H frame Up Stroke Type Hydraulic Press for Metal Manufacturing With CE / ISO

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Specifications H Frame Four Column With Ejection Function;

Capacity:100 Ton to 1000 Ton;

Easily Adjust The Pressure Via Pressure Regulater;

H frame Up Stroke Type Hydraulic Press for Metal Manufacturing With CE / ISO Product Description XTM-TDK series is a new type rapid lower pressing hydraulic press mahcine. The machine is characterized by sensitive action, safe and reliably operation. Really good pressing performance.

Operated by double-button switch.

Selector switch modes of operation: jog (setup) and run (cycle).

Flexibly adjustable pressure and stroke.

Machine dwell time and stroke could be set specially as per processing requirements.

Idea of doubled SLC(Security Light Curtain) makes it safe of operation.

Emergencey switches for safety stop;Protective fence and the safety interlock can beadded

to upgrade the secure.

Oil seals adopts ring-oriented technology, good performance of oil anti-leakage.

All pipes, flange and joint with vibrations proof and leakage proof design and setting .

Highlight of TDK

TDK series can be provided with accessory for extension of upper and lower automatic ejection function, which is widely used in machinery, electronics and other fields.System impact, cooling and

safety protection device have been taken into full consideration in the design of hydraulic system.

Technical Parameter

Scope of Application 1. TDK series rapid press machine is designed for pressing precise watchcase, watchband, dishware, spectacle frame, jewelry, medal, picture frame, circuit board and other products.

2. TDK series hydraulic press is especially suitable for embossing, laminating and other industries.

3. TDK series pressing machine is also applicable for other finished products, which are pressed

through mould such as hard alloy product and grinding wheel products etc.

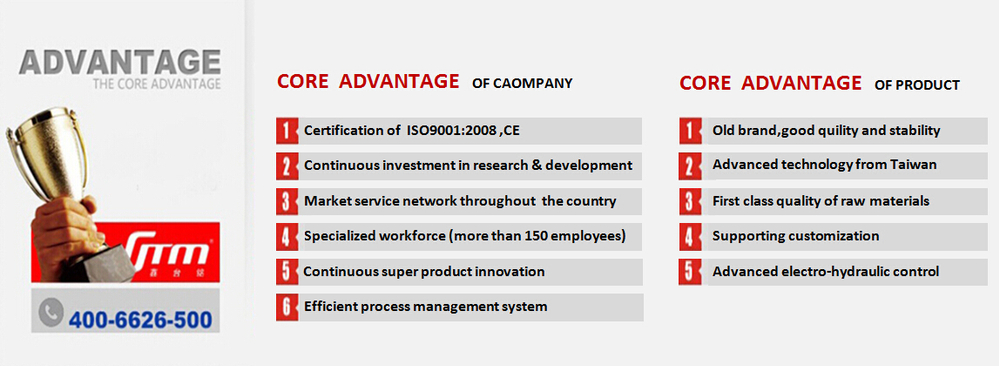

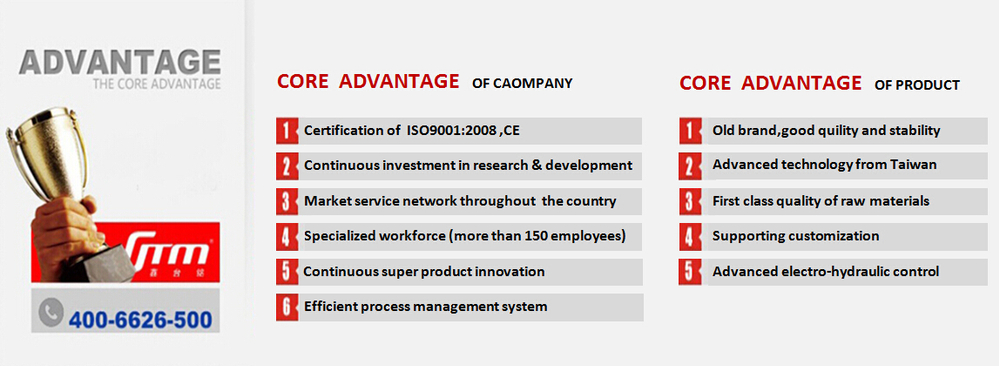

X.T.M Advantage Shenzhen Xintaiming Machinery Equipment Co.,Ltd

Shenzhen Xintaiming Machinery Equipment Co., Ltd is specialized in the designing and making all

kinds of hydraulic and pneumatic presses. 1) CNC Servo press series 2) CNC hydraulic machines 3) MD/IML 3D punching machine 4) IMD/IML hot press molding machine 5) High speed punching machine 6) Hydraulic stamping/embossing/cutting /drawing press machine and so on Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on

more than 30 countries and regions.

Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).

First class quality of raw materials .

Specialized workforce (more than 150 employees),

Wide market service network throughout the country

7500sq meter manufacturing facility ,moe than 150 full time employees , X.T.M is fully capable of handling the growing demand worldwide ,and offering excellent technology, solid qualit at highly competitive prices.

