4545 SMD Type Ink Curing 385nm 3W UV LED

- Delivery Time:

- 1 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

4545 SMD Type For Curing 385nm 3W UV LED Product Description Main Feartures: · CMH(Ceramic ,Metal, and Hard glass )real inorganic package avoid aging problem · Hermetic package · Dimensions: 4.4x4.4x2.9mm · Long operating lifespan: 2,000 hours · High-reliability · Superior ESD protection · With RoHS Directive-compliant · Angle: 60 degrees (optional) Applications: UV Light Curing Microelectronics industry curing Screen printing curing PCB industry curing Medical equipment curing UV LED Printing -UV Resin, Ink and adhesives curing - Lithography curing -Curing inkjet printing -Label printing curing UV LED coating - UV paint coating curing -Floor curing - Car surface paint curing Liquid Applied Including Resin, Inks, Coatings, Adhesives UV Exposure Machine UV Gel Lamp Currency Scorpion Lamp/UV Mosquito Killer Lamp Product Images

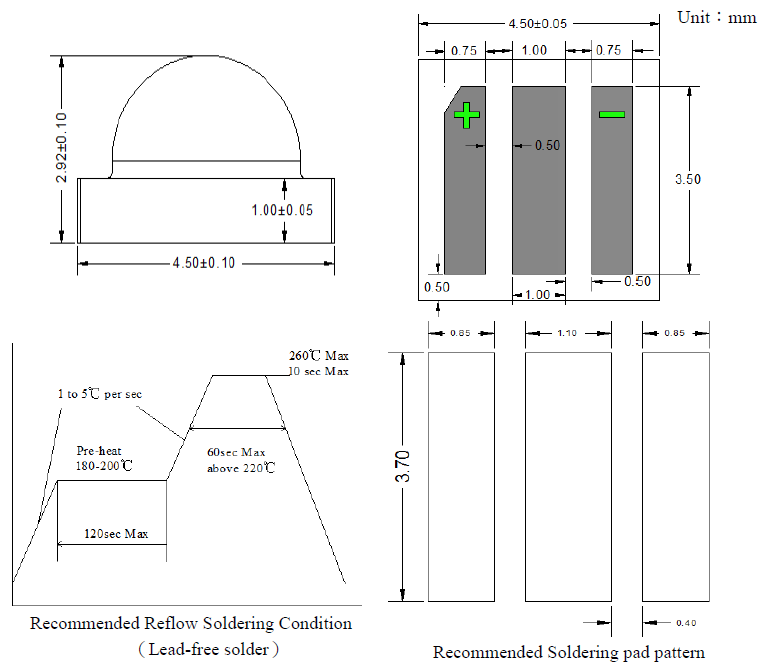

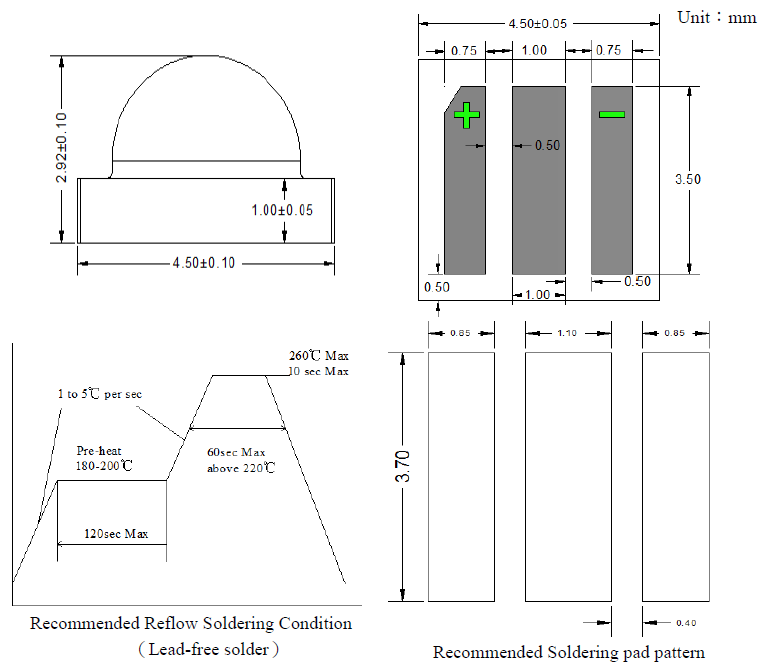

Package Dimensions: Product Thermal Application Information:

