Liquid Level Sensor for Tank level measurement Price

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | United Kingdom |

|---|

Product Description

Product Description

Liquid Level Sensor for Tank level measurement Price

Model Numder: LLC610D3-003

DESCRIPTION The liquid level sensor provides single point liquid detection via a TTL compatible push pull output.

An infra-red LED and phototransistor accurately positioned at the base of the sensing tip ensure good optical coupling between the two when the sensor is in air. When the sensing tip is immersed in liquid, the infra-red light escapes from the cone causing a change in the amount of light present at the phototransistor which makes the output change state. CLEANING

Proper fluids should be selected based on type of contamination to be removed. SST Sensing recommends freon and alcohol based solvents. DO NOT use chlorinated solvents such as tricholorethane as these are likely to attack the sensor material.

Liquid Media Compatibility

Before use check that the fluid in which you wish to use these devices is compatible with polysulphone.

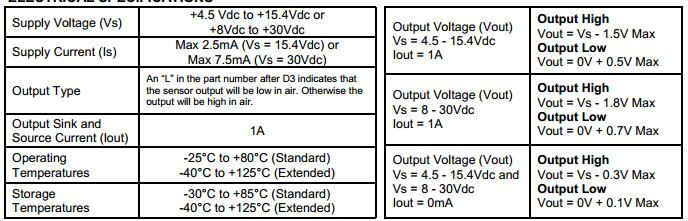

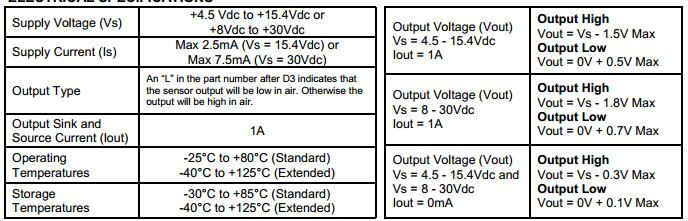

ELECTRICAL SPECIFICATIONS

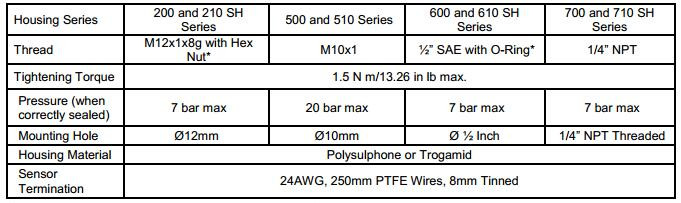

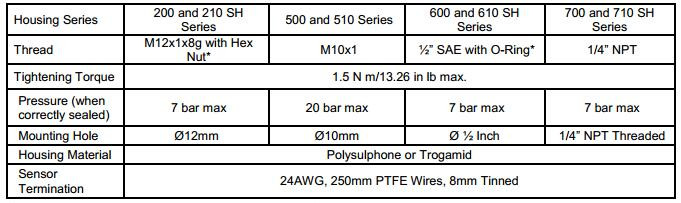

MOUNTING

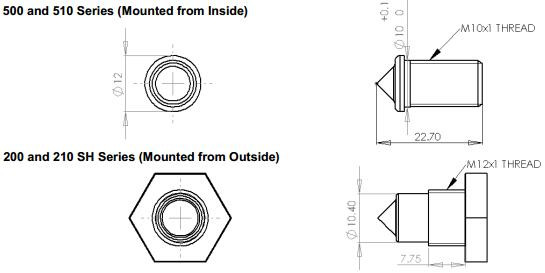

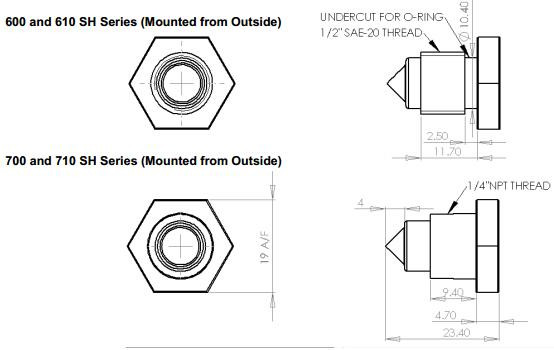

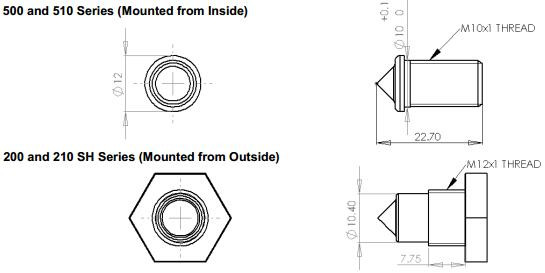

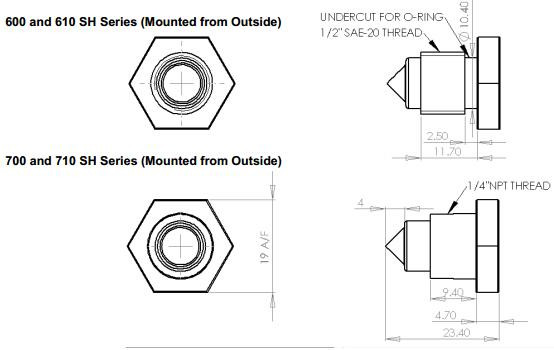

PRODUCT DIMENSIONS(All dimensions in mm)

PRODUCT DIMENSIONS(All dimensions in mm)

SENSOR MOUNTED FROM OUTSIDE VESSEL

SENSOR MOUNTED FROM OUTSIDE VESSEL

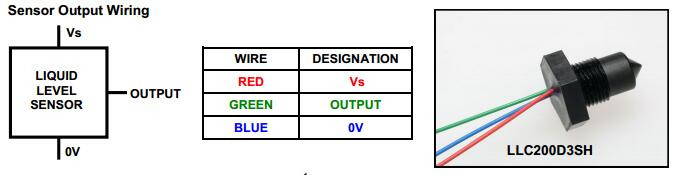

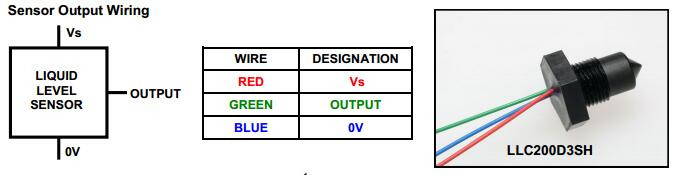

OUTPUT TYPES

In order to suit any application, these sensors have been designed with various output circuit configurations. They are

identified by the a 3-digit code at the end of part number and are as follows:

