Epoxy Resin for Making Led Channel Letters

- Delivery Time:

- 1 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Product Description MTB-4402 Crystal Epoxy Resin and Hardener for Doming ,Coating and Potting on Making LED Channel Letters  Instruction MTB-4402 Hard ard crystal epoxy AB resin,made from the basic pure resin, defoamer, flow ping agent, thinner and additives by fine processing . Can be cured both with room temperature and by heating. Clear, low viscosity and easy to defoam ,forming automatic foam, automatic levelling, after curing, no bubble. With good diaphaneity, excellent surface gloss. High transparency and good performance after mixed Good UV and yellow resistance The clearance can be five years with appropriate proportion. With some hardness and toughness after cured, good flatness, high glossy effect, no bubbles after mixed High adhesive strength, excellent solvent and wound resistance Can mix with the pigments with different colors, then apply on the LED channel letters Application Good for making LED channel letters Excellent for potting and sealing on panel of solar batter, LED lights, and other crafts. Especially suitable for the dome of photos, photo album ,keyring,mobile phone shell,nameplate,badge,jewellry box,photo frame,nail scissors and so on. Suitable for adhesive, PVC film, plastic, glass, metal trademark surface glue. For the epoxy of magnetic stick, mobile post, tattoo paste, wine mark. Applied for electronic components such as LED perforation lamp, crystal handicraft’s transparent packaging Appearance &Character

Instruction MTB-4402 Hard ard crystal epoxy AB resin,made from the basic pure resin, defoamer, flow ping agent, thinner and additives by fine processing . Can be cured both with room temperature and by heating. Clear, low viscosity and easy to defoam ,forming automatic foam, automatic levelling, after curing, no bubble. With good diaphaneity, excellent surface gloss. High transparency and good performance after mixed Good UV and yellow resistance The clearance can be five years with appropriate proportion. With some hardness and toughness after cured, good flatness, high glossy effect, no bubbles after mixed High adhesive strength, excellent solvent and wound resistance Can mix with the pigments with different colors, then apply on the LED channel letters Application Good for making LED channel letters Excellent for potting and sealing on panel of solar batter, LED lights, and other crafts. Especially suitable for the dome of photos, photo album ,keyring,mobile phone shell,nameplate,badge,jewellry box,photo frame,nail scissors and so on. Suitable for adhesive, PVC film, plastic, glass, metal trademark surface glue. For the epoxy of magnetic stick, mobile post, tattoo paste, wine mark. Applied for electronic components such as LED perforation lamp, crystal handicraft’s transparent packaging Appearance &Character

