Highly Precision Servo Press, PCB Press Fit Servo Press

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Highly Precision Servo Press, PCB Press Fit Servo Press Product Description Features of servo press 1. Servo motor driven high-precision ball screw for precision assembly work.

2. Precise closed-loop control of pressure and displacement .

3. Entire process graphs of Press-fit force and displacement can be displayed on the LCD touch screen.

4. Automatically determines the eligibility of product in any stage of the press process,100% removes defective products in real time, enabling online quality control.

5. All technical data (pressure,displacement,press speed ,dwell time) can be set via frendly man-machine interface,easy to operate.

6. 100 of different kinds of press-fit programe can be stored.

7. Seven kinds of press-fit models to choose to meet the requirements of different processes.

8. Simply callout the different mounting program to meet the process of different specification product, easily implement a multifunctional and flexible set of lines.

Highlight of high precision servo presses 1.Compared to the traditional pneumatic press and hydraulic presses, more than 80% of energy-saving , more environmentally friendly and safe, can meet the requirements of clean room equipment.

Highlight of high precision servo presses 1.Compared to the traditional pneumatic press and hydraulic presses, more than 80% of energy-saving , more environmentally friendly and safe, can meet the requirements of clean room equipment.

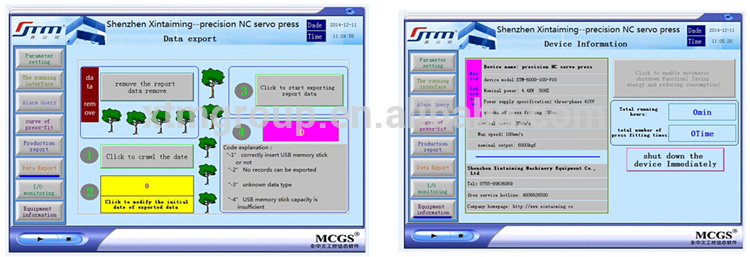

2.Connected to your computer through the external ports, press-fit data can be stored on your computer, ensure that the processing data can be traced back, ease of production and quality management control.

