Four Column Double Action Deep Drawing Hydraulic Press For Aluminum Utensils Machinery

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

Equipped With Hydraulic Blank Holder And Automatic Knock-Out Device

For Aluminum Utensils

CE/ISO

Four Column Double Action Deep Drawing Hydraulic Press For Aluminum Utensils Machinery

Product Description

Four column double action deep drawing hydraulic press is a new type CNC control deep drawing hydraulic press for aluminum utensils machinery.

PLC computer control: full touch screen, precise programmed process control ;

The main cylinder and lower cylinder are provided with pressure proportioning function;

Flexibly adjustable pressure and stroke;

Machine dwell time and stroke could be set specially as per processing requirements;

Idea of doubled SLC (Security Light Curtain) makes it safer of operation;

Protective fence and the safety interlock can be added to upgrade the secure;

Adopts advanced cartridge valve blocks technology ,piping and oil leaks reduced;

All pipes, flange and joint with vibrations proof and leakage proof design and setting.

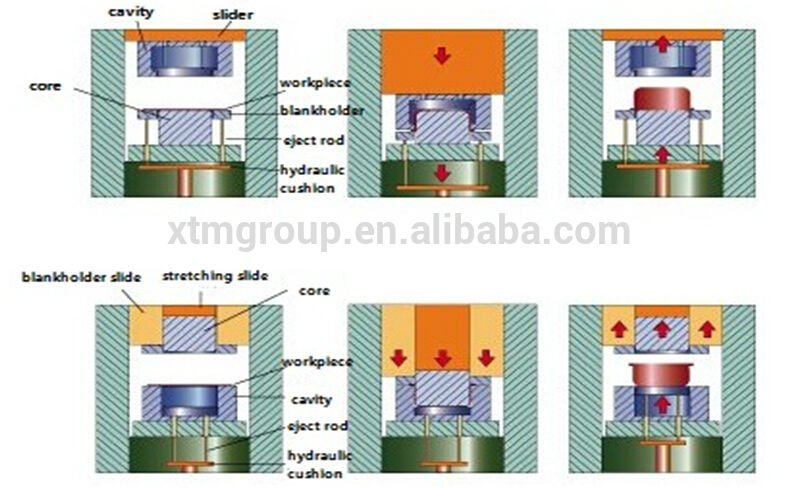

Deep Drawing steps of deep drawing machine

| Highlight of YD65B double action deep drawing hydraulic press 1. PLC computer can store technical data of different drawing die so as to reduce repeat adjustment of pre-work when similar products are made, improve production efficiency.

|

Detailed pictures of double action deep drawing hydraulic press for aluminum utensils machinery

overall vew:

control parts (stroke limit switch, pressure regulator, control panel):

control panel and hydraulic unit

electric control circuit

Technical Parameter

| Model | Unit | YD65B-120 | YD65B-150 | YD65B-200 | YD65B-250 | YD65B-350 | |

| Main cylinder force | KN | 800 | 1000 | 1500 | 1700 | 2300 | |

| Max. pressure of main cylinder liquid | MPa | 22 | 21 | 20 | 21 | 17 | |

| Main cylinder stroke | mm | 550 | 550 | 550 | 550 | 650 | |

| Low cylinder force | KN | 400 | 600 | 700 | 800 | 1200 | |

| Low cylinder stroke | mm | 200 | 250 | 250 | 300 | 300 | |

| Max. pressure of lower cylinder liquid | PMa | 20 | 20 | 19 | 22 | 20 | |

| Stroke of knock-out | mm | 200 | 250 | 250 | 250 | 300 | |

|

Daylight opening

| Max. |

mm | 850 | 850 | 920 | 920 | 1100 |

| Min. | 300 | 300 | 370 | 370 | 450 | ||

|

dimension of table | L-R |

mm | 600 | 600 | 750 | 850 | 950 |

| F-B | 600 | 750 | 850 | 880 | 1000 | ||

Speed of slide | closing |

mm/s | 230 | 230 | 230 | 220 | 190 |

| press | 27-70 adjustable | 27-65 adjustable | 30-60 adjustable | 20-53 adjustable | 20-50 adjustable | ||

| return | 245 | 255 | 205 | 205 | 190 | ||

| Rise speed of lower cylinder | mm/s | 95 | 80 | 90 | 90 | 80 | |

| Height of workingtable above floor | mm | 1150 | 1180 | 1220 | 1250 | 1470 | |

Overall dimension | L-R | mm | 1840 | 2050 | 2130 | 2230 | 2270 |

| F-B | 1220 | 1510 | 1620 | 1650 | 1810 | ||

| H | 3210 | 3480 | 3590 | 3680 | 4300 | ||

| Motor power | KW | 15 | 18.5 | 30 | 30 | 37 | |

| Weight | T | 4.5 | 6.7 | 8.1 | 8.9 | 13.8 | |

Note: the specifications of the double action deep drawing hydraulic press for aluminum utensils machinery are customization supported. Scope of Application YD65B series of dopuble action deep drawing hydraulic press is specially developed for pressing aluminum utensils products and stainless steel products, especially suitable for

stretching aluminum sheets,pressing and forming aluminum and stainless steel products.

| About Us |

all kinds of hydraulic and pneumatic presses. 1) CNC Servo press series 2) CNC hydraulic machines 3) MD/IML 3D punching machine 4) IMD/IML hot press molding machine 5) High speed punching machine 6) Hydraulic stamping/embossing/cutting /drawing press machine and so on Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than

30 countries and regions.

| Why Choose Us |

Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).

First class quality of raw materials.

Specialized workforce (more than 150 employees).

Wide market service network throughout the country.

7500sq meter manufacturing facility, moe than 150 full time employees, X.T.M is fully capable of

handling the growing demand worldwide, and offering excellent technology, solid qualit at highly competitive prices.

| Our Serive |

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron

etc. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and

electrical parts performane. Meanwhile, there will be video giving to you (FAT video). 3. Any error(not man-made)happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

| Other Products |

| FAQ |

Strong research and development ability, powerful marketing ability, commitment, expertise and dedication. When it comes to hydraulic / pneumatic based press machines, Please feel no

hesitateto contact with X.T.M.

Related Keywords