Custom plastic injection molding/tooling service

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

General Information of plastic injection mould:

Follow us to visit our facotry: Cooperation with direct manufacturer for cost saving and high qulity: 01. Company Landscape  02. Manufacturing Process

02. Manufacturing Process  03. Warehouse

03. Warehouse  04. Workshop:

04. Workshop:

05.Final Inspection and QA Testing

05.Final Inspection and QA Testing  06. Quality Management:

06. Quality Management:  07. Exhibition: ROSMOULD 2013&2014 in Russia

07. Exhibition: ROSMOULD 2013&2014 in Russia  Why Choose our Splendor? • We have a technical research and development department with 6 professional engineers, which can provide customers with engineering and technical design support in mold and product design. • With 20 years experience, we have strict process to control the quality and time to produce, which can offer you high quality and punctual delivery time. • We are the factory to make mold and molded parts, which help our customer to save money. As you know, there is no lowest price, only reasonable price. • We can perform secondary operations, such as assembly, printing, painting and decoratin when needed. • Our plant and equipment is current with 15 molding machines ranging from 80 to 300 tons. • We have gained great reputaton and trust from our customers. • We provide one-stop service from plastic injection mould design -- injection mould 3D drawing -- tooling --manufacture for injection mould -- processing -- surface treatment -- packing with our inmate colleagues. • Our passion team are flexible and friendly. We will participate in NPE 2015 THE INTERNATIONAL PLASTICS SHOWCASE

Why Choose our Splendor? • We have a technical research and development department with 6 professional engineers, which can provide customers with engineering and technical design support in mold and product design. • With 20 years experience, we have strict process to control the quality and time to produce, which can offer you high quality and punctual delivery time. • We are the factory to make mold and molded parts, which help our customer to save money. As you know, there is no lowest price, only reasonable price. • We can perform secondary operations, such as assembly, printing, painting and decoratin when needed. • Our plant and equipment is current with 15 molding machines ranging from 80 to 300 tons. • We have gained great reputaton and trust from our customers. • We provide one-stop service from plastic injection mould design -- injection mould 3D drawing -- tooling --manufacture for injection mould -- processing -- surface treatment -- packing with our inmate colleagues. • Our passion team are flexible and friendly. We will participate in NPE 2015 THE INTERNATIONAL PLASTICS SHOWCASE

| 1 | Mould base material | LKM, HASCO, LOCAL ,DME, etc |

| 2 | Mould core material | 718H, S136H, NAK80 , P20, etc |

| 3 | Plastic molded parts material | ABS, ABS+PC, PC, PP, PVC, |

| 4 | Cavity | Single, Multi |

| 5 | Runner | Hot & Cold Runner |

| 6 | Finish | Semi-Matt, Polish |

| 7 | Design software | Pro-E, IGES, UG, CAD CAXA, ect |

| 8 | Main processing equipment | CNC, Cutting, Carved, Milling, EDM |

| 9 | Arrangement type | I-section, Straight body mould |

| 10 | Second Processing | Silk-scree Printing, Plating, Painting, Polishing, Glossy |

| 11 | Package | Wooden case for mould, carton box for Injection moulding part |

| 12 | Delivery time | 30 days for mould and samples of Injection moulding part, 18 days for mass production. |

| 13 | Trade Term | Ex-works, FOB Shenzhen, CIF |

| 14 | Payment Term | Mould: 50% paid by T/T advance, balance 50% should be paid against the first samples Mass production: Full payment by T/T advance. |

