High accuracy linear output Oxygen Sensor Interface O2I-Flex

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | United Kingdom |

|---|

Product Description

Product Description

High accuracy linear output Oxygen Sensor Interface O2I-Flex DESCRIPTION

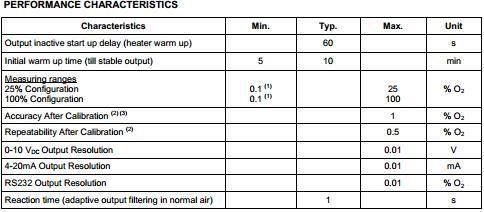

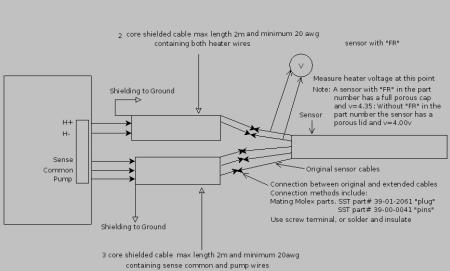

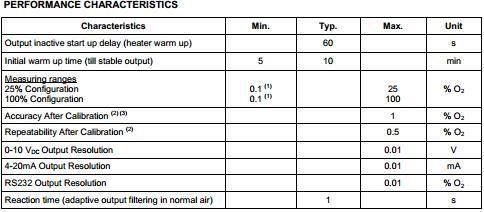

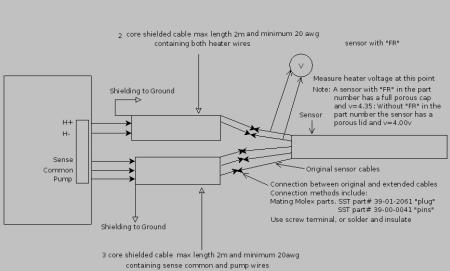

The O2I-FLEX Interface can be user configured to output measuring ranges of 0-25% O2 and 0-100% O2 .The entire measurement range is linear in both cases. Factory default is 0-25% O2. When configured for 0-100% O2 the user can also customise the analogue output ranges to suit their application.

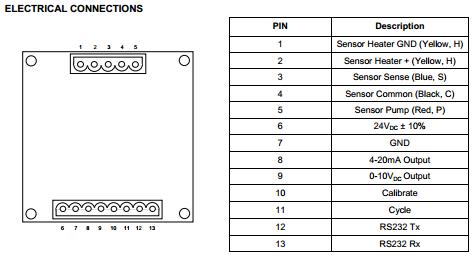

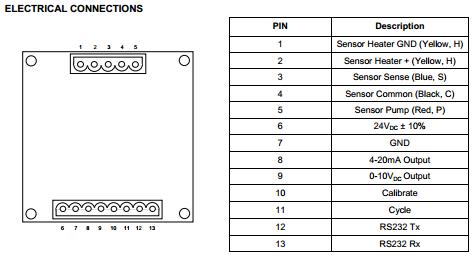

The interface 0utputs the measured values simultaneously via 4 output channels, 4-20mA, 0-10VDC and RS232 (Rx and Tx), all outputs are referenced to the system GND.

A digital 3.3VDC logic output cycles at the same frequency as the electrochemical pumping action of the oxygen sensing cell during normal operation, thus providing a real time sensor health check, if the output ceases to cycle the sensor has entered a start-up or error state. This provides fault proof operation. The digital output is also used during the calibration process to

indicate the interface status.

