High Thermal Conductivity Aluminum pcb

- Delivery Time:

- 14 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Product Description

Our Services 1.PCB Favricate 2. buy components 3.assembly components 4. PCB layout if provide the schematic 5.Copy PCB Board if provide sample 6.Test PCB ,PCBA funcation if provide test method. Product Show  Company Information RayMing Technology Co.,Ltd was founded in 1997, is a high-teach enterprise specializing in the production of high-level,high-precision printed circuit boards. We have more than 10,000 square meters,with more than 500 professional employees,monthly capability is 20,000sqm,5000types.

Company Information RayMing Technology Co.,Ltd was founded in 1997, is a high-teach enterprise specializing in the production of high-level,high-precision printed circuit boards. We have more than 10,000 square meters,with more than 500 professional employees,monthly capability is 20,000sqm,5000types.

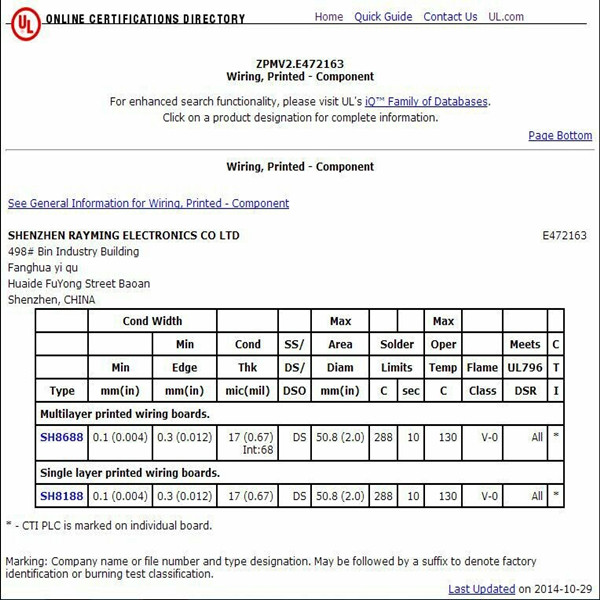

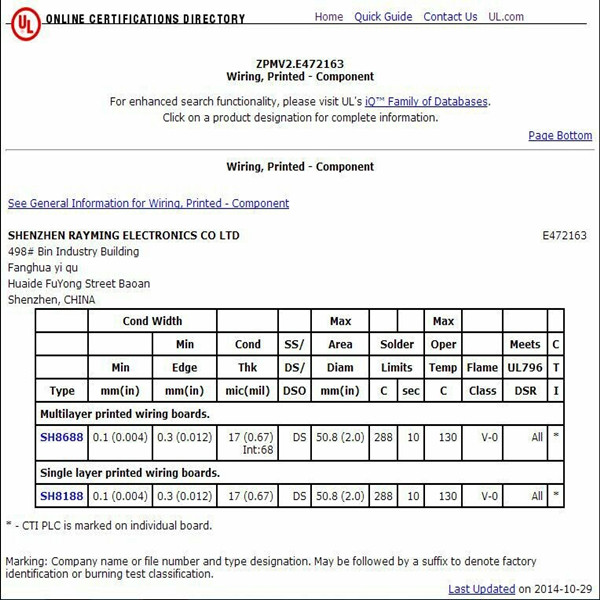

Certifications

Certifications

Packaging & Shipping

Packaging & Shipping  FAQ Quotation Tips(one of them ):

FAQ Quotation Tips(one of them ):

1. Gerber files of the bare PCB board.

2. BOM (Bill of material) for assembly.

3. Testing Guide & Test Fixtures if necessary.

4. Programming files & Programming tool if necessary.

5. Schematic if necessary.

6.provide sample if possible .

| No | Items | Capacity |

| 1. | Layers | 1-20 layers |

| 2. | Max. Board size | 508×610 mm |

| 3. | Min. board Thickness | 2-layer 0.12mm |

| 4. | Min. line Width/Space | 0.127mm(4mil) |

| 5. | Max. Copper thickness | 5OZ |

| 6. | Min. S/M Pitch | 0.075mm(3mil) |

| 7. | Min. hole size | 0.15mm(6mil) |

| 8. | Hole dia. Tolerance (PTH) | ±0.05mm(2mil) |

| 9. | Hole dia. Tolerance (NPTH) | +0/-0.05mm(2mil) |

| 10. | Hole position deviation | ±0.05mm(2mil) |

| 11. | Outline tolerance | ±0.10mm(4mil) |

| 12. | Twist & Bent | <0.7% |

| 13. | Insulation Resistance | 100MΩ Normal |

| 14. | Electric strength | >1.3kv/mm |

| 15. | S/M abrasion | >6H |

| 16. | Thermal stress | 288°C 20Sec |

| 17. | Test Voltage | 50-300V |

| 18. | Min. blind/buried via | 0.15mm (6mil) |

| 19. | Surface Finished | HAL, ENIG, OSP, Plating AG, Plating gold,HAL tin, silver |

| 20. | Materials | FR4,H-TG,Teflon,Rogers,Ceramics,Aluminium, Copper base, CEM-3, CEM-1 |

Company Information RayMing Technology Co.,Ltd was founded in 1997, is a high-teach enterprise specializing in the production of high-level,high-precision printed circuit boards. We have more than 10,000 square meters,with more than 500 professional employees,monthly capability is 20,000sqm,5000types.

Company Information RayMing Technology Co.,Ltd was founded in 1997, is a high-teach enterprise specializing in the production of high-level,high-precision printed circuit boards. We have more than 10,000 square meters,with more than 500 professional employees,monthly capability is 20,000sqm,5000types.

Certifications

Certifications

Packaging & Shipping

Packaging & Shipping  FAQ Quotation Tips(one of them ):

FAQ Quotation Tips(one of them ):1. Gerber files of the bare PCB board.

2. BOM (Bill of material) for assembly.

3. Testing Guide & Test Fixtures if necessary.

4. Programming files & Programming tool if necessary.

5. Schematic if necessary.

6.provide sample if possible .

Related Keywords

Related Keywords