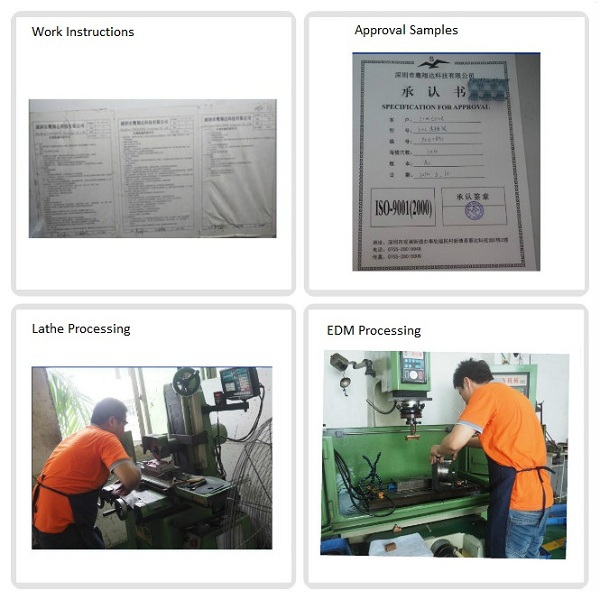

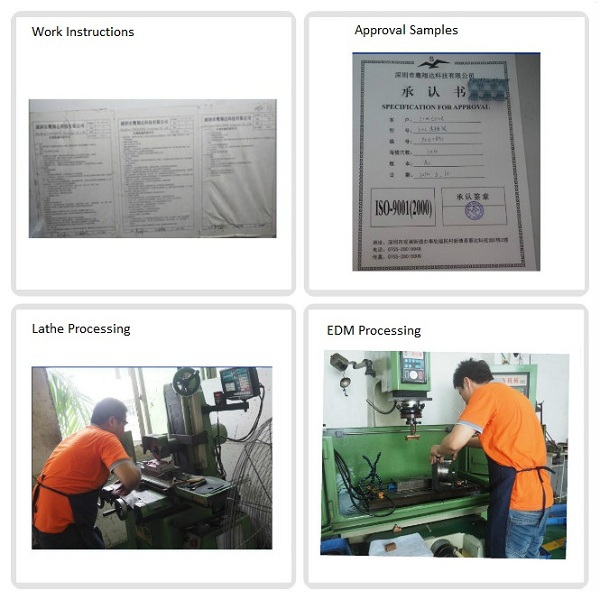

02. Manufacturing Process

02. Manufacturing Process  03. Warehouse

03. Warehouse  04. Workshop:

04. Workshop:

05.Final Inspection and QA Testing

05.Final Inspection and QA Testing  06. Quality Management:

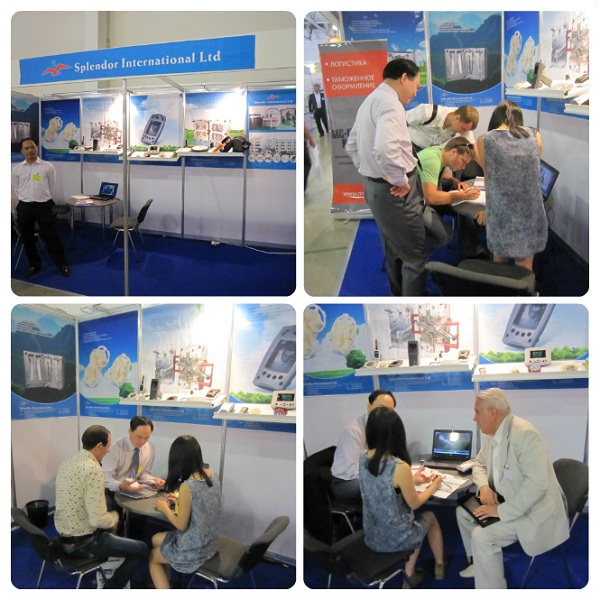

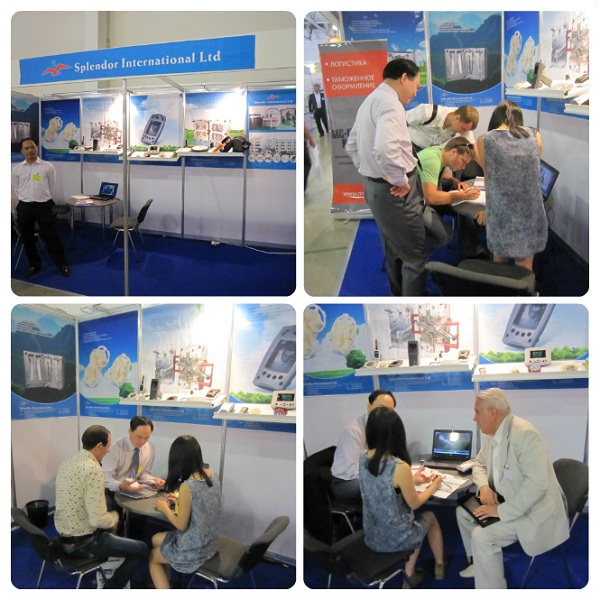

06. Quality Management:  07. Exhibition: ROSMOULD 2013&2014 in Russia

07. Exhibition: ROSMOULD 2013&2014 in Russia  Why Choose our Splendor? • We have a technical research and development department with 6 professional engineers, which can provide customers with engineering and technical design support in mold and product design. • With 20 years experience, we have strict process to control the quality and time to produce, which can offer you high quality and punctual delivery time. • We are the factory to make mold and molded parts, which help our customer to save money. As you know, there is no lowest price, only reasonable price. • We can perform secondary operations, such as assembly, printing, painting and decoratin when needed. • Our plant and equipment is current with 15 molding machines ranging from 80 to 300 tons. • We have gained great reputaton and trust from our customers. • We provide one-stop service from plastic injection mould design -- injection mould 3D drawing -- tooling --manufacture for injection mould -- processing -- surface treatment -- packing with our inmate colleagues. • Our passion team are flexible and friendly. We will participate in NPE 2015 THE INTERNATIONAL PLASTICS SHOWCASE

Why Choose our Splendor? • We have a technical research and development department with 6 professional engineers, which can provide customers with engineering and technical design support in mold and product design. • With 20 years experience, we have strict process to control the quality and time to produce, which can offer you high quality and punctual delivery time. • We are the factory to make mold and molded parts, which help our customer to save money. As you know, there is no lowest price, only reasonable price. • We can perform secondary operations, such as assembly, printing, painting and decoratin when needed. • Our plant and equipment is current with 15 molding machines ranging from 80 to 300 tons. • We have gained great reputaton and trust from our customers. • We provide one-stop service from plastic injection mould design -- injection mould 3D drawing -- tooling --manufacture for injection mould -- processing -- surface treatment -- packing with our inmate colleagues. • Our passion team are flexible and friendly. We will participate in NPE 2015 THE INTERNATIONAL PLASTICS SHOWCASE