Mini 14 bar Pressure Module High Resolution Pressure Sensor with IC and SPI Interface

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | United States |

|---|

Product Description

Product Description

Mini 14 bar Pressure Module High Resolution Pressure Sensor with IC and SPI Interface Model Number : MS5803-14BA

GENERAL DESCRIPTION

The MS5803-14BA is a new generation of high resolution pressure sensors with SPI and I2C bus interface. It is optimized for depth measurement systems with a water depth resolution of 1cm and below. The sensor module includes a high linear pressure sensor and an ultra low power 24 bit ΔΣ ADC with internal factory calibrated coefficients. It provides a precise digital 24 Bit pressure and temperature value and different operation modes that allow the user to optimize for conversion speed and current consumption. A high resolution temperature output allows the implementation of a depth measurement systems and thermometer function without any additional sensor. The MS5803-14BA can be interfaced to any microcontroller. The communication protocol is simple, without the need to programming internal registers in the device. The gel protection and antimagnetic stainless steel cap protects against 30 bar overpressure water resistant. This new sensor module generation is based on leading MEMS technology and latest benefits from the Intersema’s proven experience and know-how in high volume manufacturing of pressure modules have been widely used for over a decade. This sensing principle employed leads to very low hysteresis and high stability of both pressure and temperature signal.

Benefit • High resolution module, 0.2 mbar

• Fast conversion down to 1 ms

• Low power, 1 µA (standby < 0.15 µA)

• Integrated digital pressure sensor (24 bit ΔΣ ADC)

• Supply voltage 1.8 to 3.6 V • Operating range: 0 to 14 bar, -40 to +85 °C

• I2C and SPI interface (Mode 0,3)

• No external components (Internal oscillator)

• Excellent long term stability

• Hermetically sealable for outdoor devices Features • Mobile water depth measurements systems • Diving computers • Adventure or multi-mode watches Application Mobile altimeter / barometer systems

Weather control systems

Adventure or multi-mode watches

GPS receivers ABSOLUTE MAXIMUM RATINGS

RECOMMENDED OPERATING CONDITIONS

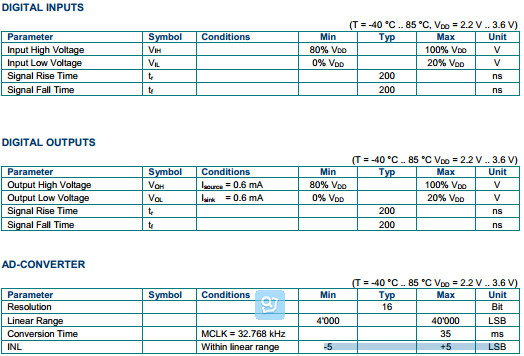

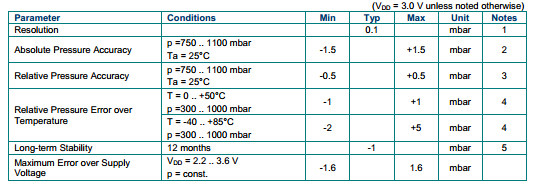

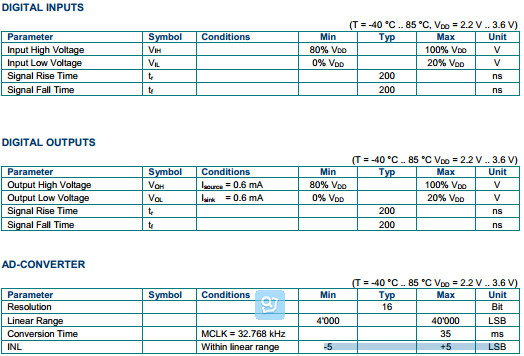

Electrical Cahracteristics  Pressure Output Characteristics With the calibration data stored in the interface IC of the MS5540C, the following characteristics can be achieved:

Pressure Output Characteristics With the calibration data stored in the interface IC of the MS5540C, the following characteristics can be achieved:

NOTES

NOTES

1) A stable pressure reading of the given resolution requires taking the average of 2 to 4 subsequent pressure

values due to noise of the ADC.

2) Maximum error of pressure reading over the pressure range.

3) Maximum error of pressure reading over the pressure range after offset adjustment at one pressure point.

