Injection Plastic Moulding Design Mould Making & Plastic Housing making

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

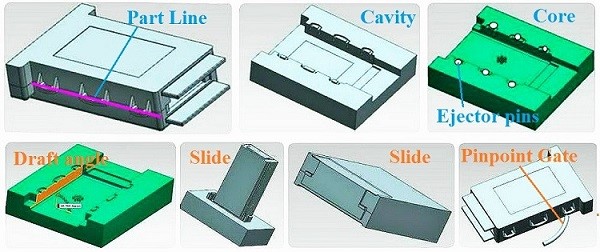

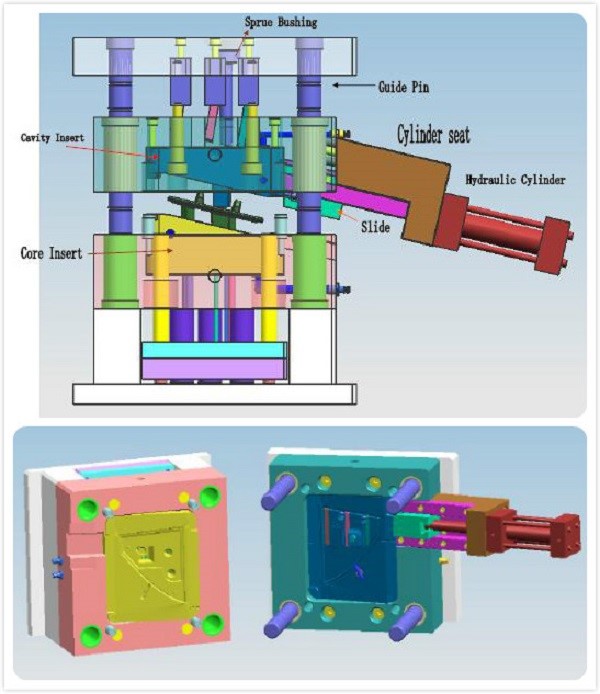

Injection Plastic Moulding Design Mould Making & Plastic Housing making Features: 1. Mould Base Mat6.erial: LKM, HASKCO, LOCAL, DME, etc 2. Mould Core Material: 718H, S136H, NAK80,P20,etc 3. Plastic Injectiong Molding Material: ABS, ABS+PC, PC, PP, PVC 4. Cavity: Single & Multi Cavity 5. Runner: Hot & Cold Runner 6. Finish: Semi-matt, Polish 7. Design Software: Pro-E, Iges, UG, CAD, CAXA, etc 8. Main Processing Equipment: CNC, Cutting, Carved, Milling, EDM 9. Arragement Type: I-section, Straight body mould 10. Second Processing: Silk-screen Printing,Plating, Painting, Ultrasond, Fit screw and so on. 11. Delivery Time: 15-45 days for mould making according to structure and size. 7-20days for mass production according to order quantity. 12. Package: Wooden case for mould, carton box for plastic injection molding, plastic product, plastic component. 13. Trade Term: Ex-works, FOB Shenzhen, CIF 14. Payment Term: Paid By T/T Cooperation with our factory directly for reasonable price, high quality, superior service and punctual delivery! See What our Splendor Can do for you: • Strong Technical Support: We have a technical R&D department with professional engineers, which can offer you with engineering and technical design support in mold and product design. • Strick Quality Control System: As a ISO 9001:2008 certificated manufacturer, we will offer you the high quality products. • Superior Service: Our professional sales staffs would answer you in time, there is no communication problem. • Stability and Reasonable Price: We are real factory, there is no middlemen commission, which can help you to save cost. • Speed Delivery: Mould delivery time is 15-45 days according to its structure and size. 7-20days for mass production according to order quantity. See how to make your Injection Plastic Moulding: 01. Analysis Report Before Injection Plastic Moulding Making: If necessary, we can send you analysis report for you learn mould design information before mould making.  02. Design 3D Mould Drawing • Our Engineer will design 3D mould drawing for your confirmation. • Design Software: Pro-E, Iges, UG, CAD etc • Mould Base Material: LKM, HASKCO, LOCAL, DME etc • Mould Core Material: 718H, S136H, NAK80, P20 ect • Mould Cavity: Single & Multi Cavity • Runner: Cold or Hot Runner • Gate: Pinpoint Gate or Edge Gate • Finish: Polish or Semi-matt

