High Quality Permeable Resin Bound Paving

- Delivery Time:

- 1 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

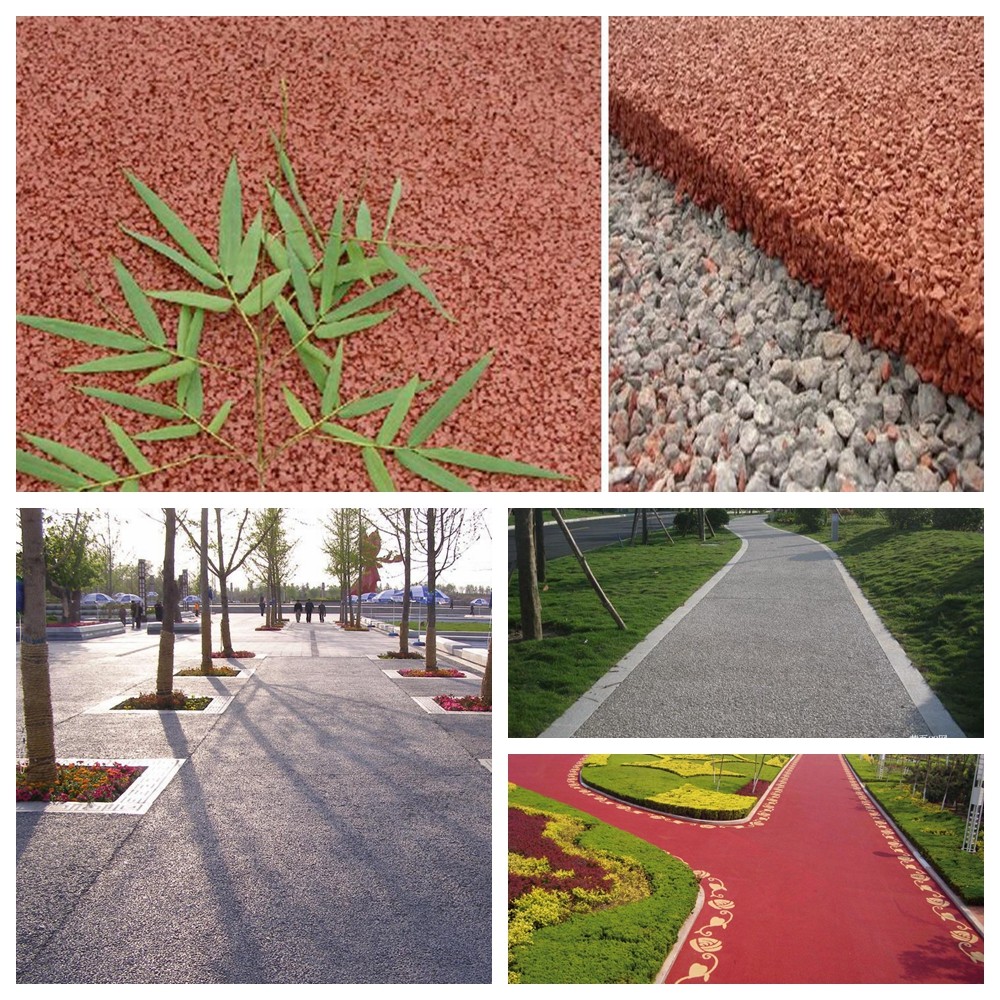

Product Description  MTB-7910 Epoxy Resin and Hardener for Paving Features Transparent and low ordor

MTB-7910 Epoxy Resin and Hardener for Paving Features Transparent and low ordor

Excellent bonding strength

High harness

Good waterproof,excellet heat and chemical resistance

Can mix any aggregates such as stones,gravels,pebbles,sands,quartz and so on.