4) With the second-order temperature compensation as described in Section "FUNCTION". See next section

for typical operating curves.

5) The long-term stability is measured with non-soldered devices.

GENERAL DESCRIPTION

The MS5803-14BA is a new generation of high resolution pressure sensors with SPI and I2C bus interface. It is optimized for depth measurement systems with a water depth resolution of 1cm and below. The sensor module includes a high linear pressure sensor and an ultra low power 24 bit ΔΣ ADC with internal factory calibrated coefficients. It provides a precise digital 24 Bit pressure and temperature value and different operation modes that allow the user to optimize for conversion speed and current consumption. A high resolution temperature output allows the implementation of a depth measurement systems and thermometer function without any additional sensor. The MS5803-14BA can be interfaced to any microcontroller. The communication protocol is simple, without the need to programming internal registers in the device. The gel protection and antimagnetic stainless steel cap protects against 30 bar overpressure water resistant. This new sensor module generation is based on leading MEMS technology and latest benefits from the Intersema’s proven experience and know-how in high volume manufacturing of pressure modules have been widely used for over a decade. This sensing principle employed leads to very low hysteresis and high stability of both pressure and temperature signal.

Benefit • High resolution module, 0.2 mbar

• Fast conversion down to 1 ms

• Low power, 1 µA (standby < 0.15 µA)

• Integrated digital pressure sensor (24 bit ΔΣ ADC)

• Supply voltage 1.8 to 3.6 V • Operating range: 0 to 14 bar, -40 to +85 °C

• I2C and SPI interface (Mode 0,3)

• No external components (Internal oscillator)

• Excellent long term stability

• Hermetically sealable for outdoor devices Features • Mobile water depth measurements systems • Diving computers • Adventure or multi-mode watches Application Mobile altimeter / barometer systems

Weather control systems

Adventure or multi-mode watches

GPS receivers ABSOLUTE MAXIMUM RATINGS

| Parameter | Symbol | Conditions | Min | Max | Unit | Notes |

| Supply voltage | VDD | Ta = 25 °C | -0.3 | 4 | V | |

| Storage temperature | TS | -40 | +85 | ℃ | 1 | |

| Overpressure | P | Ta = 25 °C | 10 | bar | 2 |

| Parameter | Symbol | Conditions | Min | Typ | Max | Unit |

| Operating pressure range | P | 10 | 1100 | bar | ||

| Supply voltage | VDD | 2.2 | 3.0 | 3.6 | V | |

| Supply current, average (1) during conversion (2) standby (no conversion) | Iavg Isc Iss | VDD = 3.0 V | 4 1 |

0.1 |

µA | |

| Current consumption into MCLK (3) | MCLK = 32.768 kHz | 0.5 | > µA | |||

| Operating temperature range | T | -40 | +85 | ℃ | ||

| Conversion time | tconv | MCLK = 32.768 kHz | 35 | ms | ||

| External clock signal (4) | MCLK | 30.000 | 32.768 | 35.000 | kHz | |

| Duty cycle of MCLK | 40/60 | 50/50 | 60/40 | % | ||

| Serial data clock | SCLK | 500 | kHZ |

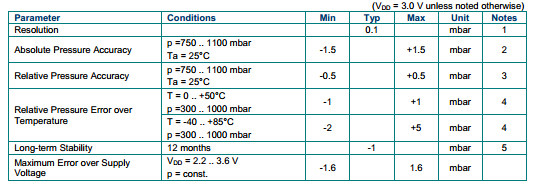

Pressure Output Characteristics With the calibration data stored in the interface IC of the MS5540C, the following characteristics can be achieved:

Pressure Output Characteristics With the calibration data stored in the interface IC of the MS5540C, the following characteristics can be achieved: NOTES

NOTES1) A stable pressure reading of the given resolution requires taking the average of 2 to 4 subsequent pressure

values due to noise of the ADC.

2) Maximum error of pressure reading over the pressure range.

3) Maximum error of pressure reading over the pressure range after offset adjustment at one pressure point.

4) With the second-order temperature compensation as described in Section "FUNCTION". See next section

for typical operating curves.

5) The long-term stability is measured with non-soldered devices.

Related Keywords

Related Keywords

You May Also Like

You May Also Like