High Quality Injection Bucket Mold with Competitive Price

- Payment Type:

- L/C, T/T, Paypal, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen, China |

|---|---|

| Payment Type: | L/C, T/T, Paypal, Western Union |

Product Description

Product Description

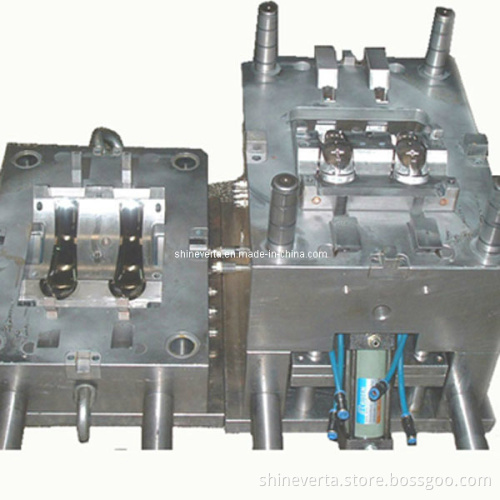

1. The series Bucket mould we have made

Shenzhen shineverta Mould Plastic & electron Co., Ltd. Is specialize in daily product moulds, fitting moulds, home appliance moulds, motorcycle moulds, automobile pats moulds, preform mould, cap mould and so on. For the detailed of the company information, please view our ''company profile'' carefully. You will get a completed view of our company.

2. Detailed description of the Bucket Mould:

Basic mould information:

Mould Base LKM/HASCO

Runner Type Hot/cold

No. Of Cavity Single/Multi

Mould Material 2738, 2316, S136, 718, P20, 45# etc.

Product Material PP, PC, PS, PE, PU, PVC, ABS, PMMA ect

Mould LIfe 1000000shots

Surface finish Mirror Polish

Mould Package Wooden case

Delivery Time 45 days

3. Bucket Mould Quality Control

For the Q/C of mould, there are 3 steps:

A). Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

B). Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- Each part of mould's size checking after machining according to 2D drawing

- mould testing(check mould running condition)

C). Check with customer's requirement again before mould shipping.

4. Bucket Mould Pack and Shipping

Anti-rust oil is painted first, then Plastic film, and finally Wooden Case.

Sent together with the mould:

A) Mould manual instruction

B) engineering drawing in flash disk

C) one more set of mould spare parts: Heater, ejector pin, bush, water nozzle, water pipe, hanging ring.

5. Bucket Mould Maintenance

A) When the mould is vacant, spray the anti-rust oil

B) To clean the gate and cooling system regularly

C) Avoid to use recycled material if the mould is suitable for virgin material only

6. After-Sale Service

A) If you are located in India, you can contact our Indian maintenance shop in Delhi.

B) Engineering and one interpreter can be sent to customer's factory for first running.

C) one-year after-sale technique support

Shenzhen shineverta Mould Plastic & electron Co., Ltd. Is specialize in daily product moulds, fitting moulds, home appliance moulds, motorcycle moulds, automobile pats moulds, preform mould, cap mould and so on. For the detailed of the company information, please view our ''company profile'' carefully. You will get a completed view of our company.

2. Detailed description of the Bucket Mould:

Basic mould information:

Mould Base LKM/HASCO

Runner Type Hot/cold

No. Of Cavity Single/Multi

Mould Material 2738, 2316, S136, 718, P20, 45# etc.

Product Material PP, PC, PS, PE, PU, PVC, ABS, PMMA ect

Mould LIfe 1000000shots

Surface finish Mirror Polish

Mould Package Wooden case

Delivery Time 45 days

3. Bucket Mould Quality Control

For the Q/C of mould, there are 3 steps:

A). Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

B). Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- Each part of mould's size checking after machining according to 2D drawing

- mould testing(check mould running condition)

C). Check with customer's requirement again before mould shipping.

4. Bucket Mould Pack and Shipping

Anti-rust oil is painted first, then Plastic film, and finally Wooden Case.

Sent together with the mould:

A) Mould manual instruction

B) engineering drawing in flash disk

C) one more set of mould spare parts: Heater, ejector pin, bush, water nozzle, water pipe, hanging ring.

5. Bucket Mould Maintenance

A) When the mould is vacant, spray the anti-rust oil

B) To clean the gate and cooling system regularly

C) Avoid to use recycled material if the mould is suitable for virgin material only

6. After-Sale Service

A) If you are located in India, you can contact our Indian maintenance shop in Delhi.

B) Engineering and one interpreter can be sent to customer's factory for first running.

C) one-year after-sale technique support

Related Keywords

Related Keywords

You May Also Like

You May Also Like