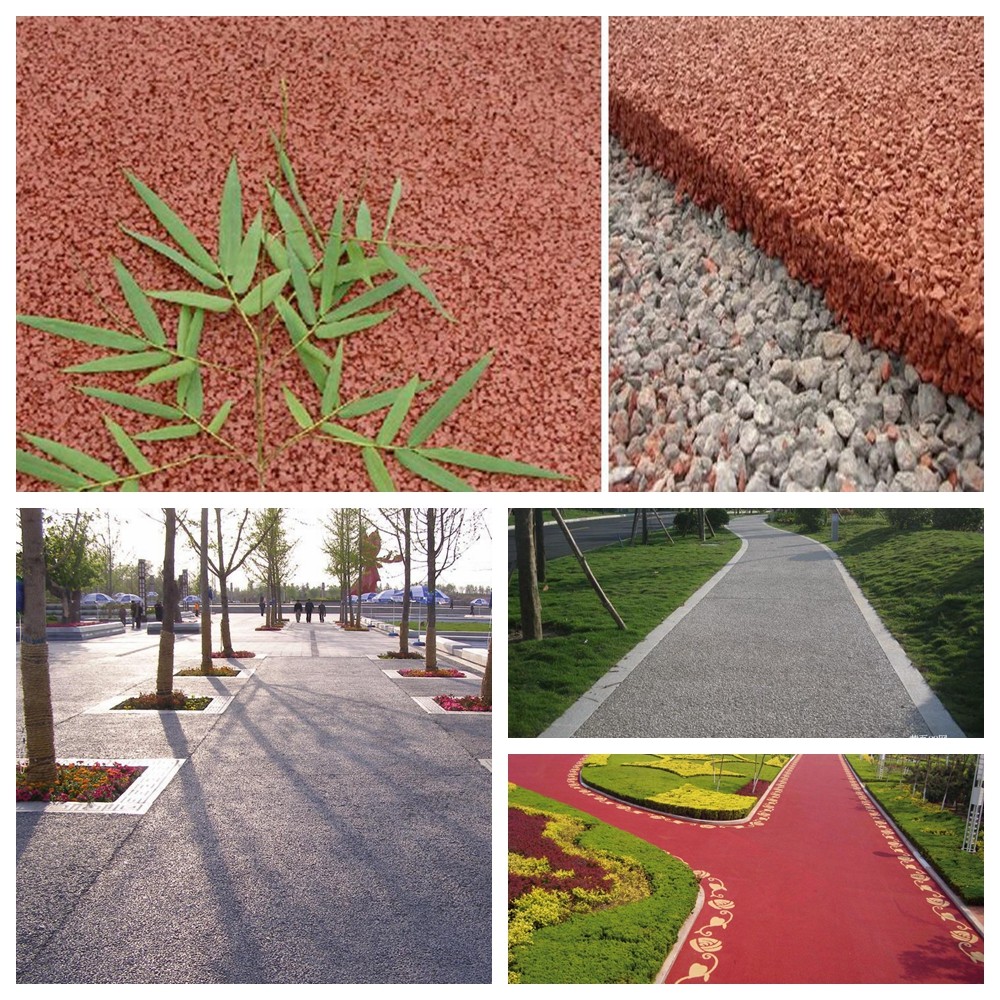

Excellent water permeability for the finished paving.

Finished Resin Bonded Paving Features 38% of resin formulated from a botanic source

UV stable non yellowing resin,good water ,oil,acid ,heat,cold resistance

Product warranty up to 15 years available

Natural appearance

Recycled aggregates available

Highly permeable—up to 850 litres / m² / minute

High slip resistance

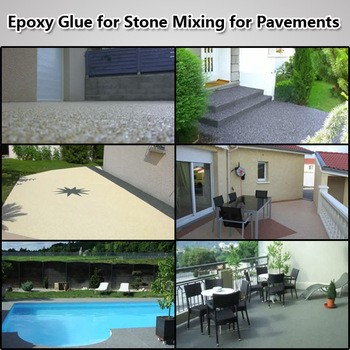

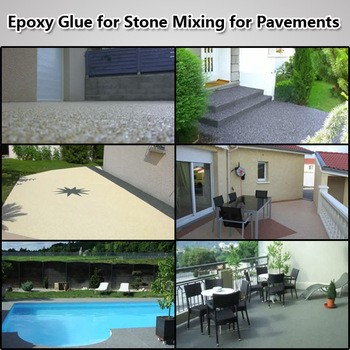

Suitable for pool surrounds,pathways,floor,garden, driveways, car parks and access roads and so on

Low maintenance

Variety of colours

With peration time of 2hrs

Can bear the light vehichles ,like SUV ,cars,bikes and so on Application Good the base decoration for car parks suitable for cars & light delivery;paving for pedestrian and vehicle traffic,

footpaths,driveways,walkingways,tree patios and so on.Main apply on Tourist area,square,park,hotel,villa,

leisure place,coffee shop,bar,hotel,shop,office,interior and outdoor decoration of house and so on.

