Hydraulic Power Source and Trimming Machine Type Metal Casting Products Hydraulic Trimming Machine

- Delivery Time:

- 25 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Specifications Hydraulic Machine for trimming

1.Four columns

2.Fast trimming speed and burr-less trim

3.CE/ISO approved

4.20 years factory

Hydraulic Power Source and Trimming Machine Type Metal Casting Products Hydraulic Trimming Machine

Product features:

1.Precise four-column three-platen frame, the grad of parallelism between the Active platen and the work platform could reach up to more than 0.08mm under the control mode that the three platen are controled by the four precise guide sleeves; schematic diagram: 2.Manual & Semi-automation operation system, front stretched out control platform, emergency buttons, security curtain lights, considerate design for overall security; schematic diagram:

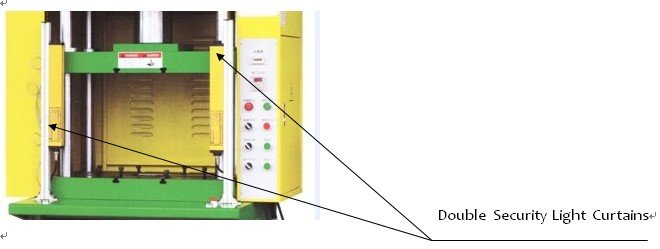

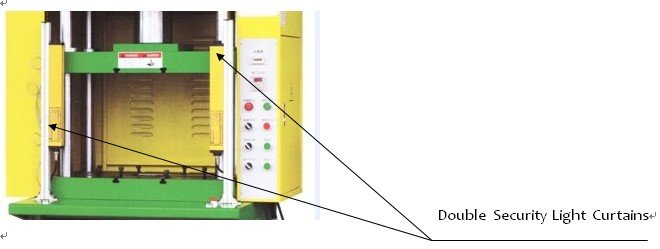

2.Manual & Semi-automation operation system, front stretched out control platform, emergency buttons, security curtain lights, considerate design for overall security; schematic diagram:  3.Instrument of loading material and blow facility, special design concept for special processing work; 4.Pressing force, stroke of cutting, dwell time, die height could be adjusted manually comply with pratical demand; 5.Standard idler wheel and goblet-shaped machine feet, convenient to move. schematic diagram:

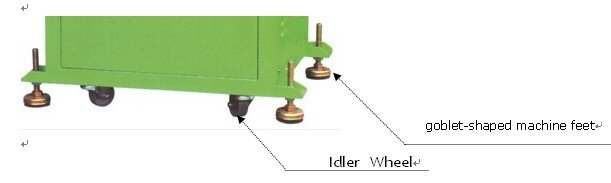

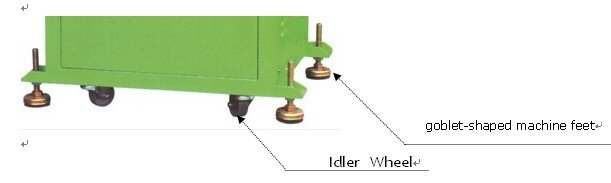

3.Instrument of loading material and blow facility, special design concept for special processing work; 4.Pressing force, stroke of cutting, dwell time, die height could be adjusted manually comply with pratical demand; 5.Standard idler wheel and goblet-shaped machine feet, convenient to move. schematic diagram:  Scope of applications: 1.Die cutitng and shaping of burrs of varioius alloy die casting products;

Scope of applications: 1.Die cutitng and shaping of burrs of varioius alloy die casting products;

2.overall cutitng of plastic products, forming of plastic material, like blanking, stretching and embossing of plates, as well as pressing of plastic and powder products, and other users, It is mostly used in auto and motorcycle fitting sectors. Technical Parameters: (Technical parameter can be customized according to your special need ):

2.overall cutitng of plastic products, forming of plastic material, like blanking, stretching and embossing of plates, as well as pressing of plastic and powder products, and other users, It is mostly used in auto and motorcycle fitting sectors. Technical Parameters: (Technical parameter can be customized according to your special need ):

