High Quality Products Four Column Hydraulic Press Heavy Duty Machine 600T / 1000T for Metal Manufacture

- Delivery Time:

- 15 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

1.High parallel precision,vertical accuracy

2.fast speed, slow pressing

3.self-lubricating

High Quality Products Four Column Hydraulic Press Heavy Duty Machine 600T / 1000T for Metal Manufacture

| Details of Heavy Duty Machine |

| Product Feature | 1. Low energy consumption, high speed and high efficiency. |

2. Two-stage speed control with sliding block, no load high and low speed profiling drawing and high speed back stroke. | |

3. Photoelectric safety protection device ensures safety of operators. | |

| 4. Imported famous and excellent products are adopted for hydraulic elements, electric elements and sealing elements. | |

| Application Scope | 600/1000t hydraulic press heavy duty machine widely used for metal forming industry, especially applicable for: 1. metal shaping 2. metal forming 3. heavy duty metal stamping

|

| Company Advantages | 1. We manufactures the hydraulic and Pneumatic Presses machine and provides |

2. We master the latest hydraulic and control technologies and have 20 years of worldwide manufacturing expertise. | |

3. We have a body of engineers with years of experience. | |

4. Presses can be customized to meet your specific needs and requirements. | |

5. A large-scale factory. |

| About Company |

manufacturer which is specialized in the designing and making all kinds of hydraulic and pneumatic presses. 1)CNC Servo press series 2)CNC C-type hydraulic machine 3)IMD/IML 3D punching machine 4)IMD/IML hot press molding machine 5)Hydraulic cutting /punching/molding/bending/hot press machine 6)XTM series four-column single-acting upper displacement oil press and so on Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam,

the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more

than 30 countries and regions.

| Technical Parameter |

| Model | Unit | YDK-100 | YDK-200 | YDK-300 | YDK-500 | YDK-600 | |

| Cylinder nominal force | KN | 1000 | 2000 | 3000 | 5000 | 6000 | |

| Max. hydraulic pressure | MPa | 19 | 18 | 22 | 22 | 25 | |

| Max. stroke of ram | mm | 200 | 200 | 200 | 200 | 200 | |

|

shut height

| Max. |

mm | 420 | 420 | 420 | 450 | 450 |

| Min. | 220 | 220 | 220 | 250 | 250 | ||

|

dimension of table | L-R |

mm | 450 | 500 | 590 | 650 | 700 |

| F-B | 500 | 550 | 650 | 700 | 750 | ||

|

Speed of slide | moving up |

mm/s | 150 | 150 | 150 | 150 | 150 |

| return | 120 | 120 | 120 | 150 | 150 | ||

Overall size | L-R | mm | 1470 | 1590 | 1715 | 1960 | 2030 |

| F-B | 1150 | 1150 | 1210 | 1210 | 1400 | ||

| H | 2210 | 2260 | 2350 | 2670 | 2780 | ||

Power of motor | KW | 7.5 | 7.5 | 11 | 15 | 15 | |

| Approx. total weight | T | 2.5 | 3.5 | 4 | 6 | 8.5 | |

| Other Product Picture |

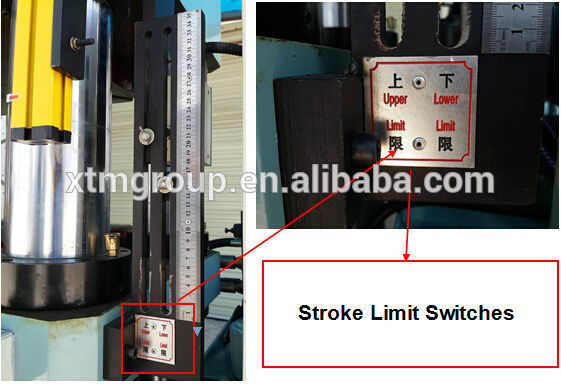

detailed pictures of the metal stamping machine:

detailed pictures of the metal stamping machine:

| Factory Overview |

| XTM Workshop&Warehouse |

| XTM in Exhibitions |

| Clients' Visit to XTM |

| Certification |

| Other Products |

| FAQ |

Q1: Are you a factory or trading company? A: We are a factory. Q2: Where is your factory located? How can I visit there? A: Our factory is located in E Gong Ling West RD. 6-12, Liu Lian Community, Pingdi Town, Longgang District, Shenzhen China. You can fly to Shenzhen Airport and then take the metro or city bus to our factory. Warmly welcome to visit us! Q3:How does your factory do about quality control? A: We have been CE/ISO certificated and have a complete quality controlling system. We test all the accesories to ensure the quality, and adopt the advanced assembly technology during production and debug before shipping. Q4: What's the payment terms? A:T/T, 40% deposits; 60% balance before deliverying is available

Related Keywords