Residential Paving Pathways Footpath Garden Paving and pathway Tree Pit Indoor Flooring Patio Paving Driveways Commercial Paving Pool Surrounds Hard Landscaping Public footways and private pathways Paving For Housing Access Road Surfaces Car Park Paving Leisure Paving School Paving

Technical Data Sheet

Technical Data Sheet

Coverage Data Coverage Data

MTBJZJ Resin Bound Surfacing Resin 1.5kgs (Epoxy Resin (A)+Hardener(B))

MTBJZJResin Bound Surfacing Aggregate(4~6mm) 100kgs

Coverage @ 10mm 6.5m² (approx)

Coverage @ 15mm 4.675m² (approx)

Coverage @ 18mm 3.89m² (approx)

Coverage @ 20mm 3.5m² (approx) Physical Properties Physical Properties of MTBJZJ resin @ 20-25°C

Working Time 40—55 minutes

Lay Before Rain 4—4½ hours

Foot traffic after 1 3—14½ hours

Light vehicle traffic after 1½—2 days

Occasional heavy vehicle traffic after 7 days

Notes:Site conditions will affect the times quoted. All data is provided as a guide only.

Instructions for Use Instructions for Use

1.New asphalt concrete should be left to cool and gain strength for not less than 24 hours @ 20ºC

2.The surface of the asphalt concrete must be clean, dry and free from loose materials.

3.Ensure that the mixing station is fully waterproof when rain is expected,discontinue mixing when fog or mist are anticipated. Light rain on the surface of the system is unlikely to damage or affect the surface, see later reference to application in rainy conditions.

4.Place MTBJZJ Resin Bound Surfacing Aggregate into a clean, dry, forced action mixer minimum capacity/ power 120 litres/ 1.8kW, Baron E200 mixer or similar.

5.Scrape all of the contents of MTBJZJ Resin Bound Surfacing B component into the larger A component container and mix with a drill and helical paddle mixer attachment for 30-45 seconds. Keep mixing time to a minimum to avoid a build up of heat.

6.Immediately add the mixed resin to the aggregate in the mixer. Mix the aggregate and resin together until all the aggregate is evenly coated with resin. Keep mixing time to a minimum to avoid a build up of heat.

7.Discharge the mixed resin and aggregate onto the prepared surface, level and smooth. Excessive compaction will reduce permeability.

8.Finish the surface with a suitable float.

9.If required, immediately cast MTBJZJ Resin Bound Surfacing Anti-Slip Aggregate onto the top surface of the wet resin and aggregate, at the rate of approximately 0.1kg/m². Ensure even coverage to prevent a patchy appearance.

Allow to cure and open to traffic as described in Physical Properties.

Working Temperatures

Working time is affected by temperature; at temperatures above 25°C the pot life and working time may be insufficient to allow its proper application. Work should therefore not proceed when product and / or air temperature exceeds 25°C. The air temperature must therefore be monitored during application and work should stop when temperature is above 25°C. Care must be taken to keep materials as cool as possible in warm weather.

Rain During Application

Light rain on the surface of the system is unlikely to cause damage to or affect the surface. Heavy rain is likely to spoil the appearance of the surface. Very heavy rain could wash out resin and aggregate. Therefore application during rain or when rain is anticipated during the cure period is not recommended (see Physical Properties). Care must be taken to keep the mixing station dry, thus avoiding entrapment of moisture between aggregate and resin.

Detail Images

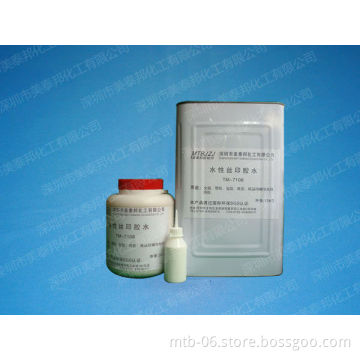

Package & Delivery Title goes here. 5KGS/barrel ,15kgs/set (10kgs of epoxy resin in white bottle and 5kgs of hardener in blue bottle ),and we accept OEM&ODM.

Package & Delivery Title goes here. 5KGS/barrel ,15kgs/set (10kgs of epoxy resin in white bottle and 5kgs of hardener in blue bottle ),and we accept OEM&ODM.

MTB-7910 Epoxy Resin and Hardener for Paving Features Transparent and low ordor

MTB-7910 Epoxy Resin and Hardener for Paving Features Transparent and low ordor Excellent bonding strength

High harness

Good waterproof,excellet heat and chemical resistance

Can mix any aggregates such as stones,gravels,pebbles,sands,quartz and so on.

Excellent water permeability for the finished paving.

