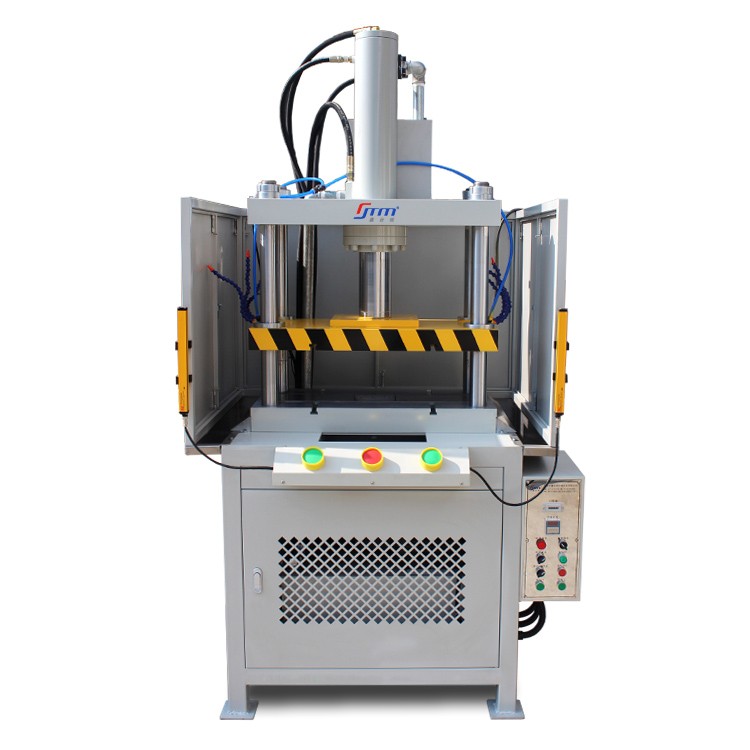

XTM-106K Fast oil pressure machine

- Delivery Time:

- 35 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

XTM-106K fast oil pressure machine

Characteristic

1, adopts four-column.three-plate structure, the active plate paralleling with the working surface in high precision, four precision guided sets so that under the pressure of vertical high precision.

2, safety design, both hands to operate, with emergency button (photoelectric protection device is needed to be additionally mounted) and lower inching adjusting mode button;

3, the work surface with a trough and a blowing device, improve production efficiency;

4, pressure, stroke, speed, dwell time and shut height can be adjusted according to request, convenient operation;

Equipped with casters and foot cup 5, below the table, can be easily moved, labor saving and high efficiency;

Scope of application:

All kinds of aluminum, magnesium alloy die casting products of burr cutting and shaping, whole cutting of plastic products; can also be used in plastic forming materials such as sheet falling material, drawing, stamping and plastic and powder products, pressing and other purposes. The most widely used automobile and motorcycle accessories industry;

XTM106K series fast oil pressure punch

Scope of application: (precision casting products cutting edge machine, precise four column three hydraulic machine, 50 tons of hydraulic punching and cutting machine, 30 tons of fast hydraulic machine, aluminum and magnesium products cutting edge machine, hardware punching machine, key cutting machine)

The series hydraulic machine is all kinds of aluminum, magnesium alloy die casting products of burr cutting and shaping, whole cutting of plastic products; can also be used in plastic forming materials such as sheet of falling material, tensile, TM106 ordinary type of upgrade products, using advanced composite cylinder hydraulic circuit. Both the noise, speed, power consumption, is better than that of ordinary hydraulic press is a high-efficiency and high speed, high output power, high environmental protection of a new generation of hydraulic punching machine this machine is most widely in application of die casting industry.

Product features:

The 1 series hydraulic machine with 2-20MPA liquid pressure as the power source, external three-phase three-phase 50HZ or AC380V

60HZ AC220 AC power supply.

