Custom Precision Plastic moulding parts pp material

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Custom Precision Plastic moulding parts pp material About Splendor: Our Splendor is the leader in designing, developing and manufacturing precision plastic mould, plastic injection moulding, silicone rubber keypads and die cast.

We can customize all kinds of Precision Plastic Mould based on your drawings\samples, the plastic injection molding will be apply to Medical, Enviromental, Electronic, Automotive,Military, Home Appliance and Transporation Industrial etc. See what our Splendor Can do for you: • Strong Technical Support: We have a technical R&D department with professional egineers, which can offer you with engineering and technical design support in mold and product design. • Strick Quality Control System: As a ISO 9001 certificated manufacturer, we will offer you the high quality products. • Supeior Service: Our professional sales staffs would answer you in time, there is no communication probolem. • Stability and Reasonable Price: We are real factory, there is no middlemen commission, which will help you to save cost. • Speedy Delivery: Mould delivery time is 15-45 days according to its structure and size. 7-20days for mass production according to order quantity.

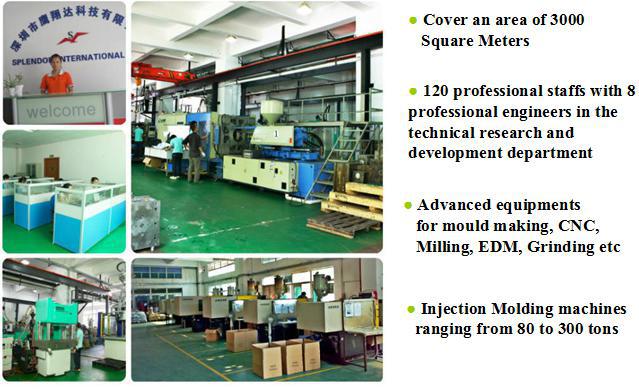

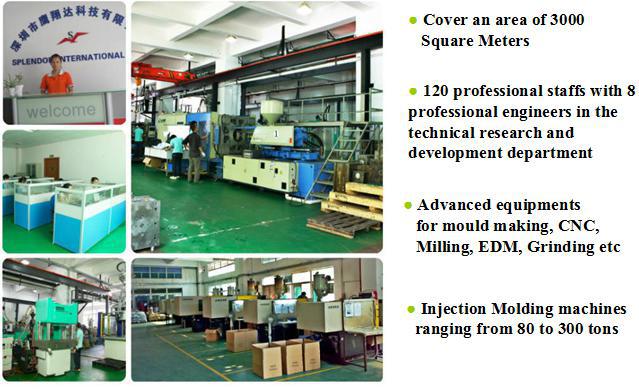

Follow us to visit our facotry:Cooperation with direct manufacturer for cost saving and high quality. 1. Company Landscape  2. Workshop:

