturer’s precautions and directions for use. Detailed Images

Disassembly process While heating, applying external force is the effective method of heavy Industry 1. For bonding the LCD module and the border, heated for 5 to 15 minutes @65-80 ℃, while applying for 5-10 kg force (thrust and pressure), so it is easy to separate parts 2. Clean with mild solvent to wipe off the residue glue on the LCD module (such as isopropyl alcohol, n-heptane, etc.), avoid solvent into the LCD module to cause damage 3. Suitable heavy industry system will greatly improve efficiency 4. It is better to test LCD module whether also can work normally after the heating, to modify the heating temperature and external force size according to it. Typical Application Typical Application High performance for lens/case and housing assembly in cell phones and notebooks, MP3 players, portable batteries, and other consumer electronics • Thin, tough and flexible bond lines help improve fit, appearance,and reliability. • Excellent high strength bonds for plastics and metals, dissimilar substrates, and even hard-to-bond plastics such as polycarbonate. • No whitening, as often occurs with cyanoacrylate adhesives on plastic. • No plastic cracking, as may occur with ultrasonic welding Handling/Application Information Directions for Use Apply to clean, dried surfaces. Remove oil, grease and other contaminants by wiping with isopropyl alcohol. For materials that are often contaminated with mold release agents, it is recommended that the surface be solvent wiped, abraded and solvent wiped. For additional information on surface preparation, see section on Surface Preparation. • For best results, heat the syringe a minimum of 30 minutes at 110°C (230°F) before using. • Apply adequate amount of adhesive to one of the substrates to be bonded. Join the substrates within the adhesive’s specified open time and hold the bonded part until the adhesive has adequately set. Note: When using solvents, extinguish all ignition sources, and follow the manufacturer’s precautions and directions for use. Detailed Images

Packaging & Shipping For PUR hot melt adhesive,our packing is 30ML/PC,2pcs/bag,120pcs /carton .and we can do the packing as your requirements and designs . Our Service Why choose us ? 1. Professional manufacturer & long history We are direct manufacturer of glue and adhesive since 1998.So We have Professional production team, production line, experienced technical experts also much experiences and higher skills to ensuring product quality and deliver in time with a very short time . 2. Competitive quality &factory price 3. Our market Our customer all over the world . Main market in Europe ,South America,Australia and Asia ,such as Vietnam,Thailand , Malaysia and so on . We gained good reputation in the industry because our various items made of imported raw material, good workmanship and fast delivery time. 4. Custom design welcome Customer logo /design/OEM welcome .So our products always so creative&innovative . 5. Best service We keep every customer for long time business.We regard every one as our VIP,no matter small or big order .

Packaging & Shipping For PUR hot melt adhesive,our packing is 30ML/PC,2pcs/bag,120pcs /carton .and we can do the packing as your requirements and designs . Our Service Why choose us ? 1. Professional manufacturer & long history We are direct manufacturer of glue and adhesive since 1998.So We have Professional production team, production line, experienced technical experts also much experiences and higher skills to ensuring product quality and deliver in time with a very short time . 2. Competitive quality &factory price 3. Our market Our customer all over the world . Main market in Europe ,South America,Australia and Asia ,such as Vietnam,Thailand , Malaysia and so on . We gained good reputation in the industry because our various items made of imported raw material, good workmanship and fast delivery time. 4. Custom design welcome Customer logo /design/OEM welcome .So our products always so creative&innovative . 5. Best service We keep every customer for long time business.We regard every one as our VIP,no matter small or big order .

Instruction One component, moisture curing, urethane adhesive that is applied warm,and sets like a hot melt adhesive, but with a long open time for easy assembly of parts requiring a thin bond line.Specially designed for electronic components installation.It is solid at room temperature, heating when use,then coating, after the completion , will have good reaction with the the surrounding environment moisture to gain the best bonding effect Don't need additional heating during the reaction process, quick bond. This low viscosity adhesive has a long open time and is ideal for bonding plastics. Yields thin glue lines when used with appropriate equipment. Features Features • 100% solids • Long open time • Bonds a variety of plastics • One component • High tack • Reworkable after cured • Low viscosity • High strength bonds • High impact resistance • Excellent heat resistance • Excellent waterproof • Excellent temperature and weather humidity resistance • Can not be soak off even in the water for a long time • ROHS/without halogen/non-phosphoru/no benzene Typical Uncured Prop Typical Uncured Properties Note: The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

Item | Appearance | Component | Viscosity (CPS) | Operating Time (min) | Set Time (min) | Tensile Rate % | Temperature | Pack |

MTB-7580 | Light Yellow Solid | Single | 5000-6000 @100°C | 1-2 | 30 | 100-125 | -40-100 C° | 30ml/cartridge in vacuum Package |

MTB-7582 | Black Solid | Single | 5000-6000 @100°C | 1-2 | 30 | 100-125 | -40-100 C° | |

MTB-3542 | Clear/off white | Single | 6000-7000@120°C | 1-2 | 1-4 | 100-125 | -40-100 C° |

