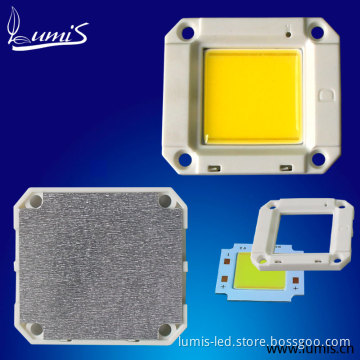

2700k Warm White SMD LED 0.2W Epistar Chip for Tube Light

- Payment Type:

- T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen, Guangdong |

|---|---|

| Payment Type: | T/T, Western Union |

Product Description

Product Description

Description:

. This White Colored surface-mount LED

. Size in standard package: 3.0x1.4x0.52mm

. It has a substrate made up of a molded epoxy compound reflector sitting on top of a lead frame.

. The EMC package design is ensured with high quality component materials that allow these products to perform with high reliability.

Features and Benefits:

. Thermally Enhanced EMC Package Design

. Mid Power to High Power, up to 0.4W

. Max. Driving Current 120mA

. Compact Package Size

. High Color Quality with CRI Min. 80

. Pb-free Reflow Soldering Application

Key Applications:

. Retrofits(replacement)

. General lighting

. Indoor & Outdoor sign board back light

. Architectural / Decorative lighting

Caution:

1.Reflow soldering is recommended not to be done more than two times. In the case of more than 24 hours passed soldering after first, LEDs will be damaged.

2. Repairs should not be done after the LEDs have been soldered. When repair is unavoidable, suitable tools must be used.

3. Die slug is to be soldered.

4. When soldering, do not put stress on the LEDs during heating.

5. After soldering, do not warp the circuit board.

Notes on LumiS EMC Series soldering:

1.Recommend to use reflow machine.

2.Recommend to use heating plate soldering.

3.Manual soldering is not recommended.

Notes on reflow process:

1.To confirm whether the actual temperature curve in the reflow soldering conditions comply with recommended conditions. LEDs are guaranteed for one time reflow.

2.During reflow process do not apply force on LED active area.

3.After reflow process, PCB board should be cooled down before packing or storage.

. This White Colored surface-mount LED

. Size in standard package: 3.0x1.4x0.52mm

. It has a substrate made up of a molded epoxy compound reflector sitting on top of a lead frame.

. The EMC package design is ensured with high quality component materials that allow these products to perform with high reliability.

Features and Benefits:

. Thermally Enhanced EMC Package Design

. Mid Power to High Power, up to 0.4W

. Max. Driving Current 120mA

. Compact Package Size

. High Color Quality with CRI Min. 80

. Pb-free Reflow Soldering Application

Key Applications:

. Retrofits(replacement)

. General lighting

. Indoor & Outdoor sign board back light

. Architectural / Decorative lighting

Caution:

1.Reflow soldering is recommended not to be done more than two times. In the case of more than 24 hours passed soldering after first, LEDs will be damaged.

2. Repairs should not be done after the LEDs have been soldered. When repair is unavoidable, suitable tools must be used.

3. Die slug is to be soldered.

4. When soldering, do not put stress on the LEDs during heating.

5. After soldering, do not warp the circuit board.

Notes on LumiS EMC Series soldering:

1.Recommend to use reflow machine.

2.Recommend to use heating plate soldering.

3.Manual soldering is not recommended.

Notes on reflow process:

1.To confirm whether the actual temperature curve in the reflow soldering conditions comply with recommended conditions. LEDs are guaranteed for one time reflow.

2.During reflow process do not apply force on LED active area.

3.After reflow process, PCB board should be cooled down before packing or storage.

Related Keywords

Related Keywords

You May Also Like

You May Also Like