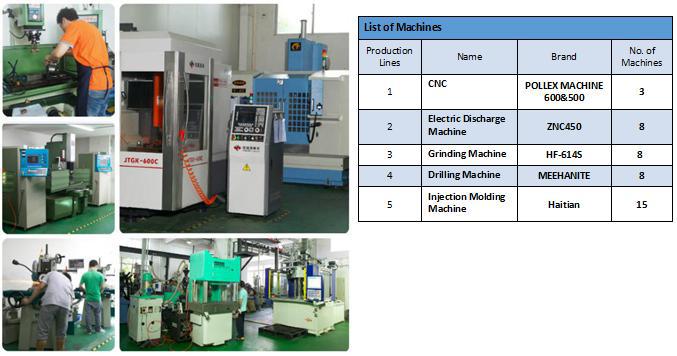

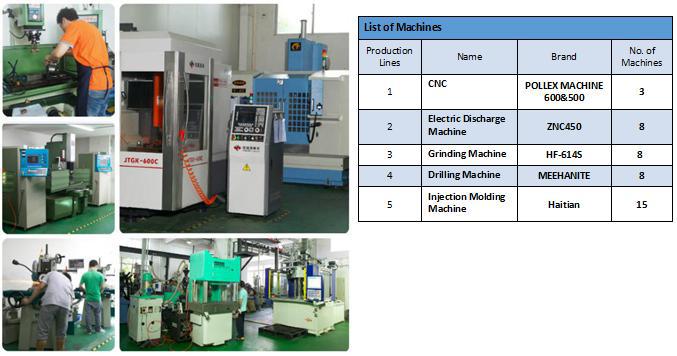

2. Workshop:  3. Machines

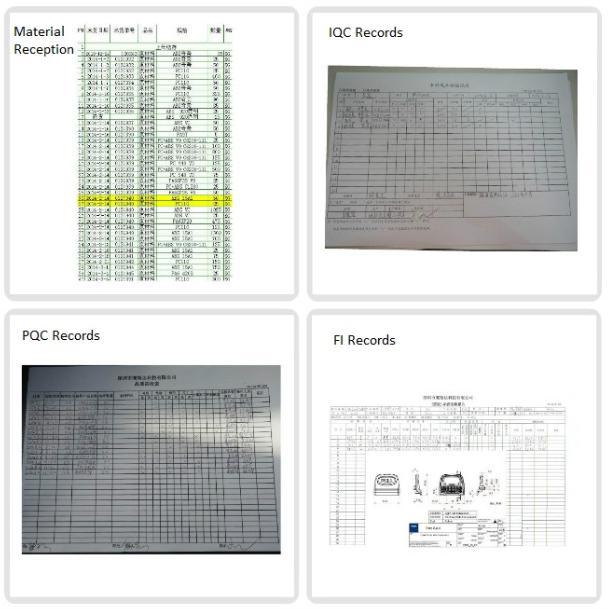

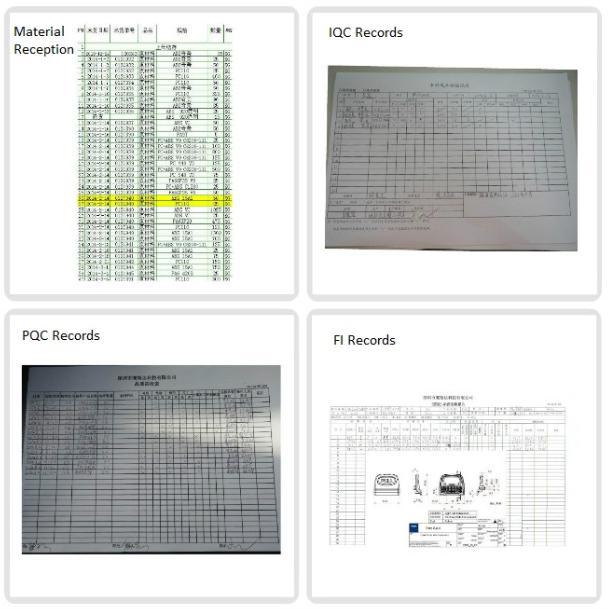

3. Machines  4.1 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable

4.1 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable  4.2 Manufacturing Process

