4 layers PCB with HASL lead free finish, green solder mask

- Delivery Time:

- 8 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

Rayming Services Rayming specializes in ABCD Solution, including PCB Assembly, Printed Circuit Board Manufacturing, ElectronicComponents and PCB Copy, PCB Design. More services as below, - Assembly stencils - Fast PCB prototype / PCBA prototype - Surface mount PCB assembly - Through hole assembly - DIP assembly - Bonding assembly - Electromechanical assembly - Final assembly - Full turnkey box build - Cable - PCBA contract manufacturing - Electronic contract manufacturing - Supply chain management - Custom wiring & cabling - Engineering and early design-in support - Other customer technical parts

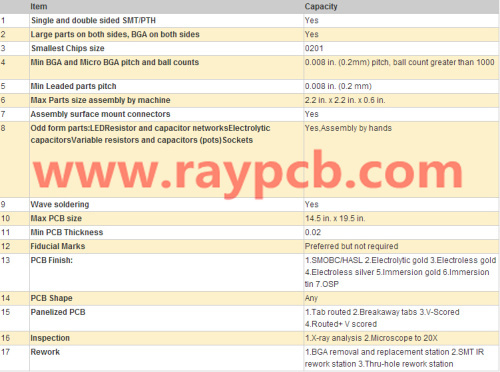

Assembly Capacities

Assembly Capacities 1 | Single and double sided SMT/PTH | Yes |

| 2 | Large parts on both sides, BGA on both sides | Yes |

| 3 | Smallest Chips size | 0201 |

| 4 | Component Height | 0.2-25mm |

| 5 | Min BGA and Micro BGA pitch and ball counts | 0.25-2.0mm pitch, ball count greater than 1000 |

| 6 | BGA Ball Diameter | 0.1-0.63mm |

| 7 | Max Parts size assembly by machine | 55mm x 55mm x 15mm |

| 8 | Assembly surface mount connectors | Yes |

| 9 | Odd form parts: LED Resistor and capacitor networks Electrolytic capacitors Variable resistors and capacitors (pots) Sockets | Yes, Assembly by hands |

| 10 | Wave soldering | Yes |

| 11 | Max PCB size | 510mm x 460mm |

| 12 | Min PCB size | 50mm x 30mm |

| 13 | Min PCB Thickness | 0.02 in. |

| 14 | Fiducial Marks | Preferred |

| 15 | PCB Finish: | 1. SMOBC/HASL |

| 2. Electrolytic gold | ||

| 3. Electroless gold | ||

| 4. Electroless silver | ||

| 5. Immersion gold | ||

| 6. Immersion tin | ||

| 7. OSP | ||

| 16 | PCB Shape | Any |

| 17 | Panelized PCB | 1. Tab routed |

| 2. Breakaway tabs | ||

| 3. V-Scored | ||

| 4. Routed + V-scored | ||

| 18 | Inspection | 1. X-ray analysis |

| 2. Microscope to 20X | ||

| 19 | Rework | 1. BGA removal and replacement station |

| 2. SMT IR rework station | ||

| 3. Thru-hole rework station |

| Technical Requirement | 1. Professional Surface-mounting and Through-hole soldering Technology. |

| Quote & Production Requirement | 1. Gerber File or PCB File for Bare PCB Board Fabrication. 2. BOM for Assembly, PNP(Pick and Place file) and Components Position. |

| OEM/ODM/EMS Services | 1. PCB Assembly, PCB assembly: SMT, PTH, BGA. 2. PCBA and enclosure design. |

| Other PCB Assembly Equipments | 1. Assembly Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4. 2. Reflow Oven: FolunGwin FL-RX860. |

Related Keywords