argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | United States |

|---|

Product Description

Product Description

Argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters MFI series insertion mass flow meters are designed for gas monitoring and control in a large

pipe line where installation of an in-line flow meter is either difficult or costly. The insertion

minimal interruption to the normal working circumstance. The suggested starting metering DN

is 150 mm and above. All of the insertion meters have an accuracy of ±(1.5+0.5FS)% or

better depending on the requests. The meters can work at an environment of -20 to 60 °C

and pressure up to 1.5 MPa. Applications include but not limited to oxygen, nitrogen,

methane, and compressed air flow monitoring for manufacture process control. Features and Applications

- Highly sensitive, measuring as low as 0.01 Nm/sec, and as high as 65 Nm/sec

- Directly sense mass flow using thermal mass flow principle

- Proprietary MEMS sensor design for better reliability

- Standard 8 ~ 24Vdc power supply

- Low pressure loss reducing energy cost

- Industrial standard communication ports for easy networking and remote control

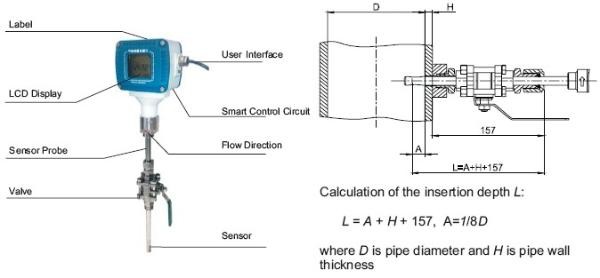

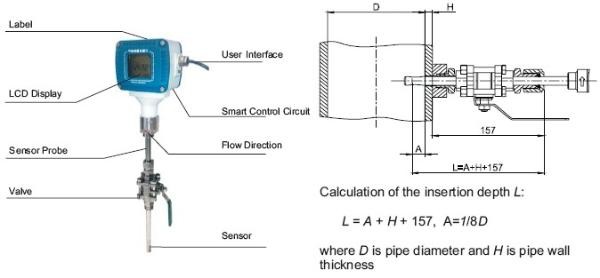

3.Mechanical Dimensions 4.argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters Specifications

4.argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters Specifications

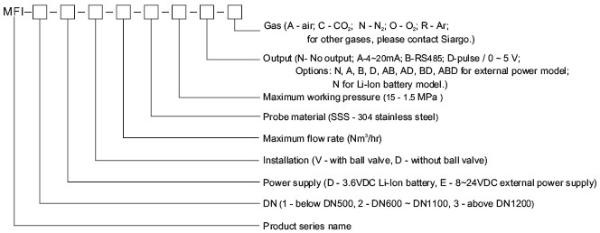

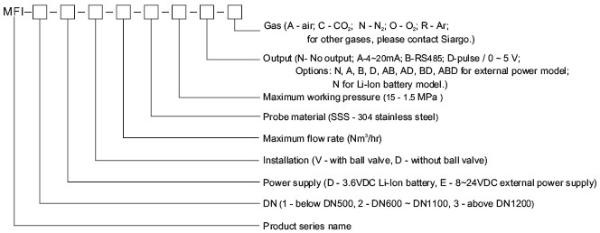

5.argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters Product Selection

5.argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters Product Selection

pipe line where installation of an in-line flow meter is either difficult or costly. The insertion

minimal interruption to the normal working circumstance. The suggested starting metering DN

is 150 mm and above. All of the insertion meters have an accuracy of ±(1.5+0.5FS)% or

better depending on the requests. The meters can work at an environment of -20 to 60 °C

and pressure up to 1.5 MPa. Applications include but not limited to oxygen, nitrogen,

methane, and compressed air flow monitoring for manufacture process control. Features and Applications

- Highly sensitive, measuring as low as 0.01 Nm/sec, and as high as 65 Nm/sec

- Directly sense mass flow using thermal mass flow principle

- Proprietary MEMS sensor design for better reliability

- Standard 8 ~ 24Vdc power supply

- Low pressure loss reducing energy cost

- Industrial standard communication ports for easy networking and remote control

3.Mechanical Dimensions

4.argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters Specifications

4.argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters Specifications

5.argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters Product Selection

5.argon,helium,oxygen,nitrogen gas monitoring and control in a large pipe line Insertion Mass Flow Meters Product Selection

Related Keywords

Related Keywords

You May Also Like

You May Also Like