2. The series equipment in liquid as the medium to transmit energy, using advanced composite cylinder hydraulic circuit, low oil temperature, air travel speeds are in 150MM/ seconds or more, industry and trade into the speed of 30 mm / sec following

3 standby equipment, sliding fast moves up and down noise less than 75 dB.

4. Adopts four-column.three-plate structure, the movable plate vertical accuracy by four precise guide set of control, an arbitrary point of the work surface and the working surface of parallel precision achieves 0.1mm below.

5 punch with waste blowing assembly. And at the next table is opened in the center of the waste chute.

6 punch punching under the stop position by a pressure switch, control the position sensor.

. has the function of automatic counting, manual and semi-automatic two control mode, manual can be pressing die stopped at arbitrary distance range, equipped with emergency recovery button, equipped with infrared hand device

8 the pressure, stroke, speed, dwell time and shut height can be adjusted according to request, convenient operation;

9 hydraulic system built at the bottom of the tank, neat appearance, stable.

The 10 series of hydraulic machinery power range 15tf.-200 TF optional. (1tf=1000kgf=9.8KN).

Characteristic

1, adopts four-column.three-plate structure, the active plate paralleling with the working surface in high precision, four precision guided sets so that under the pressure of vertical high precision.

2, safety design, both hands to operate, with emergency button (photoelectric protection device is needed to be additionally mounted) and lower inching adjusting mode button;

3, the work surface with a trough and a blowing device, improve production efficiency;

4, pressure, stroke, speed, dwell time and shut height can be adjusted according to request, convenient operation;

Equipped with casters and foot cup 5, below the table, can be easily moved, labor saving and high efficiency;

Scope of application:

All kinds of aluminum, magnesium alloy die casting products of burr cutting and shaping, whole cutting of plastic products; can also be used in plastic forming materials such as sheet falling material, drawing, stamping and plastic and powder products, pressing and other purposes. The most widely used automobile and motorcycle accessories industry;

XTM106K series fast oil pressure punch

Scope of application: (precision casting products cutting edge machine, precise four column three hydraulic machine, 50 tons of hydraulic punching and cutting machine, 30 tons of fast hydraulic machine, aluminum and magnesium products cutting edge machine, hardware punching machine, key cutting machine)

The series hydraulic machine is all kinds of aluminum, magnesium alloy die casting products of burr cutting and shaping, whole cutting of plastic products; can also be used in plastic forming materials such as sheet of falling material, tensile, TM106 ordinary type of upgrade products, using advanced composite cylinder hydraulic circuit. Both the noise, speed, power consumption, is better than that of ordinary hydraulic press is a high-efficiency and high speed, high output power, high environmental protection of a new generation of hydraulic punching machine this machine is most widely in application of die casting industry.

Product features:

The 1 series hydraulic machine with 2-20MPA liquid pressure as the power source, external three-phase three-phase 50HZ or AC380V

60HZ AC220 AC power supply.

2. The series equipment in liquid as the medium to transmit energy, using advanced composite cylinder hydraulic circuit, low oil temperature, air travel speeds are in 150MM/ seconds or more, industry and trade into the speed of 30 mm / sec following

3 standby equipment, sliding fast moves up and down noise less than 75 dB.

4. Adopts four-column.three-plate structure, the movable plate vertical accuracy by four precise guide set of control, an arbitrary point of the work surface and the working surface of parallel precision achieves 0.1mm below.

5 punch with waste blowing assembly. And at the next table is opened in the center of the waste chute.

6 punch punching under the stop position by a pressure switch, control the position sensor.

. has the function of automatic counting, manual and semi-automatic two control mode, manual can be pressing die stopped at arbitrary distance range, equipped with emergency recovery button, equipped with infrared hand device

8 the pressure, stroke, speed, dwell time and shut height can be adjusted according to request, convenient operation;

9 hydraulic system built at the bottom of the tank, neat appearance, stable.

The 10 series of hydraulic machinery power range 15tf.-200 TF optional. (1tf=1000kgf=9.8KN).

You May Also Like

You May Also Like