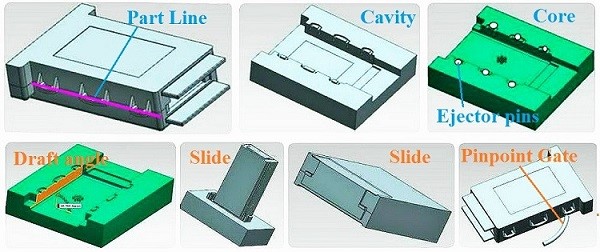

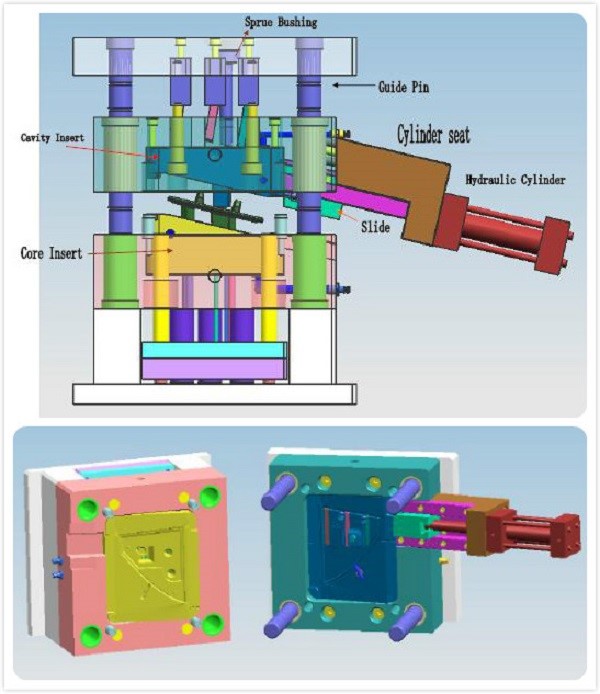

02. Design 3D Mould Drawing • Our Engineer will design 3D mould drawing for your confirmation. • Design Software: Pro-E, Iges, UG, CAD etc • Mould Base Material: LKM, HASKCO, LOCAL, DME etc • Mould Core Material: 718H, S136H, NAK80, P20 ect • Mould Cavity: Single & Multi Cavity • Runner: Cold or Hot Runner • Gate: Pinpoint Gate or Edge Gate • Finish: Polish or Semi-matt  03. Injection Plastic Moulding Making • Main Processing Equipment: CNC Machines, Milling Machines, Grinding Machine, EDM etc. • 15-45 days for mould making and first sampples.

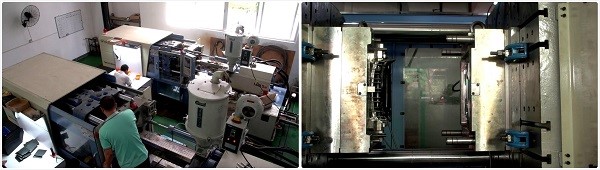

03. Injection Plastic Moulding Making • Main Processing Equipment: CNC Machines, Milling Machines, Grinding Machine, EDM etc. • 15-45 days for mould making and first sampples.  04. Trial Mould