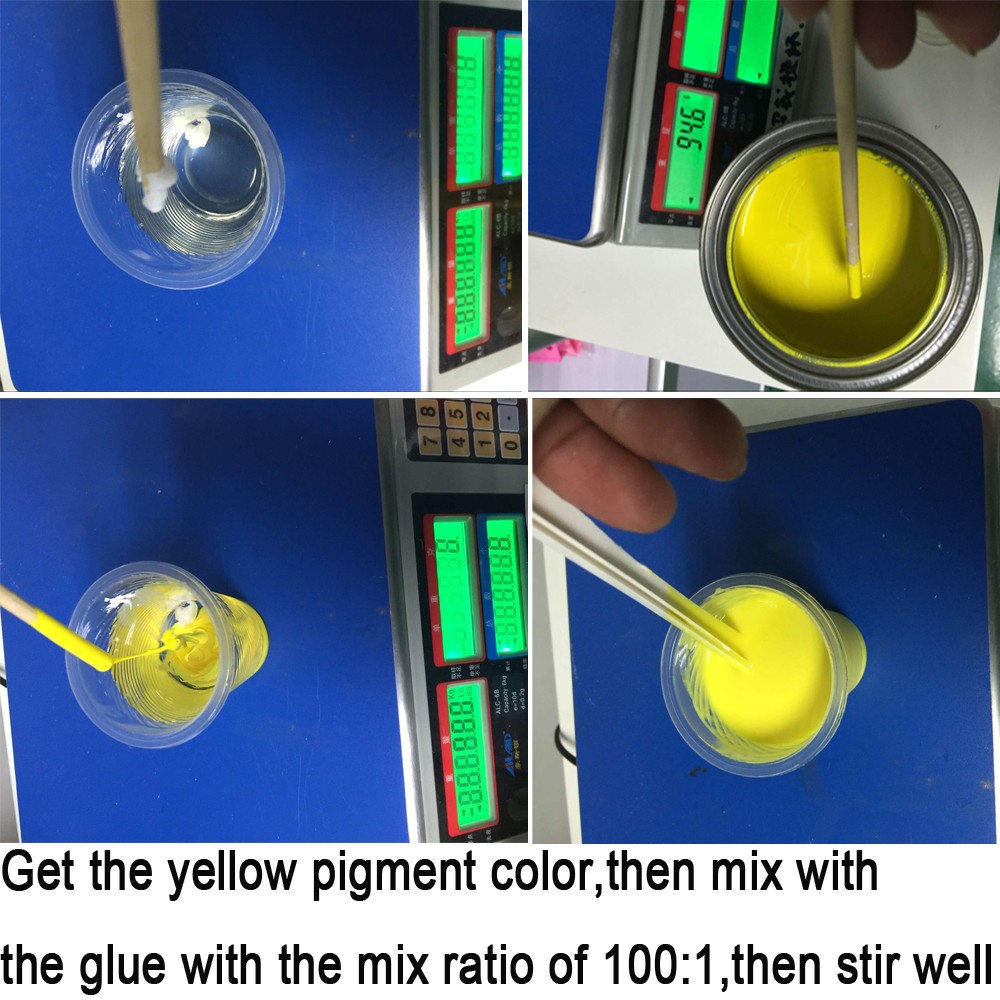

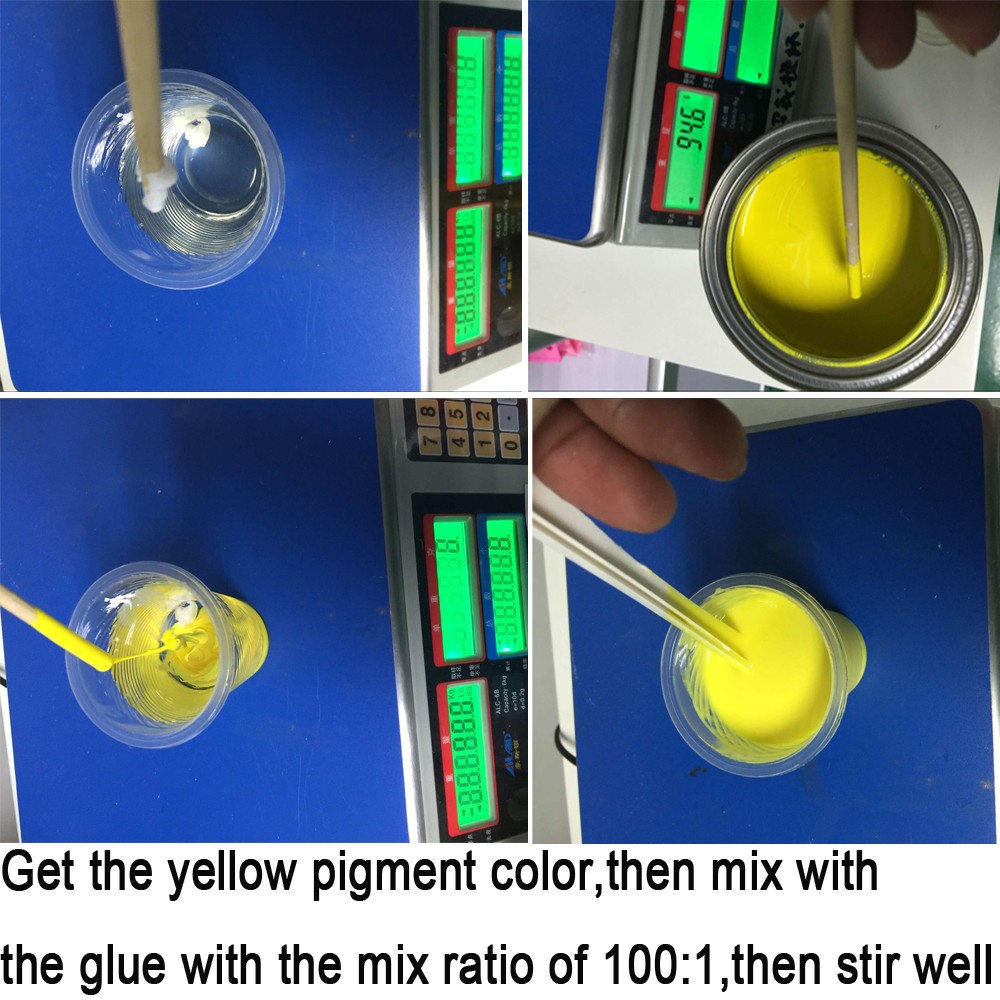

Operation Steps--Take Yellow colors for example Step 1--Prepare all of the materials you need,MTB-4402 epoxy resin AB glue ,color pigment of yellow (or any colors you like ),and white color ,it is essential.  Step 2--Mix MTB-4402 Epoxy resin and Color Pigment