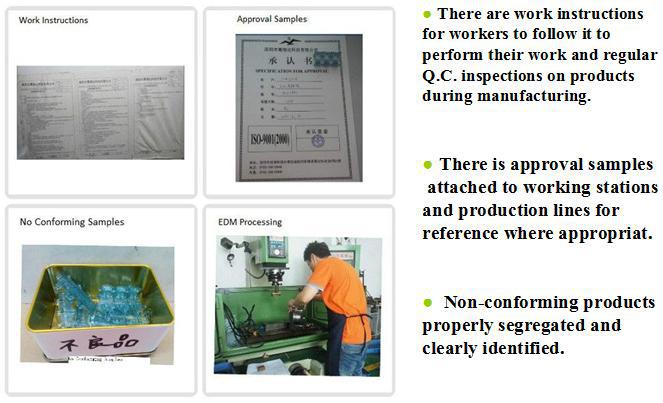

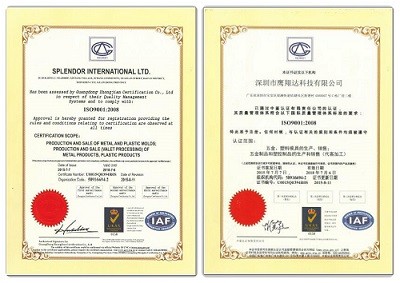

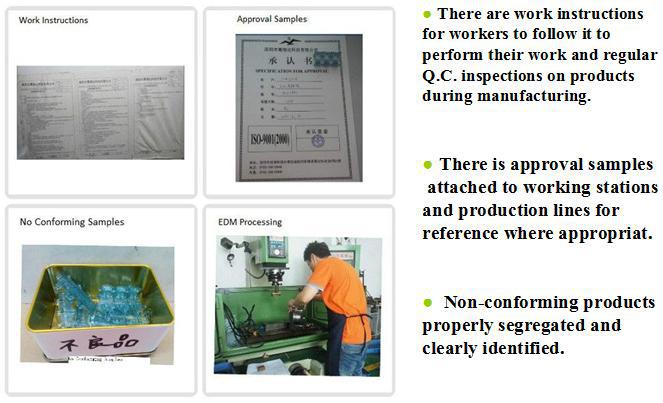

4.2 Manufacturing Process  4.3 Quality Management: Certificated by ISO9001:2008 • There are 2 QC Managers to head the Quality Control function. • Quality Manual for workers to keep high quality in mind • There is a developed quality control plan showing inspection procedures used during manufacturing

4.3 Quality Management: Certificated by ISO9001:2008 • There are 2 QC Managers to head the Quality Control function. • Quality Manual for workers to keep high quality in mind • There is a developed quality control plan showing inspection procedures used during manufacturing  4.4.Final Inspection and QA Testing • There are adequate instructions available for inspectors to follow for final inspection • Inspection & Testing are performed on products before packing and final inspection before shipment.

4.4.Final Inspection and QA Testing • There are adequate instructions available for inspectors to follow for final inspection • Inspection & Testing are performed on products before packing and final inspection before shipment.  4.5 Warehouse

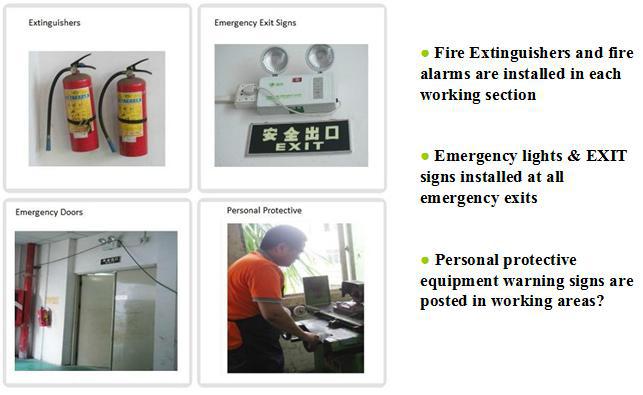

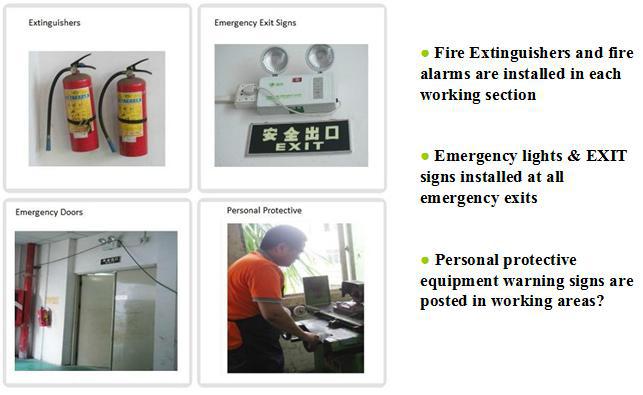

4.5 Warehouse  4.6 Emergency Facilities

4.6 Emergency Facilities  5. Our Customers: Our Splendor have many customers in Russia,USA,UK, Canada, Greece,Turkey etc. We are the top supplier of TEXA, SST, Pyronix for more than ten years. As we always satisfied our customers with high quality, superior service and punctual delivery, we have gained good reputation from them.

5. Our Customers: Our Splendor have many customers in Russia,USA,UK, Canada, Greece,Turkey etc. We are the top supplier of TEXA, SST, Pyronix for more than ten years. As we always satisfied our customers with high quality, superior service and punctual delivery, we have gained good reputation from them.  6. Exhibition: Mould Eurasia 2012 in Turkey ; ROSMOULD 2013 & 2014 in Russia

6. Exhibition: Mould Eurasia 2012 in Turkey ; ROSMOULD 2013 & 2014 in Russia  Your Idea, our Splendor help you to make it into Reality! Plastic Contact with Ms Helen Liu, I will send you our company presentation for you learn more about our Splendor!