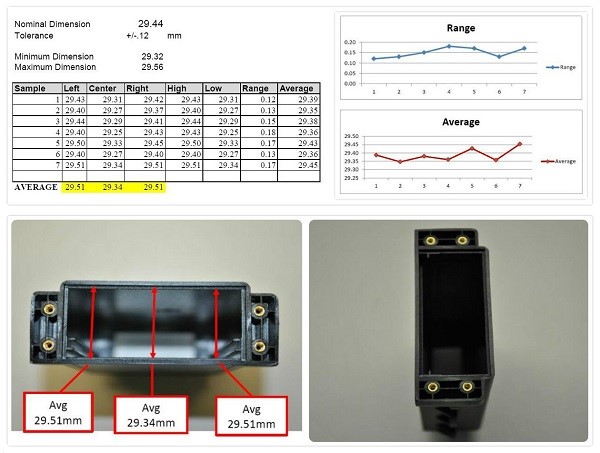

04. Trial Mould  05. Test Samples

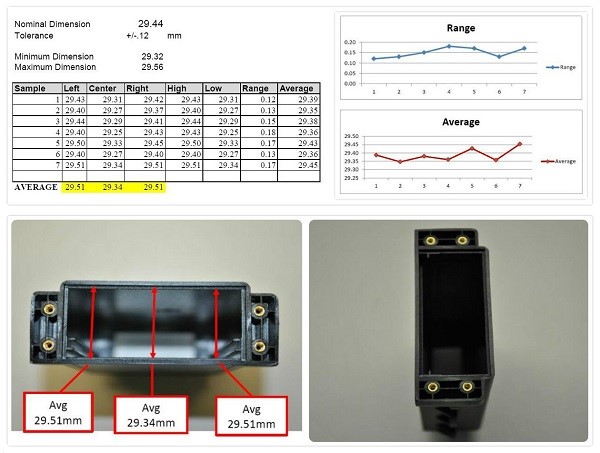

05. Test Samples  06. Mass Production after customer confirmed samples. • Material Reception, Incoming Quality Check(IQC) Records, Production Quality Check(PQC) records and Final Inspection(FI) records are availiable. • There are work instructions for workers to follow it to perform their work and regular QC Inspections on products during manufacturing. • There is approval samples attached to working stations and production lines for reference where appropriate. Non-conforming products properly segregated and clearly identified. • 7-20 days for mass production.

06. Mass Production after customer confirmed samples. • Material Reception, Incoming Quality Check(IQC) Records, Production Quality Check(PQC) records and Final Inspection(FI) records are availiable. • There are work instructions for workers to follow it to perform their work and regular QC Inspections on products during manufacturing. • There is approval samples attached to working stations and production lines for reference where appropriate. Non-conforming products properly segregated and clearly identified. • 7-20 days for mass production.  07. Second Processing: Silk-Screen Printing, Painting, Ultrasound, Assembly and so on.

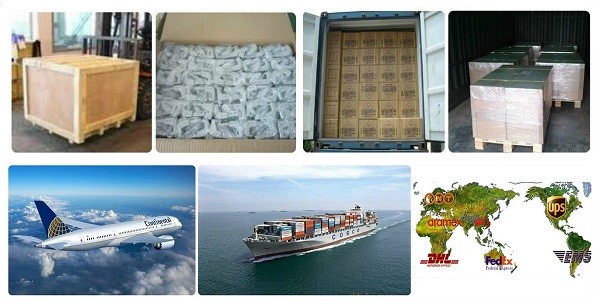

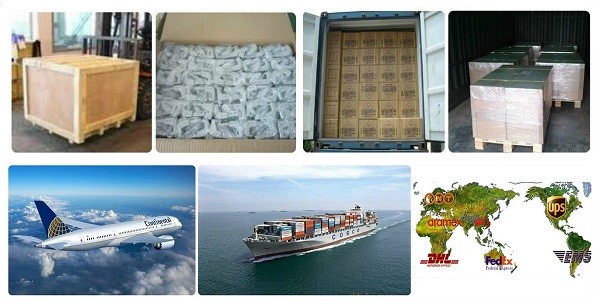

07. Second Processing: Silk-Screen Printing, Painting, Ultrasound, Assembly and so on.  08. Package and Shipment • Wooden case for Plastic Injection Mould • Inner package for plastic injection products: 1pcs/polybag. Carton box for out package. If necessary, cartons would be place to pallets. • Our factory is near to Yantian&Shekou port, Baoan Airport and Hongkong. It takes 45 minutes go to Yantian&Shekou port and Baoan Aiport. It takes about one and half an hour go to Hongkong. It is convenient for tranportation.