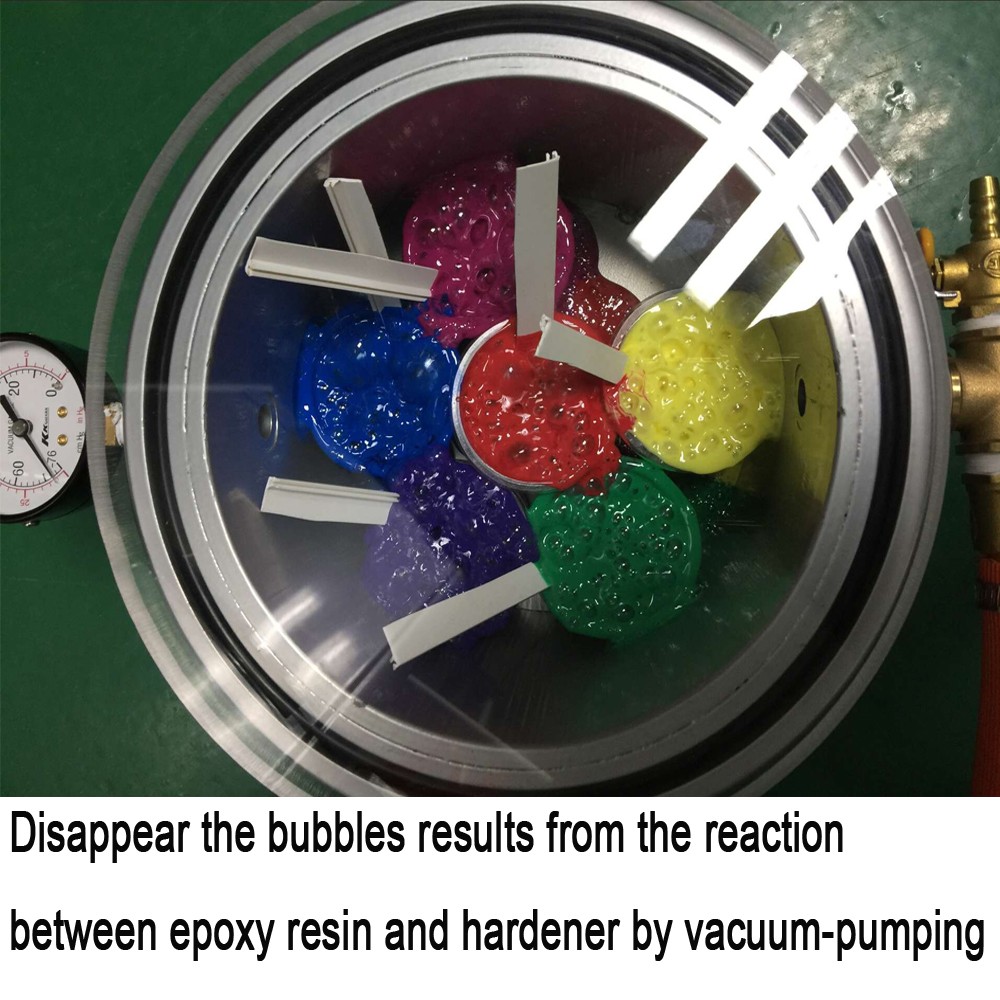

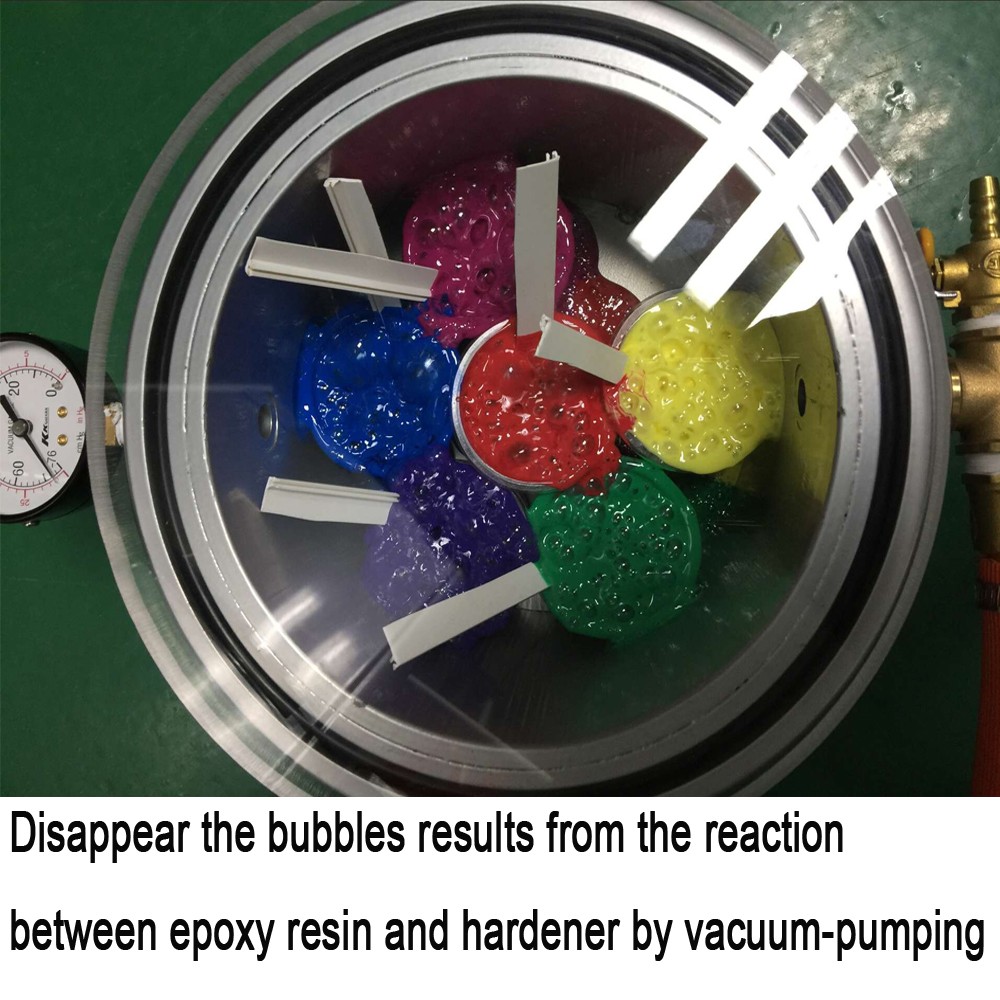

Step 2--Mix MTB-4402 Epoxy resin and Color Pigment  Step 3-Vacuum the Bubbles that get during the reaction of mixing epoxy resin and hardener