Your Idea, our Splendor help you to make it into Reality! Plastic Contact with Ms Helen Liu, I will send you our company presentation for you learn more about our Splendor!

We can customize all kinds of Precision Plastic Mould based on your drawings\samples, the plastic injection molding will be apply to Medical, Enviromental, Electronic, Automotive,Military, Home Appliance and Transporation Industrial etc. See what our Splendor Can do for you: • Strong Technical Support: We have a technical R&D department with professional egineers, which can offer you with engineering and technical design support in mold and product design. • Strick Quality Control System: As a ISO 9001 certificated manufacturer, we will offer you the high quality products. • Supeior Service: Our professional sales staffs would answer you in time, there is no communication probolem. • Stability and Reasonable Price: We are real factory, there is no middlemen commission, which will help you to save cost. • Speedy Delivery: Mould delivery time is 15-45 days according to its structure and size. 7-20days for mass production according to order quantity.

| 1 | Mould base material | LKM, HASCO, LOCAL ,DME, etc |

| 2 | Mould core material | 718H, S136H, NAK80 , P20, etc |

| 3 | Plastic molded parts material | ABS, ABS+PC, PC, PP, PVC, |

| 4 | Cavity | Single, Multi |

| 5 | Runner | Hot & Cold Runner |

| 6 | Finish | Semi-Matt, Polish |

| 7 | Design software | Pro-E, IGES, UG, CAD CAXA, ect |

| 8 | Main processing equipment | CNC, Cutting, Carved, Milling, EDM |

| 9 | Arrangement type | I-section, Straight body mould |

| 10 | Second Processing | Silk-scree Printing, Plating, Painting |

| 11 | Package | Wooden case for mould, carton box for Plastic moulding parts |

| 12 | Delivery time | 15-45 days for mould and samples of Plastic moulding parts, 7days for mass production. |

| 13 | Trade Term | Ex-works, FOB Shenzhen, CIF |

| 14 | Payment Term | Paid By T/T |

2. Workshop:

2. Workshop:  3. Machines

3. Machines  4.1 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable

4.1 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable  4.2 Manufacturing Process

4.2 Manufacturing Process  4.3 Quality Management: Certificated by ISO9001:2008 • There are 2 QC Managers to head the Quality Control function. • Quality Manual for workers to keep high quality in mind • There is a developed quality control plan showing inspection procedures used during manufacturing

4.3 Quality Management: Certificated by ISO9001:2008 • There are 2 QC Managers to head the Quality Control function. • Quality Manual for workers to keep high quality in mind • There is a developed quality control plan showing inspection procedures used during manufacturing  4.4.Final Inspection and QA Testing • There are adequate instructions available for inspectors to follow for final inspection • Inspection & Testing are performed on products before packing and final inspection before shipment.

4.4.Final Inspection and QA Testing • There are adequate instructions available for inspectors to follow for final inspection • Inspection & Testing are performed on products before packing and final inspection before shipment.  4.5 Warehouse

4.5 Warehouse  4.6 Emergency Facilities

4.6 Emergency Facilities  5. Our Customers: Our Splendor have many customers in Russia,USA,UK, Canada, Greece,Turkey etc. We are the top supplier of TEXA, SST, Pyronix for more than ten years. As we always satisfied our customers with high quality, superior service and punctual delivery, we have gained good reputation from them.

5. Our Customers: Our Splendor have many customers in Russia,USA,UK, Canada, Greece,Turkey etc. We are the top supplier of TEXA, SST, Pyronix for more than ten years. As we always satisfied our customers with high quality, superior service and punctual delivery, we have gained good reputation from them.  6. Exhibition: Mould Eurasia 2012 in Turkey ; ROSMOULD 2013 & 2014 in Russia

6. Exhibition: Mould Eurasia 2012 in Turkey ; ROSMOULD 2013 & 2014 in Russia  Your Idea, our Splendor help you to make it into Reality! Plastic Contact with Ms Helen Liu, I will send you our company presentation for you learn more about our Splendor!

Your Idea, our Splendor help you to make it into Reality! Plastic Contact with Ms Helen Liu, I will send you our company presentation for you learn more about our Splendor! Related Keywords

Related Keywords