Wide variety of supply and output options liquid level sensor LLC200D3-001

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | United Kingdom |

|---|

Product Description

Product Description

Standard and Extended Temperature Industrial Series Optical Liquid Level Sensors LLC series industrial type Photoelectric liquid level sensor  Feature : low cost high reliability Large drive current can be directly drive motor ,relays guiding lights, alarm Output TTL level Can be customized for customers in large quantities Technical data : working pressure : maximum 78Bar supply voltage : 5~15V or 10~28V ( ±5%) maximum output current :500mV working temperature : below zero 40℃~+125℃ 3 wires or 4 wires output is optional Application : Super wave cleaning equipment Medical equipment Milk liquid level detection Laboratory liquid insulation equipment Food and beverage equipment GENERAL DESCRIPTION

Feature : low cost high reliability Large drive current can be directly drive motor ,relays guiding lights, alarm Output TTL level Can be customized for customers in large quantities Technical data : working pressure : maximum 78Bar supply voltage : 5~15V or 10~28V ( ±5%) maximum output current :500mV working temperature : below zero 40℃~+125℃ 3 wires or 4 wires output is optional Application : Super wave cleaning equipment Medical equipment Milk liquid level detection Laboratory liquid insulation equipment Food and beverage equipment GENERAL DESCRIPTION

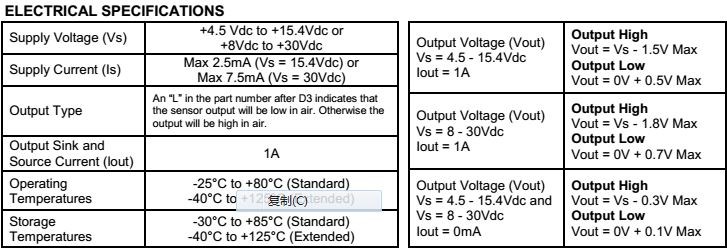

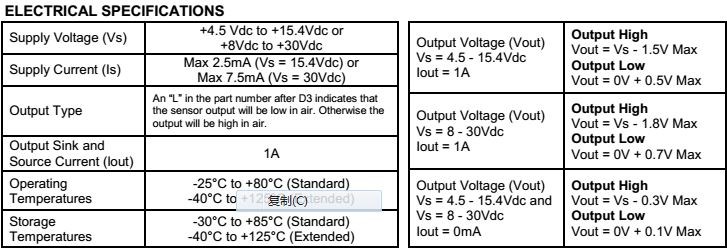

The LLC Industrial Series liquid level sensor provides single point liquid detection via a TTL compatible output.

This sensor range was designed to directly switch incandescent indicators, sounders, relays or applications which require higher output power. An infra-red LED and phototransistor accurately positioned at the base of the sensing tip ensure good optical coupling between the two when the sensor is in air. When the sensing tip is immersed in liquid, the infra-red light escapes from the cone causing a change in the amount of light detected at the phototransistor which makes the output change state. Various electrical outputs are available to suit different applications. CLEANING

Proper fluids should be selected based on type of contamination to be removed. SST Sensing recommends freon and alcohol based solvents. DO NOT use chlorinated solvents such as tricholorethane as these are likely to attack the sensor material.

LIQUID MEDIA COMPATIBILITY

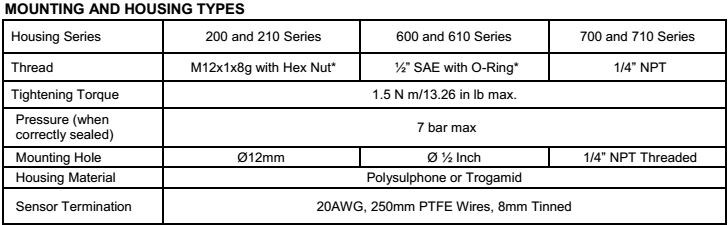

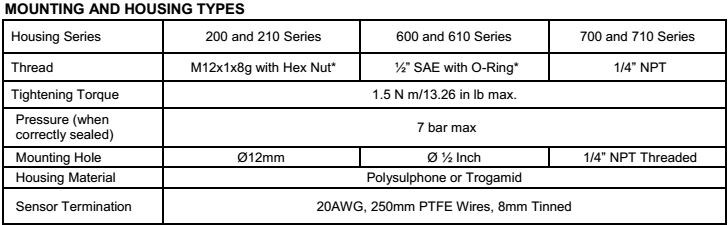

Before use check that the fluid in which you wish to use these devices is compatible with either polysulphone or trogamid

Feature : low cost high reliability Large drive current can be directly drive motor ,relays guiding lights, alarm Output TTL level Can be customized for customers in large quantities Technical data : working pressure : maximum 78Bar supply voltage : 5~15V or 10~28V ( ±5%) maximum output current :500mV working temperature : below zero 40℃~+125℃ 3 wires or 4 wires output is optional Application : Super wave cleaning equipment Medical equipment Milk liquid level detection Laboratory liquid insulation equipment Food and beverage equipment GENERAL DESCRIPTION

Feature : low cost high reliability Large drive current can be directly drive motor ,relays guiding lights, alarm Output TTL level Can be customized for customers in large quantities Technical data : working pressure : maximum 78Bar supply voltage : 5~15V or 10~28V ( ±5%) maximum output current :500mV working temperature : below zero 40℃~+125℃ 3 wires or 4 wires output is optional Application : Super wave cleaning equipment Medical equipment Milk liquid level detection Laboratory liquid insulation equipment Food and beverage equipment GENERAL DESCRIPTIONThe LLC Industrial Series liquid level sensor provides single point liquid detection via a TTL compatible output.

This sensor range was designed to directly switch incandescent indicators, sounders, relays or applications which require higher output power. An infra-red LED and phototransistor accurately positioned at the base of the sensing tip ensure good optical coupling between the two when the sensor is in air. When the sensing tip is immersed in liquid, the infra-red light escapes from the cone causing a change in the amount of light detected at the phototransistor which makes the output change state. Various electrical outputs are available to suit different applications. CLEANING

Proper fluids should be selected based on type of contamination to be removed. SST Sensing recommends freon and alcohol based solvents. DO NOT use chlorinated solvents such as tricholorethane as these are likely to attack the sensor material.

LIQUID MEDIA COMPATIBILITY

Before use check that the fluid in which you wish to use these devices is compatible with either polysulphone or trogamid

Related Keywords

Related Keywords

You May Also Like

You May Also Like