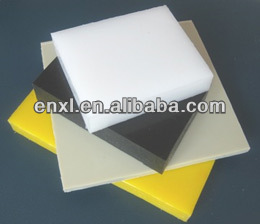

professional manufacturer 100% virgin engineering plastics HDPE sheets

- Delivery Time:

- 7 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

1.100% virgin material

2.1.Own brand: EnXL

3.Color: white, Natural, grey, black, others can be customize

Detailed descriptiion 100% virgin engineering plastics manuafcturer HDPE Sheets Product Specification/Models Mould pressing: (30-200)*1000*2000mm (30-200)*6000*2000mm (30-100)*1040*3100mm (30-200)*3100*1500mm (30-300)*1220*2440mm (30-150)*4600*2000mm (30-200)*4800*1300mm (30-150)*4000*1200mm (30-200)*5100*1500mm (30-300)*1550*7150mm Extrusion: (5-30mm)*2300mm*any length Advantages and properties Low friction properties which are some of the best within the engineering plastics range and HDPE Sheet helps produce low friction components. 2) Excellent abrasion resistance which helps provide components that are suitable for high abrasion applications. HDPE Sheet will absorb very low amounts of moisture which help creates components that are stable over a long period of time and also help this product attain Food & Drug Administration Approval which can help in the food industry. 3) Economical and can provide an engineering plastic with equal or greater performance advantages and save end users a significant amount of money. 4)Light and easy to machine to help improve machining times. 5)Very tough and almost impossible to break which helps produce components that are tough and can stand up to a lot of punishment in high impact environments. Application

variety | application |

high abrasion-resistance | storehouse wall,port machinery,miningmachinery,building machinery,chute,hopper. |

pure ultra-high sheet | transportmachinery,foods,package,environmental protection,papermaking,ceramica. |

electrostatic-resistance sheet | electrostatic protecting positions for mining in the pit,dock,and foods processing. |

burning-preventing sheet | mning in the pit,mainly used in easily self-inflammation parts,such as coal storehouse. |

color sheet | packaging,decorative material,board fender |

double-color sheet | wear easily found and easily check. |

micro-hole sheet | filter-sheet. |

Relative density (g/cm3) | 0.920.97 | Brittle temperature () | <-120 |

Water absorption (%) | <0.01 | Linear expanding coefficient (X10-5k-1) | 1213 |

In-process shrinkage (%) | 1.55.5- | Thermal conductivity (W/(m.k)) | 0.44 |

Tensile strength (Mpa) | 21--37 | Volume resistivity (Ω.cm) | 61015 |

Breaking extension (%) | >880 | Dielectric constant (106HZ) | 2.34-2.35 |

Bending strength (Mpa) | 11 | Dielectric dissipation factor | 0.0003 |

Compressive strength (Mpa) | 10 | Dielectric strength/(KV/mm) | >20 |

Notch impact strength (Kj/ m2) | 4070 | Arc resistant/s | 115 |

Rockwell hardness | R70 | Oxygen index (%) | -20 |

Heat-formation temperature () | 75 |

|

|

Related Keywords