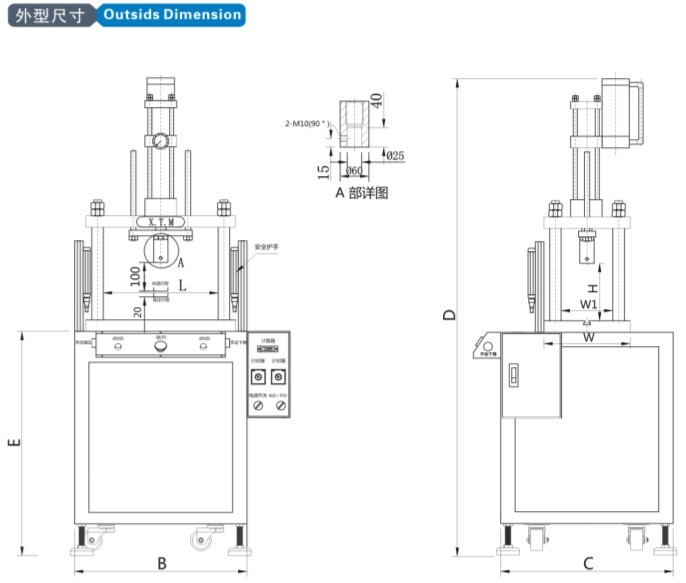

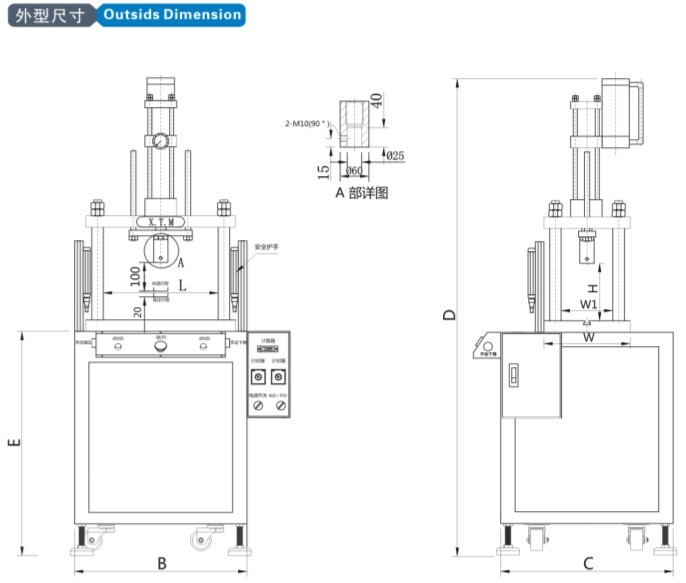

XTM-102-10T series Booster presses machine

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

XTM-102 series power presses

The series press with compressed air as the power source, simple operation; standby of the oil hydraulic system, there is no noise, which can reduce power consumption to reduce the production cost; the empty oil pressurizing principle, achieves the movement speed, high output; output force, speed, stroke, shut height, Paul pressure time five parameters can be adjusted, and with automatic counting function is ideal processing equipment for the user. Products with advanced technology, reasonable structure, no vibration, no noise, no pollution, high processing quality advantages.

Scope of application:

Widely used in electronic and electrical appliances, instrumentation, horologe, thermostat / relay, automobile and motorcycle accessories, micro electrical and mechanical equipment, hardware industry production and assembly.

Power presses | power presses | power presses | power presses | power presses | power presses | principle.

By using the high pressure gas produced by the compressor, the compressed gas is conveyed to the electromagnetic valve through a pipeline, and the action of the solenoid valve is controlled by a pedal switch to control the working and the return of the cylinder. The compressed air can be stored in the storage tank, ready to use, so the motor did not idle waste of energy. Using the cylinder as the working component and using the electromagnetic valve as the control element, the machine structure is simple, the failure rate is low, the maintenance is simple, and the maintenance cost is lower. 220V power supply to achieve the control of the solenoid valve, easy to operate.

The scope of application of the press | booster press | booster press | booster press | booster press | booster press | booster: this series of gas dynamic press are widely used for the industries of electronics, home appliances, printing, packaging, plastics, furniture, cars and other small parts of pressure, molding, assembly and riveting, printing, punching, cutting, bending, stamping, printing and other light load precision requirements. (such as: motor group, axis, the bearings pressed into the transformer molding, electrical switch group, electronics, computer parts group, riveting, photo frame molding, plastic molding, cut, trademark printing, typing and so on).

Applicable scope: (power presses, gas-liquid booster machine, pneumatic pressing machine, gas-liquid riveting machine, oil press).

This series of booster press is widely applicable to various materials of punching, stamping, plastic, bending, shear, tensile, riveting, and electronic and electrical appliances, instrumentation, watch components, thermostat / relay, hardware and other industries in the production and assembly; can conveniently and effectively replace hydraulic equipment of many functions. With compressed air plant preferred products.