More product images:

1.Four columns

2.Fast trimming speed and burr-less trim

3.CE/ISO approved

4.20 years factory

Hydraulic Power Source and Trimming Machine Type Metal Casting Products Hydraulic Trimming Machine

Product features:

1.Precise four-column three-platen frame, the grad of parallelism between the Active platen and the work platform could reach up to more than 0.08mm under the control mode that the three platen are controled by the four precise guide sleeves; schematic diagram:

2.Manual & Semi-automation operation system, front stretched out control platform, emergency buttons, security curtain lights, considerate design for overall security; schematic diagram:

2.Manual & Semi-automation operation system, front stretched out control platform, emergency buttons, security curtain lights, considerate design for overall security; schematic diagram:  3.Instrument of loading material and blow facility, special design concept for special processing work; 4.Pressing force, stroke of cutting, dwell time, die height could be adjusted manually comply with pratical demand; 5.Standard idler wheel and goblet-shaped machine feet, convenient to move. schematic diagram:

3.Instrument of loading material and blow facility, special design concept for special processing work; 4.Pressing force, stroke of cutting, dwell time, die height could be adjusted manually comply with pratical demand; 5.Standard idler wheel and goblet-shaped machine feet, convenient to move. schematic diagram:  Scope of applications: 1.Die cutitng and shaping of burrs of varioius alloy die casting products;

Scope of applications: 1.Die cutitng and shaping of burrs of varioius alloy die casting products;

2.overall cutitng of plastic products, forming of plastic material, like blanking, stretching and embossing of plates, as well as pressing of plastic and powder products, and other users, It is mostly used in auto and motorcycle fitting sectors. Technical Parameters: (Technical parameter can be customized according to your special need ):

2.overall cutitng of plastic products, forming of plastic material, like blanking, stretching and embossing of plates, as well as pressing of plastic and powder products, and other users, It is mostly used in auto and motorcycle fitting sectors. Technical Parameters: (Technical parameter can be customized according to your special need ): | Model

| XTM106K-10 | XTM106K-20 | XTM106K-30 | XTM106K-40 | XTM106K-50 | XTM106K-60 | ||

| Nominal Force

| 10T | 20T | 30T | 40T | 50T | 60T | ||

| Max. Hydraulic Working Pressure | 8MPa | 16MPa | 17Mpa | 15.5MPa | 15.6MPa | 15.5MPa | ||

| Knock-out Force

| 7.6T | 3T | 3.9T | 4.3T | 4.8T | 5.3T | ||

| Worktable Height

| 780mm | 780mm | 780mm | 780mm | 780mm | 780mm | ||

Max. Operational Height | 400mm | 400mm | 500mm | 500mm | 500mm | 500mm | ||

| Max. Stroke

| 200mm | 300mm | 300mm | 300mm | 300mm | 300mm | ||

| Dimensions of the Table | L-R

| 500mm | 500mm | 500mm | 600mm | 600mm | 600mm | |

| F-B

| 400mm | 400mm | 400mm | 500mm | 500mm | 500mm | ||

| Speed of Slide | Descending Speed | ≥ 120mm/s | ≥142mm/s | ≥140mm/s | ≥142mm/s | ≥142mm/s | ≥150mm/s | |

| Pressing Speed | ≥19mm/s | ≥16mm/s | ≥12mm/s | ≥9mm/s | ≥7mm/s | ≥7mm/s | ||

| Returning Speed | ≥100mm/s | ≥100mm/s | ≥100mm/s | ≥82mm/s | ≥74mm/s | ≥85mm/s | ||

| Overall Size of the Machine | 700×600×1920(mm) | 700×600×2050(mm) | 700×600×2250(mm) | 700×600×2500(mm) | 700×600×2550(mm) | 700×600×2600(mm) | ||

| Power of Motor

| 3.75KW | 2.2KW | 3.7KW | 3.7KW | 5.5KW | 5.5KW | ||

More product images:

Related Keywords

Related Keywords

You May Also Like

You May Also Like