08. Package and Shipment • Wooden case for Plastic Injection Mould • Inner package for plastic injection products: 1pcs/polybag. Carton box for out package. If necessary, cartons would be place to pallets. • Our factory is near to Yantian&Shekou port, Baoan Airport and Hongkong. It takes 45 minutes go to Yantian&Shekou port and Baoan Aiport. It takes about one and half an hour go to Hongkong. It is convenient for tranportation.  09. After-Sales Service We would help you to maintain the moulds in good condition. See more information about our company: Cooperate with real factory for cost saving and high quality. 01. Company Landscape • Cover an area of 3000 Square Meters • 120 Professional staffs with 8 professional engineers in the technical research and development department • Have 20 years rich experience in manufacturing plastic injection mould, plastic parts and silicone rubber keypads.

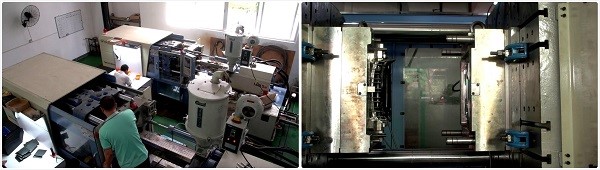

09. After-Sales Service We would help you to maintain the moulds in good condition. See more information about our company: Cooperate with real factory for cost saving and high quality. 01. Company Landscape • Cover an area of 3000 Square Meters • 120 Professional staffs with 8 professional engineers in the technical research and development department • Have 20 years rich experience in manufacturing plastic injection mould, plastic parts and silicone rubber keypads.  02. Workshop • Advanced equipments for mould making, CNC machines, Milling machines, Grinding Machines, EDM machines etc. • Injection molding machines range from 80 to 300 tons

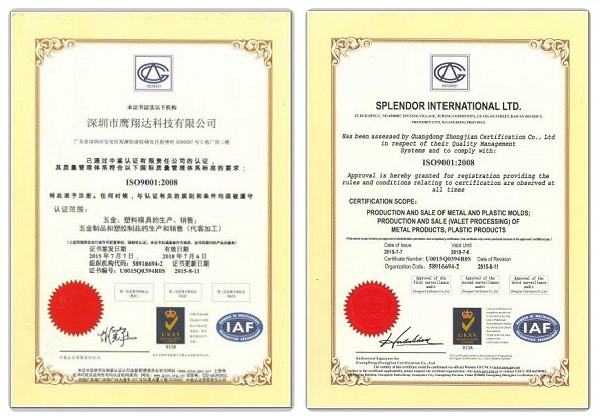

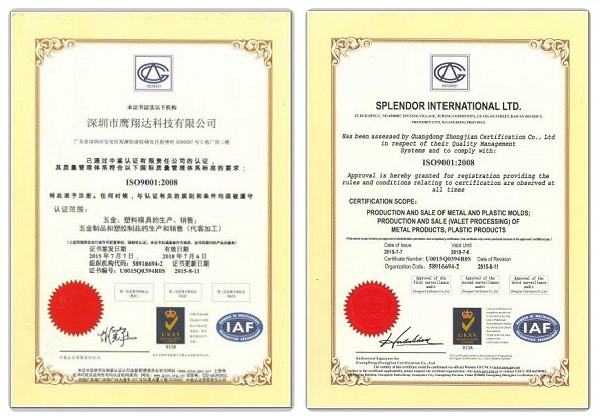

02. Workshop • Advanced equipments for mould making, CNC machines, Milling machines, Grinding Machines, EDM machines etc. • Injection molding machines range from 80 to 300 tons  03. Quality Management: Certificated by ISO9001:2008 • There are 2 QC Managers to head the Quality Control Fuction. • Quality Manuual for workers to keep high quality in mind • There is developed quality control plan showing inspection procedures used during manufacturing

03. Quality Management: Certificated by ISO9001:2008 • There are 2 QC Managers to head the Quality Control Fuction. • Quality Manuual for workers to keep high quality in mind • There is developed quality control plan showing inspection procedures used during manufacturing  04.Warehouse and Emergency Facilities • Raw material are kept in controlled, segregated locations to prevent quality deterioration. Master cartons are placed to pallets to avoid damage and contamination • Raw material and finished products warehouse are clearly isolated from production areas. • Fire Extinguishers and fire alarms are installed in each working section. • Emergency lights & Exit signs installed at all emergency exits.