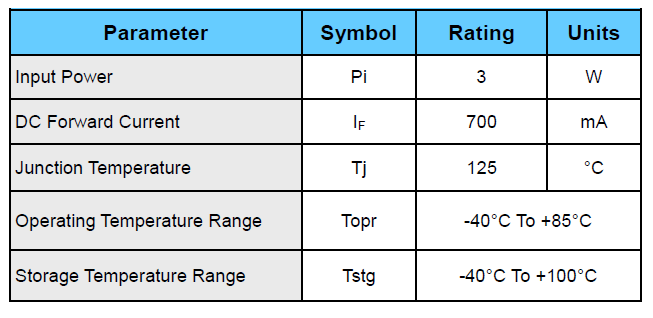

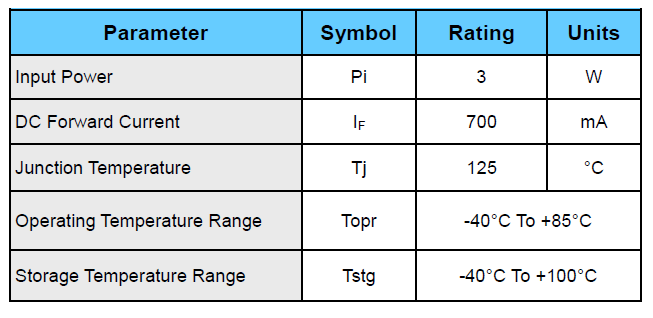

Package Dimensions: Product Thermal Application Information:  Absolute Maximum Ratings at TA=25°C

