0.2W 2835 SMD LED with Epistar Chip

- Payment Type:

- T/T

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Payment Type: | T/T |

Description:

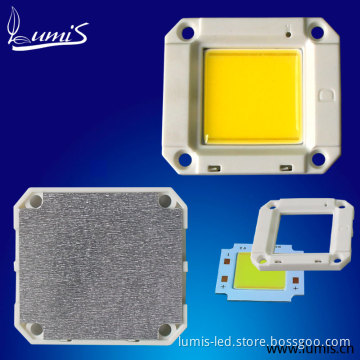

. This White Colored surface-mount LED

.Size in Standard Package: 2.8x3.5x0.75mm

. It has a substrate made up of a molded

. The PCT package design is ensured with high quality component materials that allow these products to perform with high reliability.

Features and Benefits:

. Wide Viewing Angle: 140°

. Mid Power to High Power, up to 0.24W

. Max. Driving Current 80mA

. Low Thermal Resistance:18ºC/W

. High Color Quality with CRI Min. 80

. Pb-free Reflow Soldering Application

Size:  Key Applications:

Key Applications:

. Retrofits(replacement)

. General lighting

. Indoor & Outdoor sign board back light

. Architectural / Decorative lighting

Soldering Pad:  Caution:

Caution:

Notes on LumiS PCT Series soldering:

Notes on reflow process:

Parameters:

Related Keywords