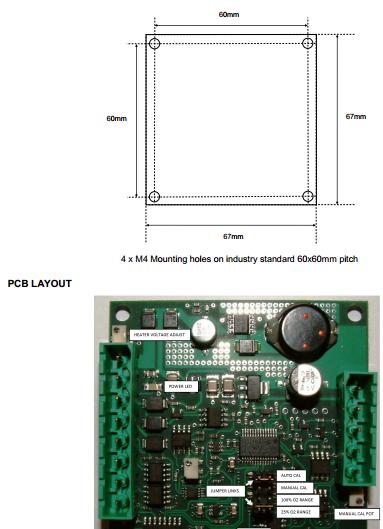

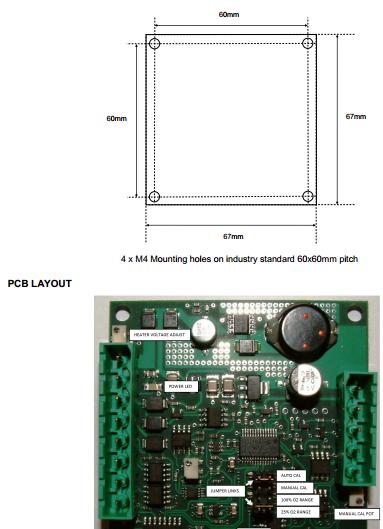

A green on-board LED mirrors the CYCLE output and can be used to visually determine the sensor status or during the calibration process. A red LED indicates the unit has power applied. SST’s range of oxygen sensors do not directly measure the oxygen concentration but instead measure the partial pressure of oxygen within the measurement gas. In order to output an oxygen concentration (%) the O2I-FLEX must be calibrated, or more specifically, re-referenced in a known gas concentration, typically normal air. Calibration, or re-referencing, is achieved by connecting the calibration input to GND or by pressing the on-board calibration switch and monitoring the status of the digital cycle output or by visually monitoring the on-board green LED. During the calibration process the output will either automatically calibrate to a fixed reference or can be manually calibrated to any output by way of a PCB mounted potentiometer. The fixed reference is factory set to 20.7% O2 for calibration in normal air though this value may be altered via the RS232 interface for calibration with a reference gas of any known oxygen concentration. Calibration is stored on power loss. The auto or manual calibrate function is user configurable. Regular calibration removes the effects of

application and atmospheric pressure changes and also eliminates any sensor drift that may occur during the first few hundred hours of operation.

The O2I-FLEX Interface can be user configured to output measuring ranges of 0-25% O2 and 0-100% O2 .The entire measurement range is linear in both cases. Factory default is 0-25% O2. When configured for 0-100% O2 the user can also customise the analogue output ranges to suit their application.

The interface 0utputs the measured values simultaneously via 4 output channels, 4-20mA, 0-10VDC and RS232 (Rx and Tx), all outputs are referenced to the system GND.

A digital 3.3VDC logic output cycles at the same frequency as the electrochemical pumping action of the oxygen sensing cell during normal operation, thus providing a real time sensor health check, if the output ceases to cycle the sensor has entered a start-up or error state. This provides fault proof operation. The digital output is also used during the calibration process to

indicate the interface status.

A green on-board LED mirrors the CYCLE output and can be used to visually determine the sensor status or during the calibration process. A red LED indicates the unit has power applied. SST’s range of oxygen sensors do not directly measure the oxygen concentration but instead measure the partial pressure of oxygen within the measurement gas. In order to output an oxygen concentration (%) the O2I-FLEX must be calibrated, or more specifically, re-referenced in a known gas concentration, typically normal air. Calibration, or re-referencing, is achieved by connecting the calibration input to GND or by pressing the on-board calibration switch and monitoring the status of the digital cycle output or by visually monitoring the on-board green LED. During the calibration process the output will either automatically calibrate to a fixed reference or can be manually calibrated to any output by way of a PCB mounted potentiometer. The fixed reference is factory set to 20.7% O2 for calibration in normal air though this value may be altered via the RS232 interface for calibration with a reference gas of any known oxygen concentration. Calibration is stored on power loss. The auto or manual calibrate function is user configurable. Regular calibration removes the effects of

application and atmospheric pressure changes and also eliminates any sensor drift that may occur during the first few hundred hours of operation.

Related Keywords

Related Keywords

You May Also Like

You May Also Like