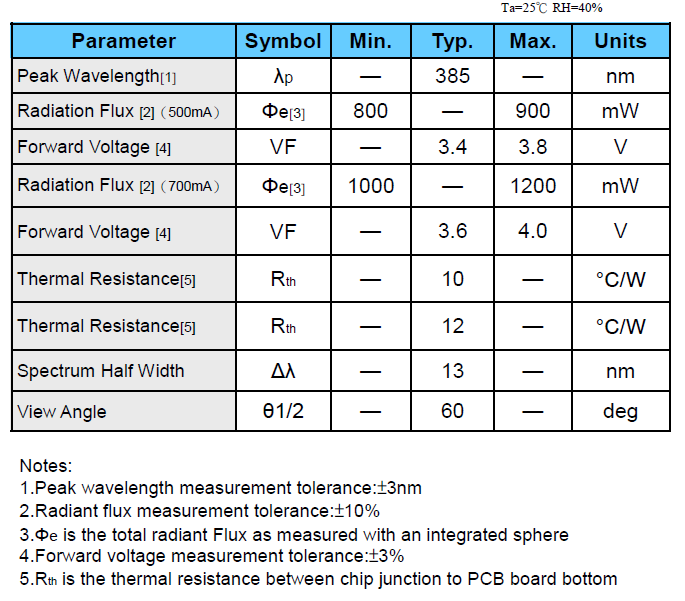

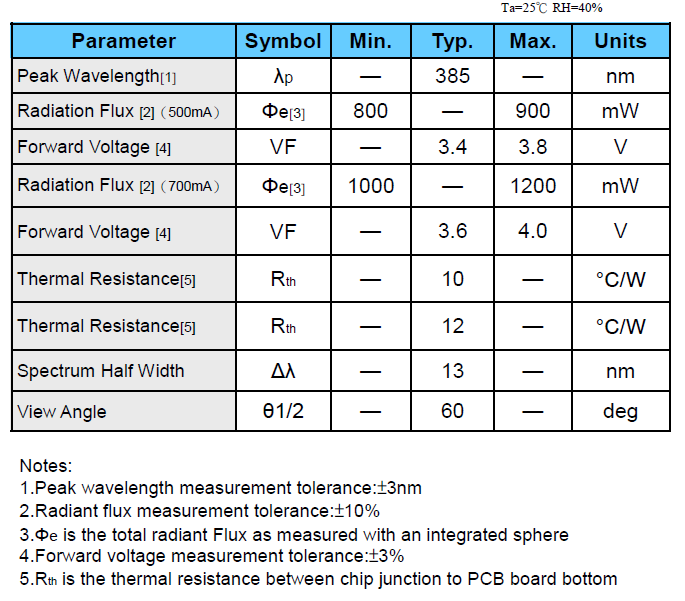

Absolute Maximum Ratings at TA=25°C  Electrical / Optical Characteristics

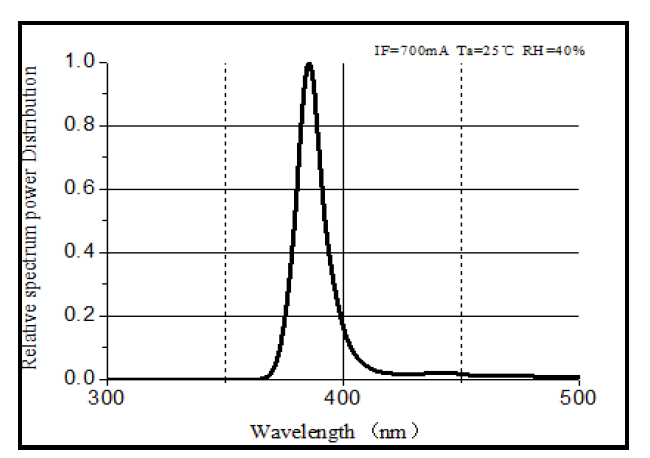

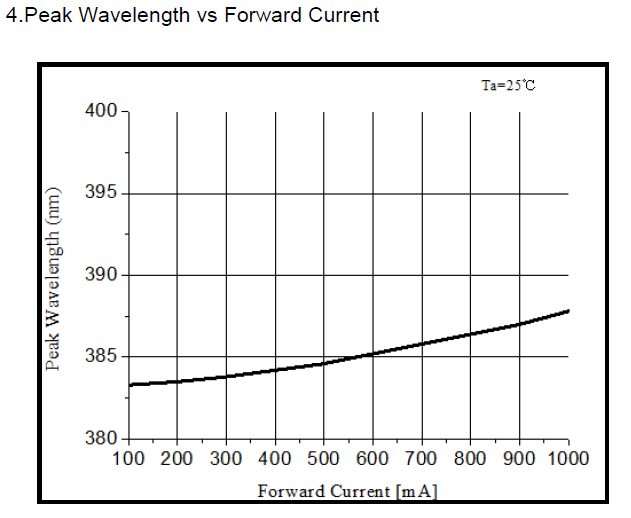

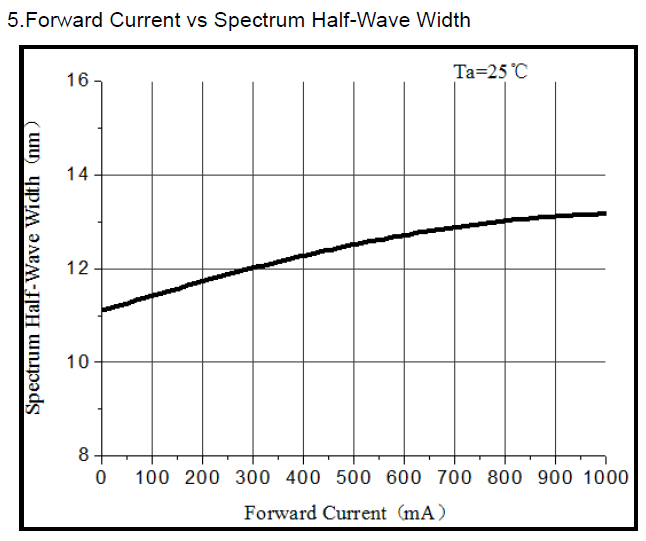

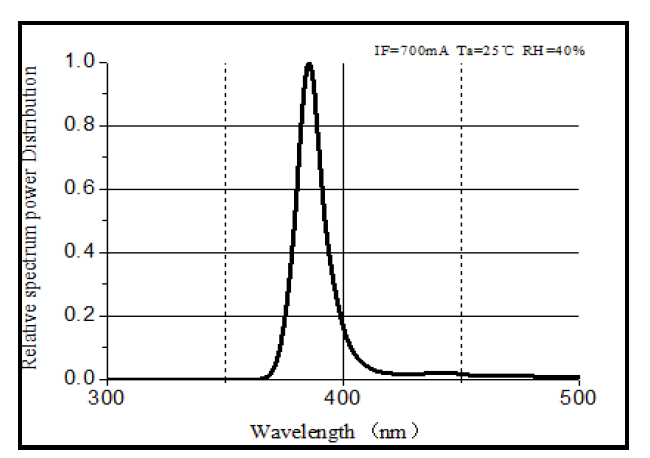

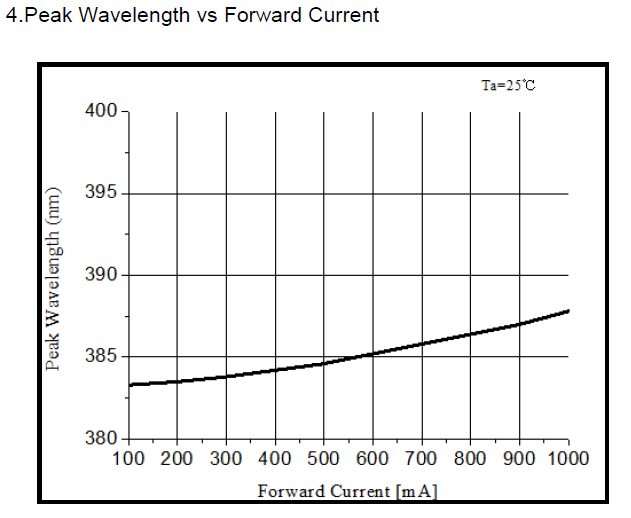

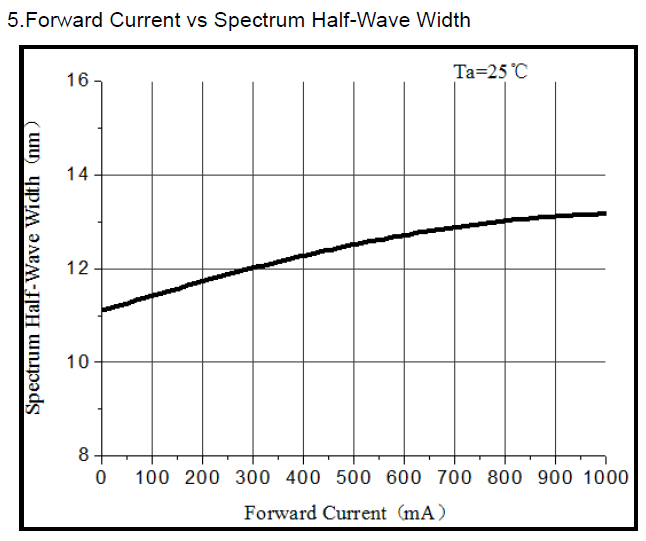

Electrical / Optical Characteristics  Relative Spectrum Power Distribution (700mA)

