Signal Conditioner with Fiber Optic Sensor for temperature, pressure, strain, refractive index measure UMI Series

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Canada |

|---|

Product Description

Product Description

Signal Conditioner with Fiber Optic Sensor for temperature, pressure, strain Model Number: UMI Series Description The UMI is a tabletop, fi ber optic signal conditioner especially designed to

work with all of FISO’s fi ber optic sensors. It is a general-purpose instrument

ideally suited to perform multi-point temperature, pressure, strain, refractive

index and displacement measurements in a myriad of industrial and R&D

applications in hostile environments.

The UMI conditioner is designed to perform accurate multi-channel temperature,

pressure, strain, refractive index, and displacement measurements. Thanks to its

unique, patented technology, the UMI conditioner is capable of measuring the

absolute cavity length of FISO’s Fabry-Perot fi ber optic sensors with astonishing

accuracy, provi ding highly accurate and reliable measurements. The UMI has a

0.01% full-scale resolution and a 0.025% full-scale precision.

FISO’s fi ber optic sensors offer complete immunity to RF and microwave radiation

with high temperature operating capability, intrinsic safety, and non-invasive use.

The UMI comes in a 4-channel or in an 8-channel version. All optical input channels

are easily accessible through the unit’s front panel. The system scans all the channels

in use sequentially with a switching time of 0.15 seconds. It can also read on

a discrete channel at a 20 Hz sampling rate. Data is stored in the internal memory

buffer for later retrieval or sent directly to any analog input signal reading device

through the ±5 V adjustable analog output available for each channel on the

back panel of the UMI unit.

A seven-digit gauge factor assigned to each sensor allows the UMI conditioner to

reco gnize automatically the sensor type and calibration, reducing test setup time.

The UMI conditioner has a non-volatile memory buffer that can store up to 50 000

data points. Data logging sequences, duration, and other acquisition and datamanagement

parameters are easily programmable using the front-panel interface,

through remote control commands or, even more easily, thanks to its accompanying

software, FISOCommander. Moreover, its Flash ROM allows fi rmware

upgrades. Key Features - 4 or 8 channels

- ±5 V Analog output

- RS-232 and USB communication ports

- Up to 20 Hz sampling rate

- Large VFD Display

- Compatible with all of FISO’s

- ber optic sensors Applications - Microwave food processing

- Microwave packaging design

- Thermotherapy applications

- NMR

- Automotive

- Aerospace

- High temperature displacement measurement

- Multi-purpose laboratory applications

- In-situ process monitoring

- Civil engineering

- New material research

- Hazardous environments Specifi cations

Number of channels 4 or 8

Sampling rate 20 Hz

Switching time 150 ms

Averaging 1 to 500 samples

Precision 0.025% of full scale

Resolution 0.01% of full scale

Dynamic range 15 000 : 1

Display 4 lines by 20 characters Vacuum Fluorescent Display

Data logging 50 000 data points

Analog outputs ±5 V software adjustable in scale and offset

Communication RS-232; USB

Upgradeability Flash ROM fi rmware

Lamp life1 40 000 hours of continuous use

Weight 2.2 kg (4.9 lb)