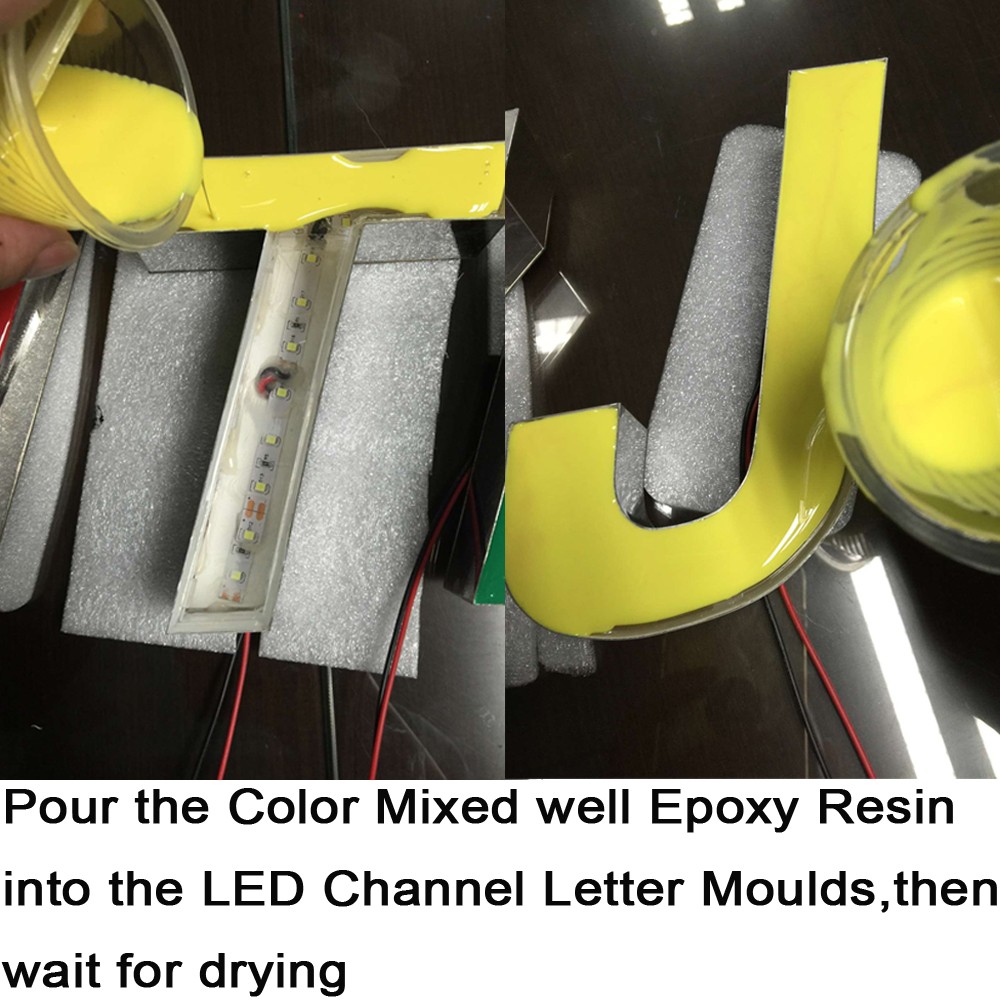

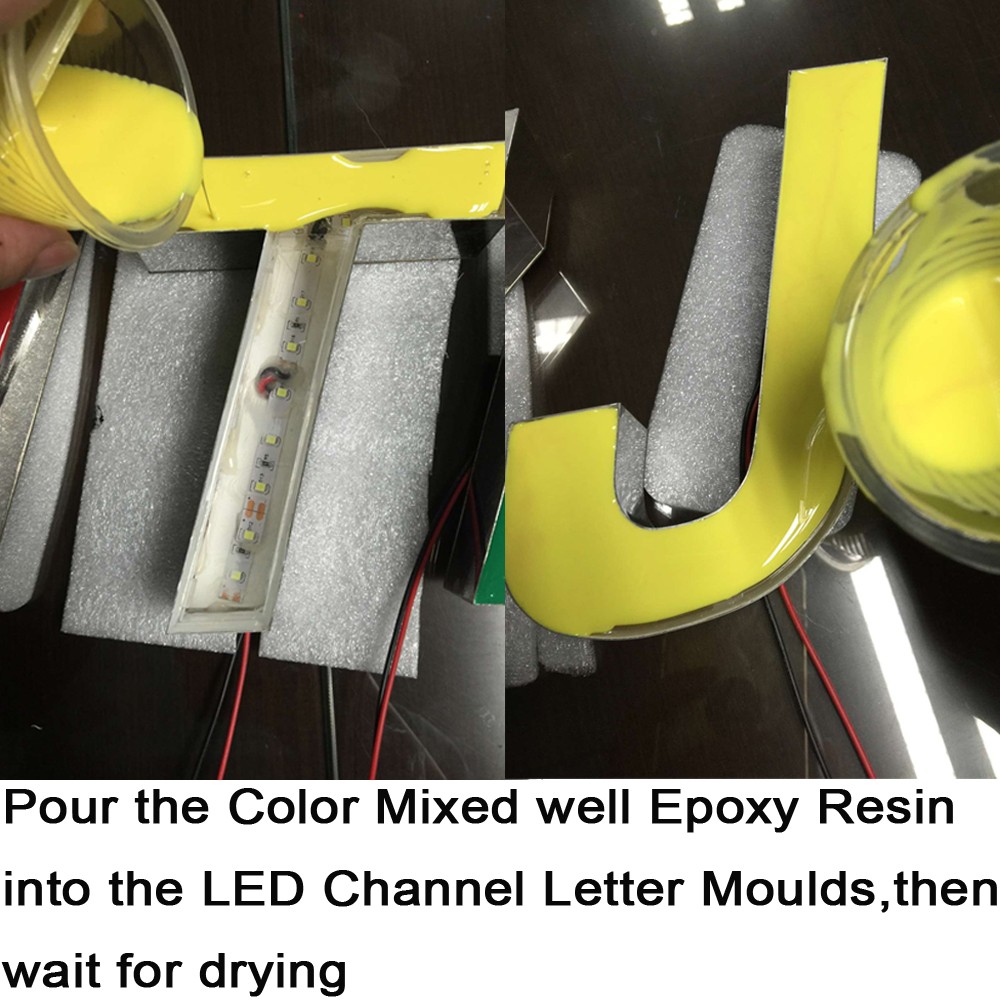

Step 3-Vacuum the Bubbles that get during the reaction of mixing epoxy resin and hardener  Step 4---Apply the Mixed well MTB-4402 Epoxy Resin and Color Pigment into the LED Channel Letters Moulds

Step 4---Apply the Mixed well MTB-4402 Epoxy Resin and Color Pigment into the LED Channel Letters Moulds  Step 5-Finished LED Channel Letters in the day and in the night

Step 5-Finished LED Channel Letters in the day and in the night

Packages It is 5kgs/barrel,15kgs/set, epoxy resin( A) of 10kgs and hardener(B)of 5kgs,15kgs/set,20kgs/carton.And we can do the package as your designs. Notes This product will begin to cure after mixing, the viscosity will gradually rise, andpart of heat will release. The more the amount of rubber mixing, the faster the reaction, the curing speed will be faster, and may be let out a lot of heat, please pay attention to control a match the amount of adhesive, because the reaction is accelerated, it can use will shorten the time, after mixing the glue solution in a short period of time used up as far as possible Use time refers to under the condition of 25 ℃, 100 g glue mixture liquid of viscosity double time, not operational time, adhesive solution should never be used There are very few people contact adhesive solution for a long time will producemild skin irritation, mild itch, suggest to wear protective gloves when using, please with skin with acetone or alcohol wipe, and use cleaner clean Before using, please first small trial, master is a use of the products, so as to avoid mistakes and waste. Company Information About us 1. We are direct manufacturer of glue and adhesive since 1998. 2. Main articles we sell well are clear epoxy resin AB glue ,two components metal structural adhesive ,instant glue ,anaerobic adhesive ,N-times removable sticky notes glue ,glue dots ,UV glue ,OCA adhesive ,UV nail gel ,retaining compound Adhesive,hot melt adhesive ,PVC-ABS plastic glue ,magic stickers,no nail and mark wall hook,sticky screen cleaner ,mobile phone stickers and so on 3.The certificates we have gained are Patent of Removable Glue Dots ,SGS ,MSDS ,EC ,ROHS . 4.The factory audit we pass are SGS and Walmart audit.