Disassembly process While heating, applying external force is the effective method of heavy Industry 1. For bonding the LCD module and the border, heated for 5 to 15 minutes @65-80 ℃, while applying for 5-10 kg force (thrust and pressure), so it is easy to separate parts 2. Clean with mild solvent to wipe off the residue glue on the LCD module (such as isopropyl alcohol, n-heptane, etc.), avoid solvent into the LCD module to cause damage 3. Suitable heavy industry system will greatly improve efficiency 4. It is better to test LCD module whether also can work normally after the heating, to modify the heating temperature and external force size according to it. Typical Application Typical Application High performance for lens/case and housing assembly in cell phones and notebooks, MP3 players, portable batteries, and other consumer electronics • Thin, tough and flexible bond lines help improve fit, appearance,and reliability. • Excellent high strength bonds for plastics and metals, dissimilar substrates, and even hard-to-bond plastics such as polycarbonate. • No whitening, as often occurs with cyanoacrylate adhesives on plastic. • No plastic cracking, as may occur with ultrasonic welding Handling/Application Information Directions for Use Apply to clean, dried surfaces. Remove oil, grease and other contaminants by wiping with isopropyl alcohol. For materials that are often contaminated with mold release agents, it is recommended that the surface be solvent wiped, abraded and solvent wiped. For additional information on surface preparation, see section on Surface Preparation. • For best results, heat the syringe a minimum of 30 minutes at 110°C (230°F) before using. • Apply adequate amount of adhesive to one of the substrates to be bonded. Join the substrates within the adhesive’s specified open time and hold the bonded part until the adhesive has adequately set. Note: When using solvents, extinguish all ignition sources, and follow the manufacturer’s precautions and directions for use. Detailed Images

Disassembly process While heating, applying external force is the effective method of heavy Industry 1. For bonding the LCD module and the border, heated for 5 to 15 minutes @65-80 ℃, while applying for 5-10 kg force (thrust and pressure), so it is easy to separate parts 2. Clean with mild solvent to wipe off the residue glue on the LCD module (such as isopropyl alcohol, n-heptane, etc.), avoid solvent into the LCD module to cause damage 3. Suitable heavy industry system will greatly improve efficiency 4. It is better to test LCD module whether also can work normally after the heating, to modify the heating temperature and external force size according to it. Typical Application Typical Application High performance for lens/case and housing assembly in cell phones and notebooks, MP3 players, portable batteries, and other consumer electronics • Thin, tough and flexible bond lines help improve fit, appearance,and reliability. • Excellent high strength bonds for plastics and metals, dissimilar substrates, and even hard-to-bond plastics such as polycarbonate. • No whitening, as often occurs with cyanoacrylate adhesives on plastic. • No plastic cracking, as may occur with ultrasonic welding Handling/Application Information Directions for Use Apply to clean, dried surfaces. Remove oil, grease and other contaminants by wiping with isopropyl alcohol. For materials that are often contaminated with mold release agents, it is recommended that the surface be solvent wiped, abraded and solvent wiped. For additional information on surface preparation, see section on Surface Preparation. • For best results, heat the syringe a minimum of 30 minutes at 110°C (230°F) before using. • Apply adequate amount of adhesive to one of the substrates to be bonded. Join the substrates within the adhesive’s specified open time and hold the bonded part until the adhesive has adequately set. Note: When using solvents, extinguish all ignition sources, and follow the manufacturer’s precautions and directions for use. Detailed Images

Packaging & Shipping For PUR hot melt adhesive,our packing is 30ML/PC,2pcs/bag,120pcs /carton .and we can do the packing as your requirements and designs . Our Service Why choose us ? 1. Professional manufacturer & long history We are direct manufacturer of glue and adhesive since 1998.So We have Professional production team, production line, experienced technical experts also much experiences and higher skills to ensuring product quality and deliver in time with a very short time . 2. Competitive quality &factory price 3. Our market Our customer all over the world . Main market in Europe ,South America,Australia and Asia ,such as Vietnam,Thailand , Malaysia and so on . We gained good reputation in the industry because our various items made of imported raw material, good workmanship and fast delivery time. 4. Custom design welcome Customer logo /design/OEM welcome .So our products always so creative&innovative . 5. Best service We keep every customer for long time business.We regard every one as our VIP,no matter small or big order .

Packaging & Shipping For PUR hot melt adhesive,our packing is 30ML/PC,2pcs/bag,120pcs /carton .and we can do the packing as your requirements and designs . Our Service Why choose us ? 1. Professional manufacturer & long history We are direct manufacturer of glue and adhesive since 1998.So We have Professional production team, production line, experienced technical experts also much experiences and higher skills to ensuring product quality and deliver in time with a very short time . 2. Competitive quality &factory price 3. Our market Our customer all over the world . Main market in Europe ,South America,Australia and Asia ,such as Vietnam,Thailand , Malaysia and so on . We gained good reputation in the industry because our various items made of imported raw material, good workmanship and fast delivery time. 4. Custom design welcome Customer logo /design/OEM welcome .So our products always so creative&innovative . 5. Best service We keep every customer for long time business.We regard every one as our VIP,no matter small or big order .