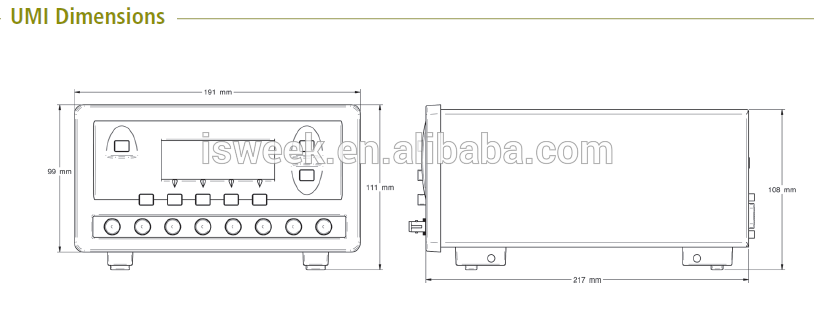

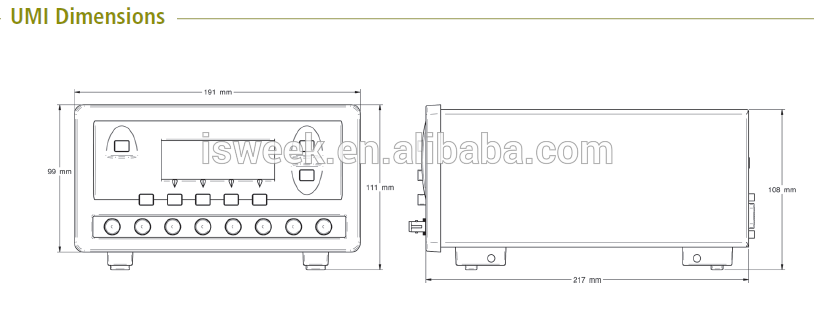

Dimensions (W × D × H) 191 × 217 × 99 mm (7.2 × 8.5 × 3.9 in)

Power requirements 10 to 20 Volts (5 Watts)

Operating temperature −20°C to 40°C (−4°F to 104°F)

Contact :

Contact :

work with all of FISO’s fi ber optic sensors. It is a general-purpose instrument

ideally suited to perform multi-point temperature, pressure, strain, refractive

index and displacement measurements in a myriad of industrial and R&D

applications in hostile environments.

The UMI conditioner is designed to perform accurate multi-channel temperature,

pressure, strain, refractive index, and displacement measurements. Thanks to its

unique, patented technology, the UMI conditioner is capable of measuring the

absolute cavity length of FISO’s Fabry-Perot fi ber optic sensors with astonishing

accuracy, provi ding highly accurate and reliable measurements. The UMI has a

0.01% full-scale resolution and a 0.025% full-scale precision.

FISO’s fi ber optic sensors offer complete immunity to RF and microwave radiation

with high temperature operating capability, intrinsic safety, and non-invasive use.

The UMI comes in a 4-channel or in an 8-channel version. All optical input channels

are easily accessible through the unit’s front panel. The system scans all the channels

in use sequentially with a switching time of 0.15 seconds. It can also read on

a discrete channel at a 20 Hz sampling rate. Data is stored in the internal memory

buffer for later retrieval or sent directly to any analog input signal reading device

through the ±5 V adjustable analog output available for each channel on the

back panel of the UMI unit.

A seven-digit gauge factor assigned to each sensor allows the UMI conditioner to

reco gnize automatically the sensor type and calibration, reducing test setup time.

The UMI conditioner has a non-volatile memory buffer that can store up to 50 000

data points. Data logging sequences, duration, and other acquisition and datamanagement

parameters are easily programmable using the front-panel interface,

through remote control commands or, even more easily, thanks to its accompanying

software, FISOCommander. Moreover, its Flash ROM allows fi rmware

upgrades. Key Features - 4 or 8 channels

- ±5 V Analog output

- RS-232 and USB communication ports

- Up to 20 Hz sampling rate

- Large VFD Display

- Compatible with all of FISO’s

- ber optic sensors Applications - Microwave food processing

- Microwave packaging design

- Thermotherapy applications

- NMR

- Automotive

- Aerospace

- High temperature displacement measurement

- Multi-purpose laboratory applications

- In-situ process monitoring

- Civil engineering

- New material research

- Hazardous environments Specifi cations

Number of channels 4 or 8

Sampling rate 20 Hz

Switching time 150 ms

Averaging 1 to 500 samples

Precision 0.025% of full scale

Resolution 0.01% of full scale

Dynamic range 15 000 : 1

Display 4 lines by 20 characters Vacuum Fluorescent Display

Data logging 50 000 data points

Analog outputs ±5 V software adjustable in scale and offset

Communication RS-232; USB

Upgradeability Flash ROM fi rmware

Lamp life1 40 000 hours of continuous use

Weight 2.2 kg (4.9 lb)

Dimensions (W × D × H) 191 × 217 × 99 mm (7.2 × 8.5 × 3.9 in)

Power requirements 10 to 20 Volts (5 Watts)

Operating temperature −20°C to 40°C (−4°F to 104°F)

Contact :

Contact :

Related Keywords

Related Keywords

You May Also Like

You May Also Like