Packages It is 5kgs/barrel,15kgs/set, epoxy resin( A) of 10kgs and hardener(B)of 5kgs,15kgs/set,20kgs/carton.And we can do the package as your designs. Notes This product will begin to cure after mixing, the viscosity will gradually rise, andpart of heat will release. The more the amount of rubber mixing, the faster the reaction, the curing speed will be faster, and may be let out a lot of heat, please pay attention to control a match the amount of adhesive, because the reaction is accelerated, it can use will shorten the time, after mixing the glue solution in a short period of time used up as far as possible Use time refers to under the condition of 25 ℃, 100 g glue mixture liquid of viscosity double time, not operational time, adhesive solution should never be used There are very few people contact adhesive solution for a long time will producemild skin irritation, mild itch, suggest to wear protective gloves when using, please with skin with acetone or alcohol wipe, and use cleaner clean Before using, please first small trial, master is a use of the products, so as to avoid mistakes and waste. Company Information About us 1. We are direct manufacturer of glue and adhesive since 1998. 2. Main articles we sell well are clear epoxy resin AB glue ,two components metal structural adhesive ,instant glue ,anaerobic adhesive ,N-times removable sticky notes glue ,glue dots ,UV glue ,OCA adhesive ,UV nail gel ,retaining compound Adhesive,hot melt adhesive ,PVC-ABS plastic glue ,magic stickers,no nail and mark wall hook,sticky screen cleaner ,mobile phone stickers and so on 3.The certificates we have gained are Patent of Removable Glue Dots ,SGS ,MSDS ,EC ,ROHS . 4.The factory audit we pass are SGS and Walmart audit.

Instruction MTB-4402 Hard ard crystal epoxy AB resin,made from the basic pure resin, defoamer, flow ping agent, thinner and additives by fine processing . Can be cured both with room temperature and by heating. Clear, low viscosity and easy to defoam ,forming automatic foam, automatic levelling, after curing, no bubble. With good diaphaneity, excellent surface gloss. High transparency and good performance after mixed Good UV and yellow resistance The clearance can be five years with appropriate proportion. With some hardness and toughness after cured, good flatness, high glossy effect, no bubbles after mixed High adhesive strength, excellent solvent and wound resistance Can mix with the pigments with different colors, then apply on the LED channel letters Application Good for making LED channel letters Excellent for potting and sealing on panel of solar batter, LED lights, and other crafts. Especially suitable for the dome of photos, photo album ,keyring,mobile phone shell,nameplate,badge,jewellry box,photo frame,nail scissors and so on. Suitable for adhesive, PVC film, plastic, glass, metal trademark surface glue. For the epoxy of magnetic stick, mobile post, tattoo paste, wine mark. Applied for electronic components such as LED perforation lamp, crystal handicraft’s transparent packaging Appearance &Character

Instruction MTB-4402 Hard ard crystal epoxy AB resin,made from the basic pure resin, defoamer, flow ping agent, thinner and additives by fine processing . Can be cured both with room temperature and by heating. Clear, low viscosity and easy to defoam ,forming automatic foam, automatic levelling, after curing, no bubble. With good diaphaneity, excellent surface gloss. High transparency and good performance after mixed Good UV and yellow resistance The clearance can be five years with appropriate proportion. With some hardness and toughness after cured, good flatness, high glossy effect, no bubbles after mixed High adhesive strength, excellent solvent and wound resistance Can mix with the pigments with different colors, then apply on the LED channel letters Application Good for making LED channel letters Excellent for potting and sealing on panel of solar batter, LED lights, and other crafts. Especially suitable for the dome of photos, photo album ,keyring,mobile phone shell,nameplate,badge,jewellry box,photo frame,nail scissors and so on. Suitable for adhesive, PVC film, plastic, glass, metal trademark surface glue. For the epoxy of magnetic stick, mobile post, tattoo paste, wine mark. Applied for electronic components such as LED perforation lamp, crystal handicraft’s transparent packaging Appearance &Character Item | MTB-4402 Epoxy Resin(A) | MTB-4402 Hardener (B) |