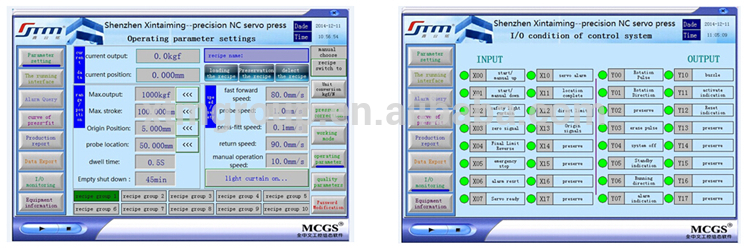

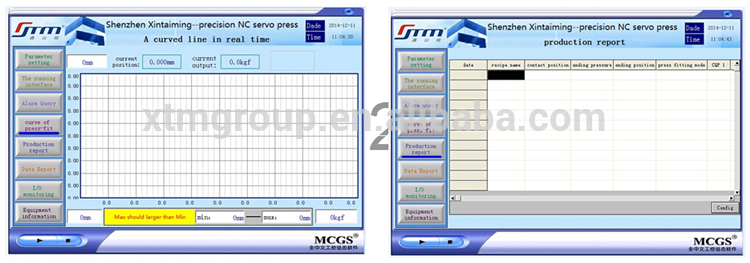

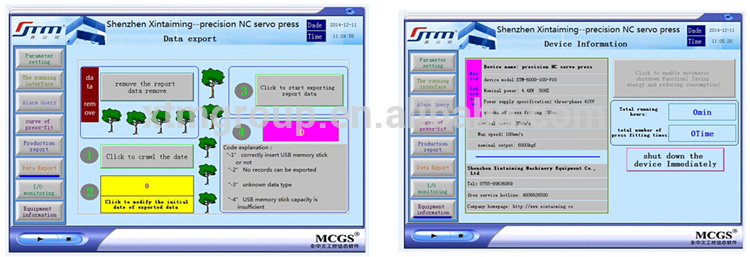

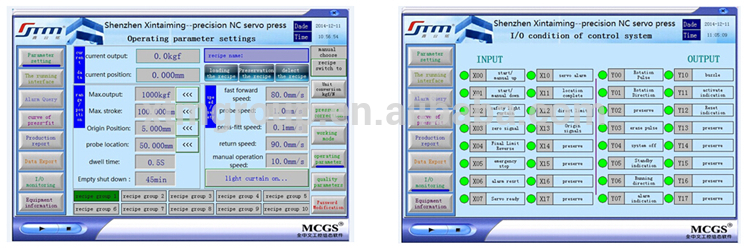

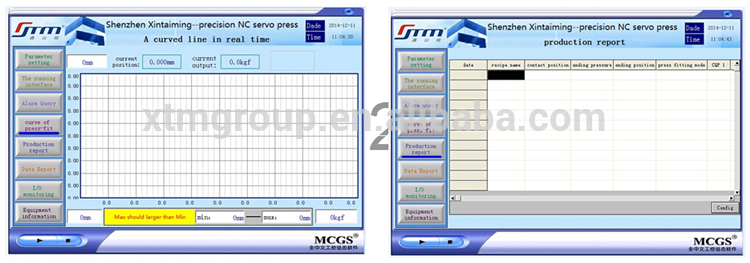

Functions of human-computer interface The functions and working interfaces which can be fast switched of the color touch screen controller are as below: parameter setting monitoring of I/O

parameter setting monitoring of I/O  current curve production report

current curve production report  data eport decive information Technical Parameter

data eport decive information Technical Parameter

High Precision Servo Presses For Precision Assembly Work,customer made's available.