Relative Spectrum Power Distribution (700mA)  Forward Voltage vs Forward Current

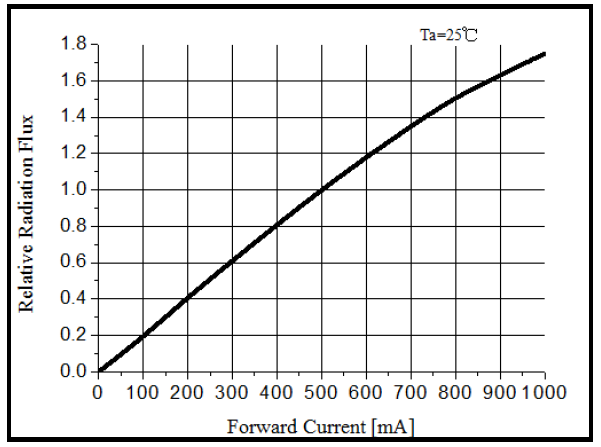

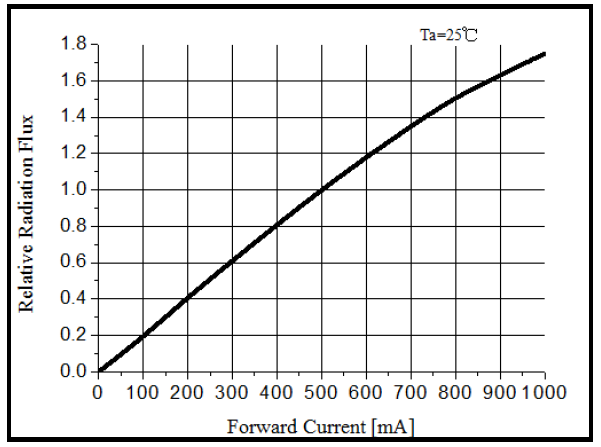

Forward Voltage vs Forward Current  Relative Radiation Flux vs Forward Current

Relative Radiation Flux vs Forward Current

Spatial Distribution Graph Packaging & Shipping Packaging: · Inner packing: anti-static bag · Outer packing: carton box Shipping: 1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