Color | Transparent Liquid | Transparent Liquid |

Specific Gravity @25℃, g/cubic centemeters | 1.19 | 1.08 |

Viscosity@25℃ | 1600-2600cps | 320-500cps |

Mix Ratio (by weight) | 2 | 1 |

Operation Time(100g, @25℃) | 50mins | |

Curing time | 6-8h at room temperature ;1.5h @60℃ | |

Shelf Life | 6-12m(cool and dry place under 25℃ ) | |

Step 2--Mix MTB-4402 Epoxy resin and Color Pigment

Step 2--Mix MTB-4402 Epoxy resin and Color Pigment  Step 3-Vacuum the Bubbles that get during the reaction of mixing epoxy resin and hardener

Step 3-Vacuum the Bubbles that get during the reaction of mixing epoxy resin and hardener  Step 4---Apply the Mixed well MTB-4402 Epoxy Resin and Color Pigment into the LED Channel Letters Moulds

Step 4---Apply the Mixed well MTB-4402 Epoxy Resin and Color Pigment into the LED Channel Letters Moulds  Step 5-Finished LED Channel Letters in the day and in the night

Step 5-Finished LED Channel Letters in the day and in the night

Packages It is 5kgs/barrel,15kgs/set, epoxy resin( A) of 10kgs and hardener(B)of 5kgs,15kgs/set,20kgs/carton.And we can do the package as your designs. Notes This product will begin to cure after mixing, the viscosity will gradually rise, andpart of heat will release. The more the amount of rubber mixing, the faster the reaction, the curing speed will be faster, and may be let out a lot of heat, please pay attention to control a match the amount of adhesive, because the reaction is accelerated, it can use will shorten the time, after mixing the glue solution in a short period of time used up as far as possible Use time refers to under the condition of 25 ℃, 100 g glue mixture liquid of viscosity double time, not operational time, adhesive solution should never be used There are very few people contact adhesive solution for a long time will producemild skin irritation, mild itch, suggest to wear protective gloves when using, please with skin with acetone or alcohol wipe, and use cleaner clean Before using, please first small trial, master is a use of the products, so as to avoid mistakes and waste. Company Information About us 1. We are direct manufacturer of glue and adhesive since 1998. 2. Main articles we sell well are clear epoxy resin AB glue ,two components metal structural adhesive ,instant glue ,anaerobic adhesive ,N-times removable sticky notes glue ,glue dots ,UV glue ,OCA adhesive ,UV nail gel ,retaining compound Adhesive,hot melt adhesive ,PVC-ABS plastic glue ,magic stickers,no nail and mark wall hook,sticky screen cleaner ,mobile phone stickers and so on 3.The certificates we have gained are Patent of Removable Glue Dots ,SGS ,MSDS ,EC ,ROHS . 4.The factory audit we pass are SGS and Walmart audit.

Packages It is 5kgs/barrel,15kgs/set, epoxy resin( A) of 10kgs and hardener(B)of 5kgs,15kgs/set,20kgs/carton.And we can do the package as your designs. Notes This product will begin to cure after mixing, the viscosity will gradually rise, andpart of heat will release. The more the amount of rubber mixing, the faster the reaction, the curing speed will be faster, and may be let out a lot of heat, please pay attention to control a match the amount of adhesive, because the reaction is accelerated, it can use will shorten the time, after mixing the glue solution in a short period of time used up as far as possible Use time refers to under the condition of 25 ℃, 100 g glue mixture liquid of viscosity double time, not operational time, adhesive solution should never be used There are very few people contact adhesive solution for a long time will producemild skin irritation, mild itch, suggest to wear protective gloves when using, please with skin with acetone or alcohol wipe, and use cleaner clean Before using, please first small trial, master is a use of the products, so as to avoid mistakes and waste. Company Information About us 1. We are direct manufacturer of glue and adhesive since 1998. 2. Main articles we sell well are clear epoxy resin AB glue ,two components metal structural adhesive ,instant glue ,anaerobic adhesive ,N-times removable sticky notes glue ,glue dots ,UV glue ,OCA adhesive ,UV nail gel ,retaining compound Adhesive,hot melt adhesive ,PVC-ABS plastic glue ,magic stickers,no nail and mark wall hook,sticky screen cleaner ,mobile phone stickers and so on 3.The certificates we have gained are Patent of Removable Glue Dots ,SGS ,MSDS ,EC ,ROHS . 4.The factory audit we pass are SGS and Walmart audit.