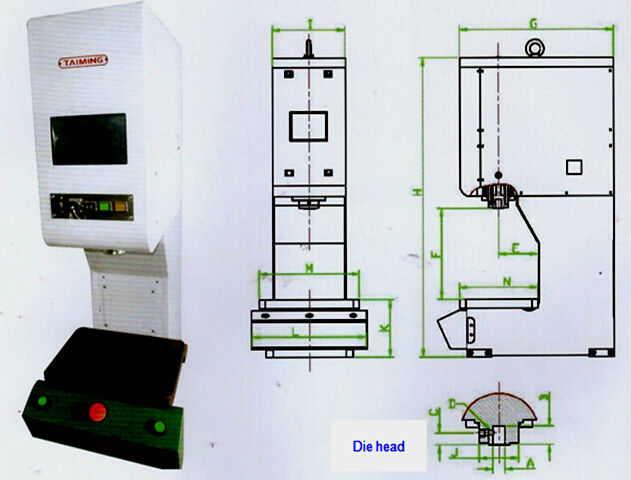

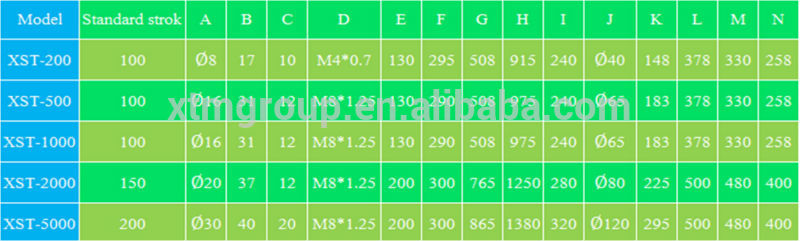

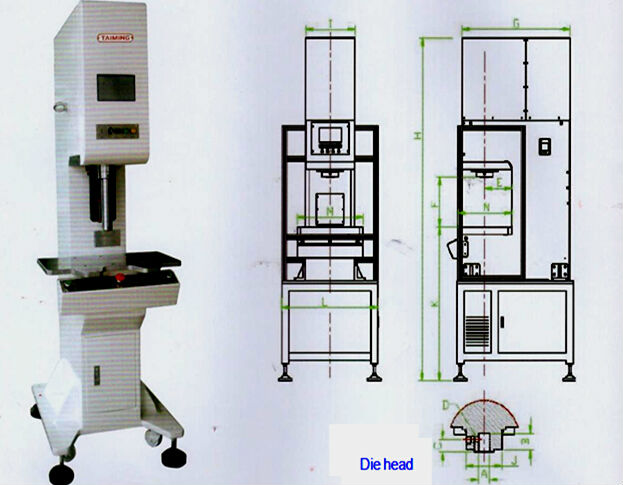

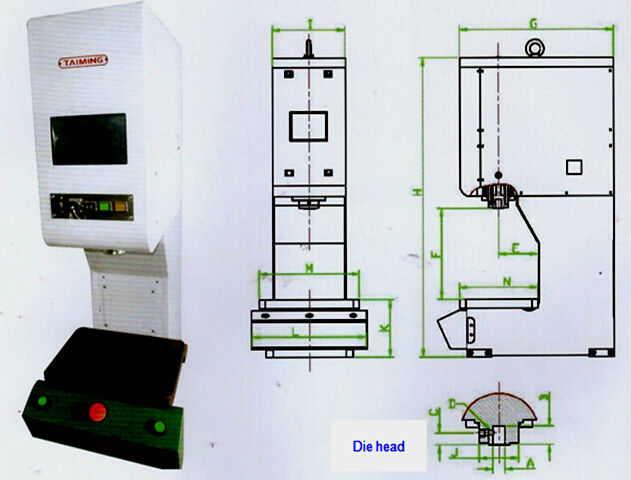

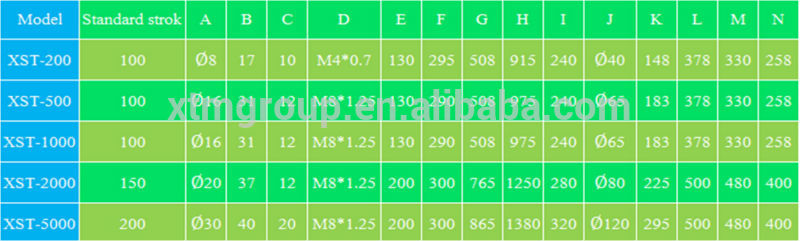

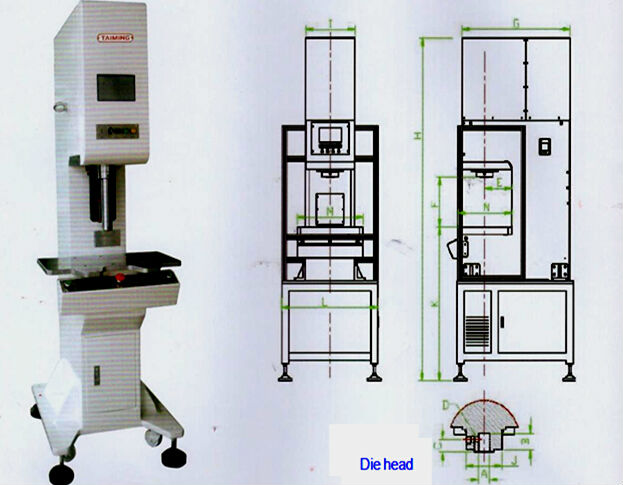

Dimension Dimension of precision servo presses XST desk-type

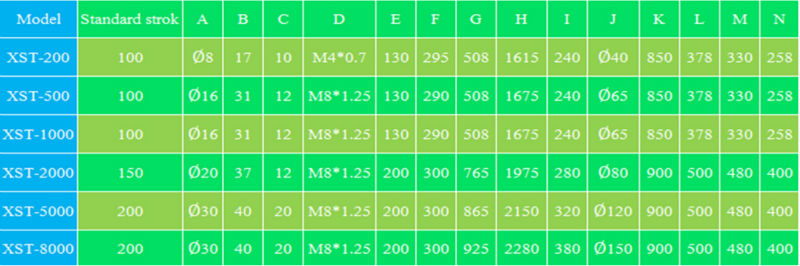

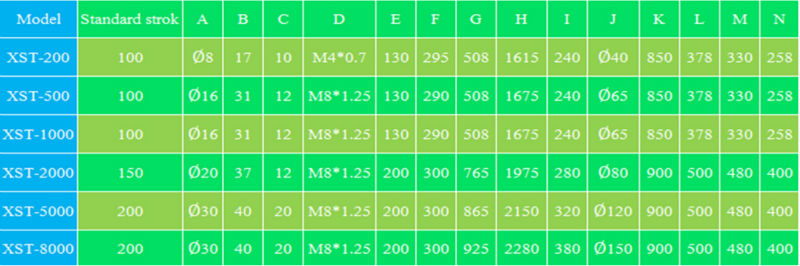

Dimension of precision servo presses XST floor-type

Dimension of precision servo presses XST floor-type

Company Information About Us Shenzhen Xintaiming Machinery Equipment Co., Ltd, professional Hydraulic Press Machine Manufacturer from Shenzhen, China.