04.Warehouse and Emergency Facilities • Raw material are kept in controlled, segregated locations to prevent quality deterioration. Master cartons are placed to pallets to avoid damage and contamination • Raw material and finished products warehouse are clearly isolated from production areas. • Fire Extinguishers and fire alarms are installed in each working section. • Emergency lights & Exit signs installed at all emergency exits.  05. Our Customers: Our Splendor have lots of customers in USA, UK, Russia, Turkey, New Zealand, Greece, Denmark, Italy, Israel, Australia etc. As our customers are satisfied with our high quality, competitive price, superior service and punctual delivery, we have gained good reputation from them.

05. Our Customers: Our Splendor have lots of customers in USA, UK, Russia, Turkey, New Zealand, Greece, Denmark, Italy, Israel, Australia etc. As our customers are satisfied with our high quality, competitive price, superior service and punctual delivery, we have gained good reputation from them.  06. Exhibition: Mould Eurasia 2012 in Turkey; Rosmould 2013 & 2014 & 2015 in Russia; NPE 2015 in Florida, USA

06. Exhibition: Mould Eurasia 2012 in Turkey; Rosmould 2013 & 2014 & 2015 in Russia; NPE 2015 in Florida, USA

02. Design 3D Mould Drawing • Our Engineer will design 3D mould drawing for your confirmation. • Design Software: Pro-E, Iges, UG, CAD etc • Mould Base Material: LKM, HASKCO, LOCAL, DME etc • Mould Core Material: 718H, S136H, NAK80, P20 ect • Mould Cavity: Single & Multi Cavity • Runner: Cold or Hot Runner • Gate: Pinpoint Gate or Edge Gate • Finish: Polish or Semi-matt

02. Design 3D Mould Drawing • Our Engineer will design 3D mould drawing for your confirmation. • Design Software: Pro-E, Iges, UG, CAD etc • Mould Base Material: LKM, HASKCO, LOCAL, DME etc • Mould Core Material: 718H, S136H, NAK80, P20 ect • Mould Cavity: Single & Multi Cavity • Runner: Cold or Hot Runner • Gate: Pinpoint Gate or Edge Gate • Finish: Polish or Semi-matt  03. Injection Plastic Moulding Making • Main Processing Equipment: CNC Machines, Milling Machines, Grinding Machine, EDM etc. • 15-45 days for mould making and first sampples.

03. Injection Plastic Moulding Making • Main Processing Equipment: CNC Machines, Milling Machines, Grinding Machine, EDM etc. • 15-45 days for mould making and first sampples.  04. Trial Mould

04. Trial Mould  05. Test Samples

05. Test Samples  06. Mass Production after customer confirmed samples. • Material Reception, Incoming Quality Check(IQC) Records, Production Quality Check(PQC) records and Final Inspection(FI) records are availiable. • There are work instructions for workers to follow it to perform their work and regular QC Inspections on products during manufacturing. • There is approval samples attached to working stations and production lines for reference where appropriate. Non-conforming products properly segregated and clearly identified. • 7-20 days for mass production.

06. Mass Production after customer confirmed samples. • Material Reception, Incoming Quality Check(IQC) Records, Production Quality Check(PQC) records and Final Inspection(FI) records are availiable. • There are work instructions for workers to follow it to perform their work and regular QC Inspections on products during manufacturing. • There is approval samples attached to working stations and production lines for reference where appropriate. Non-conforming products properly segregated and clearly identified. • 7-20 days for mass production.  07. Second Processing: Silk-Screen Printing, Painting, Ultrasound, Assembly and so on.