Finished Resin Bonded Paving Features 38% of resin formulated from a botanic source

UV stable non yellowing resin,good water ,oil,acid ,heat,cold resistance

Product warranty up to 15 years available

Natural appearance

Recycled aggregates available

Highly permeable—up to 850 litres / m² / minute

High slip resistance

Suitable for pool surrounds,pathways,floor,garden, driveways, car parks and access roads and so on

Low maintenance

Variety of colours

With peration time of 2hrs

Can bear the light vehichles ,like SUV ,cars,bikes and so on Application Good the base decoration for car parks suitable for cars & light delivery;paving for pedestrian and vehicle traffic,

footpaths,driveways,walkingways,tree patios and so on.Main apply on Tourist area,square,park,hotel,villa,

leisure place,coffee shop,bar,hotel,shop,office,interior and outdoor decoration of house and so on.

Residential Paving Pathways Footpath Garden Paving and pathway Tree Pit Indoor Flooring Patio Paving Driveways Commercial Paving Pool Surrounds Hard Landscaping Public footways and private pathways Paving For Housing Access Road Surfaces Car Park Paving Leisure Paving School Paving

Technical Data Sheet

Technical Data Sheet MTBJZJ Resin Bound Surfacing Resin 1.5kgs (Epoxy Resin (A)+Hardener(B))

MTBJZJResin Bound Surfacing Aggregate(4~6mm) 100kgs

Coverage @ 10mm 6.5m² (approx)

Coverage @ 15mm 4.675m² (approx)

Coverage @ 18mm 3.89m² (approx)

Coverage @ 20mm 3.5m² (approx) Physical Properties Physical Properties of MTBJZJ resin @ 20-25°C

Working Time 40—55 minutes

Lay Before Rain 4—4½ hours

Foot traffic after 1 3—14½ hours

Light vehicle traffic after 1½—2 days

Occasional heavy vehicle traffic after 7 days

Notes:Site conditions will affect the times quoted. All data is provided as a guide only.

Instructions for Use Instructions for Use

1.New asphalt concrete should be left to cool and gain strength for not less than 24 hours @ 20ºC

2.The surface of the asphalt concrete must be clean, dry and free from loose materials.

3.Ensure that the mixing station is fully waterproof when rain is expected,discontinue mixing when fog or mist are anticipated. Light rain on the surface of the system is unlikely to damage or affect the surface, see later reference to application in rainy conditions.

4.Place MTBJZJ Resin Bound Surfacing Aggregate into a clean, dry, forced action mixer minimum capacity/ power 120 litres/ 1.8kW, Baron E200 mixer or similar.

5.Scrape all of the contents of MTBJZJ Resin Bound Surfacing B component into the larger A component container and mix with a drill and helical paddle mixer attachment for 30-45 seconds. Keep mixing time to a minimum to avoid a build up of heat.

6.Immediately add the mixed resin to the aggregate in the mixer. Mix the aggregate and resin together until all the aggregate is evenly coated with resin. Keep mixing time to a minimum to avoid a build up of heat.

7.Discharge the mixed resin and aggregate onto the prepared surface, level and smooth. Excessive compaction will reduce permeability.

8.Finish the surface with a suitable float.

9.If required, immediately cast MTBJZJ Resin Bound Surfacing Anti-Slip Aggregate onto the top surface of the wet resin and aggregate, at the rate of approximately 0.1kg/m². Ensure even coverage to prevent a patchy appearance.

Allow to cure and open to traffic as described in Physical Properties.

Working Temperatures

Working time is affected by temperature; at temperatures above 25°C the pot life and working time may be insufficient to allow its proper application. Work should therefore not proceed when product and / or air temperature exceeds 25°C. The air temperature must therefore be monitored during application and work should stop when temperature is above 25°C. Care must be taken to keep materials as cool as possible in warm weather.

Rain During Application

Light rain on the surface of the system is unlikely to cause damage to or affect the surface. Heavy rain is likely to spoil the appearance of the surface. Very heavy rain could wash out resin and aggregate. Therefore application during rain or when rain is anticipated during the cure period is not recommended (see Physical Properties). Care must be taken to keep the mixing station dry, thus avoiding entrapment of moisture between aggregate and resin.

Detail Images

Package & Delivery Title goes here. 5KGS/barrel ,15kgs/set (10kgs of epoxy resin in white bottle and 5kgs of hardener in blue bottle ),and we accept OEM&ODM.

Package & Delivery Title goes here. 5KGS/barrel ,15kgs/set (10kgs of epoxy resin in white bottle and 5kgs of hardener in blue bottle ),and we accept OEM&ODM.

Related Keywords

Related Keywords