Company Information About Us Shenzhen Xintaiming Machinery Equipment Co., Ltd, professional Hydraulic Press Machine Manufacturer from Shenzhen, China.  Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional in designing and making all kinds of hydraulic and pneumatic presses. Servo press CNC hydraulic machines Hydraulic punching machine Hydraulic hot press molding machine High speed trimming machine Hydraulic stamping, embossing machine Hydraulic die cutting machine Hydraulic deep drawing press machine

Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional in designing and making all kinds of hydraulic and pneumatic presses. Servo press CNC hydraulic machines Hydraulic punching machine Hydraulic hot press molding machine High speed trimming machine Hydraulic stamping, embossing machine Hydraulic die cutting machine Hydraulic deep drawing press machine  Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries and regions.

Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries and regions.

Why Choose Us

Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).

Hydraulic press machine are all from first class quality of raw materials.

Specialized workforce (more than 150 employees).

Wide market service network throughout the country.

7500sq meter manufacturing facility, moe than 150 full time employees, X.T.M is fully capable of handling the growing demand worldwide, and offering excellent technology, solid qualit at highly competitive prices for hydraulic press machines.

Our Serive

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performane. Meanwhile, there will be video giving to you (FAT video). 3. Any error happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement. FAQ Q1: Are you a factory or trading company? A: We are a hydraulic press machine factory. Q2: I am wondering if I want to watch video of how the machine perferm, could you send me video? A: You can follow our hydraulic press machine channel on You Tube: https://www.youtube.com/channel/UCCtruSx0tnb6x8n3R5a1HHA .

Q3: Where is your factory located? How can I visit there? A: Our factory is located in E Gong Ling West RD. 6-12, Liu Lian Community, Pingdi Town, Longgang District, Shenzhen China. You can fly to Shenzhen Airport and then take the metro or city bus to our factory. Warmly welcome to visit us! Q4:How does your factory do about quality control? A: We have been CE/ISO certificated and have a complete quality controlling system. We test all the accesories to ensure the quality, and adopt the advanced assembly technology during production and debug before shipping. Q5: What's the payment terms? A:T/T, 40% deposits; 60% balance before deliverying is available

So if you are interested in our hydraulic press machines, please feel no hesitate to contact with us. Warmly welcome YOU to visit our factory!

2. Precise closed-loop control of pressure and displacement .

3. Entire process graphs of Press-fit force and displacement can be displayed on the LCD touch screen.

4. Automatically determines the eligibility of product in any stage of the press process,100% removes defective products in real time, enabling online quality control.

5. All technical data (pressure,displacement,press speed ,dwell time) can be set via frendly man-machine interface,easy to operate.

6. 100 of different kinds of press-fit programe can be stored.

7. Seven kinds of press-fit models to choose to meet the requirements of different processes.

8. Simply callout the different mounting program to meet the process of different specification product, easily implement a multifunctional and flexible set of lines.

Highlight of high precision servo presses 1.Compared to the traditional pneumatic press and hydraulic presses, more than 80% of energy-saving , more environmentally friendly and safe, can meet the requirements of clean room equipment.

Highlight of high precision servo presses 1.Compared to the traditional pneumatic press and hydraulic presses, more than 80% of energy-saving , more environmentally friendly and safe, can meet the requirements of clean room equipment.2.Connected to your computer through the external ports, press-fit data can be stored on your computer, ensure that the processing data can be traced back, ease of production and quality management control.