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron

etc. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and

electrical parts performane. Meanwhile, there will be video giving to you (FAT video). 3. Any error happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

(please go to the following websites to watch our Involvement Videos about XTM Series Press Machine ,have a surprise!) https://www.tudou.com/programs/view/irSJOA0jcuw/ XTM-105H Series membrane cutting https://www.tudou.com/programs/view/v_HWbn_AT8I/ XTM-106 Series Die casting parts TRIMMING MACHINE https://www.tudou.com/programs/view/uutePmlLzpU/ XTM-109 Series IMD Machine https://www.tudou.com/programs/view/_dYscK9jDe0/ XTM-106K Series Wood Die Cutting Machine

Q1: Are you a factory or trading company? A: We are a factory. Q2: Where is your factory located? How can I visit there? A: Our factory is located in E Gong Ling West RD. 6-12, Liu Lian Community, Pingdi Town, Longgang District, Shenzhen China. You can fly to Shenzhen Airport and then take the metro or city bus to our factory.Warmly welcome to visit us! Q3:How does your factory do about quality control? A: We have been CE/ISO certificated and have a complete quality controlling system. We test all the accesories to ensure the quality, and adopt the advanced assembly technology during production and debug before shipping. Q4: What's the payment terms? A:T/T, 40% deposits; 60% balance before deliverying is available

Strong research and development ability, powerful marketing ability, commitment, expertise and dedication. When it comes to hydraulic / pneumatic based press machines, Please feel no hesitation to contract with X.T.M.

Capacity:100 Ton to 1000 Ton;

Easily Adjust The Pressure Via Pressure Regulater;

H frame Up Stroke Type Hydraulic Press for Metal Manufacturing With CE / ISO Product Description XTM-TDK series is a new type rapid lower pressing hydraulic press mahcine. The machine is characterized by sensitive action, safe and reliably operation. Really good pressing performance.

Operated by double-button switch.

Selector switch modes of operation: jog (setup) and run (cycle).

Flexibly adjustable pressure and stroke.

Machine dwell time and stroke could be set specially as per processing requirements.

Idea of doubled SLC(Security Light Curtain) makes it safe of operation.

Emergencey switches for safety stop;Protective fence and the safety interlock can beadded

to upgrade the secure.

Oil seals adopts ring-oriented technology, good performance of oil anti-leakage.

All pipes, flange and joint with vibrations proof and leakage proof design and setting .

Highlight of TDK

TDK series can be provided with accessory for extension of upper and lower automatic ejection function, which is widely used in machinery, electronics and other fields.System impact, cooling and

safety protection device have been taken into full consideration in the design of hydraulic system.

Technical Parameter

| Model | Unit | TDK-100 | TDK-200 | TDK-300 | TDK-500 | TDK-600 | TDK-1000 | |

| Cylinder nominal force | KN | 1000 | 2000 | 3000 | 5000 | 6000 | 10000 | |

| Max. hydraulic pressure | MPa | 21 | 20 | 21 | 25 | 25 | 24 | |

| Max. stroke of ram | mm | 200 | 200 | 200 | 200 | 200 | 250 | |

|

shut height

| Max. |

mm | 400 | 420 | 420 | 450 | 450 | 450 |

| Min. | 200 | 220 | 220 | 250 | 250 | 250 | ||

|

dimension of table | L-R |

mm | 430 | 530 | 590 | 740 | 810 | 920 |

| F-B | 450 | 530 | 600 | 740 | 810 | 920 | ||

|

Speed of slide | moving up |

mm/s | 115 | 115 | 115 | 100 | 100 | 100 |

| return | 100 | 100 | 100 | 120 | 120 | 120 | ||

Overall size | L-R | mm | 1310 | 1450 | 1530 | 1885 | 2030 | 2330 |

| F-B | 1190 | 1190 | 1190 | 1490 | 1490 | 1490 | ||

| H | 1650 | 1660 | 1740 | 2130 | 2420 | 2660 | ||

Power of motor | KW | 5.5 | 7.5 | 7.5 | 11 | 15 | 18.5 | |

| Approx. total weight | T | 2.5 | 3.6 | 4.5 | 9.2 | 12 | 17.2 | |

2. TDK series hydraulic press is especially suitable for embossing, laminating and other industries.

3. TDK series pressing machine is also applicable for other finished products, which are pressed

through mould such as hard alloy product and grinding wheel products etc.

X.T.M Advantage Shenzhen Xintaiming Machinery Equipment Co.,Ltd

| About Us |

kinds of hydraulic and pneumatic presses. 1) CNC Servo press series 2) CNC hydraulic machines 3) MD/IML 3D punching machine 4) IMD/IML hot press molding machine 5) High speed punching machine 6) Hydraulic stamping/embossing/cutting /drawing press machine and so on Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on

more than 30 countries and regions.

| Why Choose Us |

Key aspects of the X.T.M success are: Continuous investment in research & development (more than 7% of profits).

First class quality of raw materials .

Specialized workforce (more than 150 employees),

Wide market service network throughout the country

7500sq meter manufacturing facility ,moe than 150 full time employees , X.T.M is fully capable of handling the growing demand worldwide ,and offering excellent technology, solid qualit at highly competitive prices.

| Our Serive |

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron

etc. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and

electrical parts performane. Meanwhile, there will be video giving to you (FAT video). 3. Any error happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

| Other Products |

| FAQ |

Strong research and development ability, powerful marketing ability, commitment, expertise and dedication. When it comes to hydraulic / pneumatic based press machines, Please feel no hesitation to contract with X.T.M.

Related Keywords

Related Keywords

You May Also Like

You May Also Like