07. Second Processing: Silk-Screen Printing, Painting, Ultrasound, Assembly and so on.  08. Package and Shipment • Wooden case for Plastic Injection Mould • Inner package for plastic injection products: 1pcs/polybag. Carton box for out package. If necessary, cartons would be place to pallets. • Our factory is near to Yantian&Shekou port, Baoan Airport and Hongkong. It takes 45 minutes go to Yantian&Shekou port and Baoan Aiport. It takes about one and half an hour go to Hongkong. It is convenient for tranportation.

08. Package and Shipment • Wooden case for Plastic Injection Mould • Inner package for plastic injection products: 1pcs/polybag. Carton box for out package. If necessary, cartons would be place to pallets. • Our factory is near to Yantian&Shekou port, Baoan Airport and Hongkong. It takes 45 minutes go to Yantian&Shekou port and Baoan Aiport. It takes about one and half an hour go to Hongkong. It is convenient for tranportation.  09. After-Sales Service We would help you to maintain the moulds in good condition. See more information about our company: Cooperate with real factory for cost saving and high quality. 01. Company Landscape • Cover an area of 3000 Square Meters • 120 Professional staffs with 8 professional engineers in the technical research and development department • Have 20 years rich experience in manufacturing plastic injection mould, plastic parts and silicone rubber keypads.

09. After-Sales Service We would help you to maintain the moulds in good condition. See more information about our company: Cooperate with real factory for cost saving and high quality. 01. Company Landscape • Cover an area of 3000 Square Meters • 120 Professional staffs with 8 professional engineers in the technical research and development department • Have 20 years rich experience in manufacturing plastic injection mould, plastic parts and silicone rubber keypads.  02. Workshop • Advanced equipments for mould making, CNC machines, Milling machines, Grinding Machines, EDM machines etc. • Injection molding machines range from 80 to 300 tons

02. Workshop • Advanced equipments for mould making, CNC machines, Milling machines, Grinding Machines, EDM machines etc. • Injection molding machines range from 80 to 300 tons  03. Quality Management: Certificated by ISO9001:2008 • There are 2 QC Managers to head the Quality Control Fuction. • Quality Manuual for workers to keep high quality in mind • There is developed quality control plan showing inspection procedures used during manufacturing

03. Quality Management: Certificated by ISO9001:2008 • There are 2 QC Managers to head the Quality Control Fuction. • Quality Manuual for workers to keep high quality in mind • There is developed quality control plan showing inspection procedures used during manufacturing  04.Warehouse and Emergency Facilities • Raw material are kept in controlled, segregated locations to prevent quality deterioration. Master cartons are placed to pallets to avoid damage and contamination • Raw material and finished products warehouse are clearly isolated from production areas. • Fire Extinguishers and fire alarms are installed in each working section. • Emergency lights & Exit signs installed at all emergency exits.

04.Warehouse and Emergency Facilities • Raw material are kept in controlled, segregated locations to prevent quality deterioration. Master cartons are placed to pallets to avoid damage and contamination • Raw material and finished products warehouse are clearly isolated from production areas. • Fire Extinguishers and fire alarms are installed in each working section. • Emergency lights & Exit signs installed at all emergency exits.  05. Our Customers: Our Splendor have lots of customers in USA, UK, Russia, Turkey, New Zealand, Greece, Denmark, Italy, Israel, Australia etc. As our customers are satisfied with our high quality, competitive price, superior service and punctual delivery, we have gained good reputation from them.

05. Our Customers: Our Splendor have lots of customers in USA, UK, Russia, Turkey, New Zealand, Greece, Denmark, Italy, Israel, Australia etc. As our customers are satisfied with our high quality, competitive price, superior service and punctual delivery, we have gained good reputation from them.  06. Exhibition: Mould Eurasia 2012 in Turkey; Rosmould 2013 & 2014 & 2015 in Russia; NPE 2015 in Florida, USA

06. Exhibition: Mould Eurasia 2012 in Turkey; Rosmould 2013 & 2014 & 2015 in Russia; NPE 2015 in Florida, USA

Related Keywords

Related Keywords