Functions of human-computer interface The functions and working interfaces which can be fast switched of the color touch screen controller are as below:

parameter setting monitoring of I/O

parameter setting monitoring of I/O  current curve production report

current curve production report  data eport decive information Technical Parameter

data eport decive information Technical Parameter High Precision Servo Presses For Precision Assembly Work,customer made's available.

| precise servo press | 200kgf | 500kgf | 1000kgf | 2000kgf | 5000kgf | 8000kgf | |

| work temperature | 0-40°C | ||||||

| Main cylinder stroke | AC220V single phase | AC380 three phase | |||||

| press mode | constant press speed, precise position control | ||||||

| constant press speed, precise pressure control | |||||||

| constant press speed, precise displacement control | |||||||

| press mode | 100 kinds of press mode | ||||||

| human-computer interface | 65536 Colors, 7Inch Touch Screen | ||||||

| control mode | 100Mbps high speed communication module, PLC+exclusive control unit | ||||||

| drive mode | precise AC servo motor, 7 class well ground ball screw | ||||||

| I/O interface | USB2.0, down load & upload available | ||||||

| die connector dia. | ∅ 8mm | ∅ 16mm | ∅ 16mm | ∅ 20mm | ∅ 25mm | ∅ 30mm | |

| pressure output | nominal force | 200kgf | 500kgf | 1000kgf | 2000kgf | 5000kgf | 8000kgf |

| range of application | 10%,100% of the entire stroke | ||||||

| unit | 0.1kgf | ||||||

| pressure precision | 1%F.S | ||||||

| repeat duration | 1‰ F.S | ||||||

| displacement/stroke | standard Stroke | 50/100mm | 150/200/250mm | ||||

| unit | 0.001mm | ||||||

| repeat duration | 0.01mm | ||||||

| linear speed | fast forward | 0.1- -160mm/s | 0.1- -200mm/s | ||||

| detect | 0.1- -20mm/s | 0.1- -30mm/s | |||||

| press | 0.1- -35mm/s | 0.1- -50mm/s | |||||

| return | 0.1- -160mm/s | 0.1- -200mm/s | |||||

| dwell time | Max. | 99.9sec | |||||

| reccomended | <10sec | ||||||

| factory reset | 0.1sec | ||||||

Dimension of precision servo presses XST floor-type

Dimension of precision servo presses XST floor-type

Company Information About Us Shenzhen Xintaiming Machinery Equipment Co., Ltd, professional Hydraulic Press Machine Manufacturer from Shenzhen, China.

Company Information About Us Shenzhen Xintaiming Machinery Equipment Co., Ltd, professional Hydraulic Press Machine Manufacturer from Shenzhen, China.  Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional in designing and making all kinds of hydraulic and pneumatic presses. Servo press CNC hydraulic machines Hydraulic punching machine Hydraulic hot press molding machine High speed trimming machine Hydraulic stamping, embossing machine Hydraulic die cutting machine Hydraulic deep drawing press machine

Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional in designing and making all kinds of hydraulic and pneumatic presses. Servo press CNC hydraulic machines Hydraulic punching machine Hydraulic hot press molding machine High speed trimming machine Hydraulic stamping, embossing machine Hydraulic die cutting machine Hydraulic deep drawing press machine  Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries and regions.

Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries and regions.Why Choose Us

Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).

Hydraulic press machine are all from first class quality of raw materials.

Specialized workforce (more than 150 employees).

Wide market service network throughout the country.

7500sq meter manufacturing facility, moe than 150 full time employees, X.T.M is fully capable of handling the growing demand worldwide, and offering excellent technology, solid qualit at highly competitive prices for hydraulic press machines.

Our Serive

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performane. Meanwhile, there will be video giving to you (FAT video). 3. Any error happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement. FAQ Q1: Are you a factory or trading company? A: We are a hydraulic press machine factory. Q2: I am wondering if I want to watch video of how the machine perferm, could you send me video? A: You can follow our hydraulic press machine channel on You Tube: https://www.youtube.com/channel/UCCtruSx0tnb6x8n3R5a1HHA .

Q3: Where is your factory located? How can I visit there? A: Our factory is located in E Gong Ling West RD. 6-12, Liu Lian Community, Pingdi Town, Longgang District, Shenzhen China. You can fly to Shenzhen Airport and then take the metro or city bus to our factory. Warmly welcome to visit us! Q4:How does your factory do about quality control? A: We have been CE/ISO certificated and have a complete quality controlling system. We test all the accesories to ensure the quality, and adopt the advanced assembly technology during production and debug before shipping. Q5: What's the payment terms? A:T/T, 40% deposits; 60% balance before deliverying is available

So if you are interested in our hydraulic press machines, please feel no hesitate to contact with us. Warmly welcome YOU to visit our factory!

Related Keywords

Related Keywords

You May Also Like

You May Also Like