Product features:

1. The series press only to 0.2-1mpa compressed air as the power source, can produce the 1-40 tons of force, the external AC220V AC power. The total power consumption does not exceed 20W.

2 as a result of using the gas-liquid booster cylinder, the rapid and flexible pneumatic working system and the stability of the hydraulic system, no impact, no noise, to a large extent, improve the quality of the workpiece, and the life of the mold.

3 continuous pressure or stop, unlike the pure hydraulic system motor to operate continuously, can save energy.

4 output stroke by a certain limit, generally not more than 20MM, but the output is stable, can be a constant output constant.

5 cylinder down speed can be adjusted, the cylinder stroke, working area, opening height can be customized according to customer requirements.

6 only need to adjust the pressure regulator valve can achieve the required pressure loading, simple and convenient.

7 with automatic counting function, but also with force measuring display, intelligent temperature control instrument customized according to customer requirements.

The 8 series of press pressing stroke by a pressure switch, position sensor, or the customers own mold control.

9 manual and semi automatic control mode of the two, equipped with emergency recovery button, can also install infrared hand device.

The 10 series power range 3tf. 5tf. press 10tf. 15tf. 20tf. 25tf. 30tf. 40tf. (1tf=1000kgf=9.8KN).

The series press with compressed air as the power source, simple operation; standby of the oil hydraulic system, there is no noise, which can reduce power consumption to reduce the production cost; the empty oil pressurizing principle, achieves the movement speed, high output; output force, speed, stroke, shut height, Paul pressure time five parameters can be adjusted, and with automatic counting function is ideal processing equipment for the user. Products with advanced technology, reasonable structure, no vibration, no noise, no pollution, high processing quality advantages.

Scope of application:

Widely used in electronic and electrical appliances, instrumentation, horologe, thermostat / relay, automobile and motorcycle accessories, micro electrical and mechanical equipment, hardware industry production and assembly.

Power presses | power presses | power presses | power presses | power presses | power presses | principle.

By using the high pressure gas produced by the compressor, the compressed gas is conveyed to the electromagnetic valve through a pipeline, and the action of the solenoid valve is controlled by a pedal switch to control the working and the return of the cylinder. The compressed air can be stored in the storage tank, ready to use, so the motor did not idle waste of energy. Using the cylinder as the working component and using the electromagnetic valve as the control element, the machine structure is simple, the failure rate is low, the maintenance is simple, and the maintenance cost is lower. 220V power supply to achieve the control of the solenoid valve, easy to operate.

The scope of application of the press | booster press | booster press | booster press | booster press | booster press | booster: this series of gas dynamic press are widely used for the industries of electronics, home appliances, printing, packaging, plastics, furniture, cars and other small parts of pressure, molding, assembly and riveting, printing, punching, cutting, bending, stamping, printing and other light load precision requirements. (such as: motor group, axis, the bearings pressed into the transformer molding, electrical switch group, electronics, computer parts group, riveting, photo frame molding, plastic molding, cut, trademark printing, typing and so on).

Applicable scope: (power presses, gas-liquid booster machine, pneumatic pressing machine, gas-liquid riveting machine, oil press).

This series of booster press is widely applicable to various materials of punching, stamping, plastic, bending, shear, tensile, riveting, and electronic and electrical appliances, instrumentation, watch components, thermostat / relay, hardware and other industries in the production and assembly; can conveniently and effectively replace hydraulic equipment of many functions. With compressed air plant preferred products.

Product features:

1. The series press only to 0.2-1mpa compressed air as the power source, can produce the 1-40 tons of force, the external AC220V AC power. The total power consumption does not exceed 20W.

2 as a result of using the gas-liquid booster cylinder, the rapid and flexible pneumatic working system and the stability of the hydraulic system, no impact, no noise, to a large extent, improve the quality of the workpiece, and the life of the mold.

3 continuous pressure or stop, unlike the pure hydraulic system motor to operate continuously, can save energy.

4 output stroke by a certain limit, generally not more than 20MM, but the output is stable, can be a constant output constant.

5 cylinder down speed can be adjusted, the cylinder stroke, working area, opening height can be customized according to customer requirements.

6 only need to adjust the pressure regulator valve can achieve the required pressure loading, simple and convenient.

7 with automatic counting function, but also with force measuring display, intelligent temperature control instrument customized according to customer requirements.

The 8 series of press pressing stroke by a pressure switch, position sensor, or the customers own mold control.

9 manual and semi automatic control mode of the two, equipped with emergency recovery button, can also install infrared hand device.

The 10 series power range 3tf. 5tf. press 10tf. 15tf. 20tf. 25tf. 30tf. 40tf. (1tf=1000kgf=9.8KN).

Related Keywords

Related Keywords

You May Also Like

You May Also Like