TAKE CARE WHEN CONNECTING LOADS.

TAKE CARE WHEN CONNECTING LOADS.

The minimum load impedance should not exceed Vs/max current. For example with Vs = 28v then

the minimum load impedance Rload would be 28v/1A = 28Ω. Similarly with Vs = 8v the minimum

load impedance would be 8v/1A = 8Ω.

Model Numder: LLC610D3-003

DESCRIPTION The liquid level sensor provides single point liquid detection via a TTL compatible push pull output.

An infra-red LED and phototransistor accurately positioned at the base of the sensing tip ensure good optical coupling between the two when the sensor is in air. When the sensing tip is immersed in liquid, the infra-red light escapes from the cone causing a change in the amount of light present at the phototransistor which makes the output change state. CLEANING

Proper fluids should be selected based on type of contamination to be removed. SST Sensing recommends freon and alcohol based solvents. DO NOT use chlorinated solvents such as tricholorethane as these are likely to attack the sensor material.

Liquid Media Compatibility

Before use check that the fluid in which you wish to use these devices is compatible with polysulphone.

ELECTRICAL SPECIFICATIONS

MOUNTING

PRODUCT DIMENSIONS(All dimensions in mm)

PRODUCT DIMENSIONS(All dimensions in mm)

SENSOR MOUNTED FROM OUTSIDE VESSEL

SENSOR MOUNTED FROM OUTSIDE VESSEL

OUTPUT TYPES

In order to suit any application, these sensors have been designed with various output circuit configurations. They are

identified by the a 3-digit code at the end of part number and are as follows:

TAKE CARE WHEN CONNECTING LOADS.

TAKE CARE WHEN CONNECTING LOADS.The minimum load impedance should not exceed Vs/max current. For example with Vs = 28v then

the minimum load impedance Rload would be 28v/1A = 28Ω. Similarly with Vs = 8v the minimum

load impedance would be 8v/1A = 8Ω.

Related Keywords

Related Keywords

You May Also Like

You May Also Like