Spatial Distribution Graph Packaging & Shipping Packaging: · Inner packing: anti-static bag · Outer packing: carton box Shipping: 1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 1-2 days for samples; 7-10 days for over batch goods . Our Services We are professional manufactuer of UV LED emiter .R&D team member back from Japan and

Germany. we can provide customized solution for your uv led applicaiton case. CAUTIONS (1) Handling precautions · Do not handle the LEDs with bare hands as it will contaminate the LENS surface and may affect the optical characteristics. · When handling the product with tweezers, be careful not to apply excessive force to glass LENS as it may cause the surface scratch. · Dropping the product may cause damage. (2) Electrostatic Discharge (ESD) · The product are sensitive to static electricity or surge voltage. ESD can damage a die and its reliability. When handling the products, the following measure against electrostatic dis- charge are strongly recommended: Eliminating wrist strap, ESD footwear, clothes, and floors Grounded workstation equipment and tools ESD table/shelf mat made of conductive materials · Ensure that tools, jigs and machines that are being used are properly grounded and that proper grounding techniques are used in work areas. For devices/equipment that mount the LEDs, protection against surge voltages should also be used. · The customer is advised to check if the LEDs are damage by ESD When performing the characteristics inspection of the LEDs in the application. Damage can be detected with a forward voltage measurement at low current(≤1mA). (3) Eye Safety · Please proceed with caution when handling any UVLEDs driven at low or high current. Since UV light can be harmful to eyes, do Not look directly into the UV light, even through an optical instrument. · UV protective glasses are required to use in order to avoid damage by UV light in case of viewing UV light directly. Company Information How to contact us? Send your Inquiry Details in the Below, Click "Send" Now! Free samples are waiting for you.

Package Dimensions: Product Thermal Application Information:

Package Dimensions: Product Thermal Application Information:  Absolute Maximum Ratings at TA=25°C

Absolute Maximum Ratings at TA=25°C  Electrical / Optical Characteristics

Electrical / Optical Characteristics  Relative Spectrum Power Distribution (700mA)

Relative Spectrum Power Distribution (700mA)  Forward Voltage vs Forward Current

Forward Voltage vs Forward Current  Relative Radiation Flux vs Forward Current

Relative Radiation Flux vs Forward Current

Spatial Distribution Graph Packaging & Shipping Packaging: · Inner packing: anti-static bag · Outer packing: carton box Shipping: 1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

Spatial Distribution Graph Packaging & Shipping Packaging: · Inner packing: anti-static bag · Outer packing: carton box Shipping: 1. FedEx/DHL/UPS/TNT for samples, Door-to-Door; 2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 1-2 days for samples; 7-10 days for over batch goods . Our Services We are professional manufactuer of UV LED emiter .R&D team member back from Japan and

Germany. we can provide customized solution for your uv led applicaiton case. CAUTIONS (1) Handling precautions · Do not handle the LEDs with bare hands as it will contaminate the LENS surface and may affect the optical characteristics. · When handling the product with tweezers, be careful not to apply excessive force to glass LENS as it may cause the surface scratch. · Dropping the product may cause damage. (2) Electrostatic Discharge (ESD) · The product are sensitive to static electricity or surge voltage. ESD can damage a die and its reliability. When handling the products, the following measure against electrostatic dis- charge are strongly recommended: Eliminating wrist strap, ESD footwear, clothes, and floors Grounded workstation equipment and tools ESD table/shelf mat made of conductive materials · Ensure that tools, jigs and machines that are being used are properly grounded and that proper grounding techniques are used in work areas. For devices/equipment that mount the LEDs, protection against surge voltages should also be used. · The customer is advised to check if the LEDs are damage by ESD When performing the characteristics inspection of the LEDs in the application. Damage can be detected with a forward voltage measurement at low current(≤1mA). (3) Eye Safety · Please proceed with caution when handling any UVLEDs driven at low or high current. Since UV light can be harmful to eyes, do Not look directly into the UV light, even through an optical instrument. · UV protective glasses are required to use in order to avoid damage by UV light in case of viewing UV light directly. Company Information How to contact us? Send your Inquiry Details in the Below, Click "Send" Now! Free samples are waiting for you.

Related Keywords

Related Keywords

You May Also Like

You May Also Like