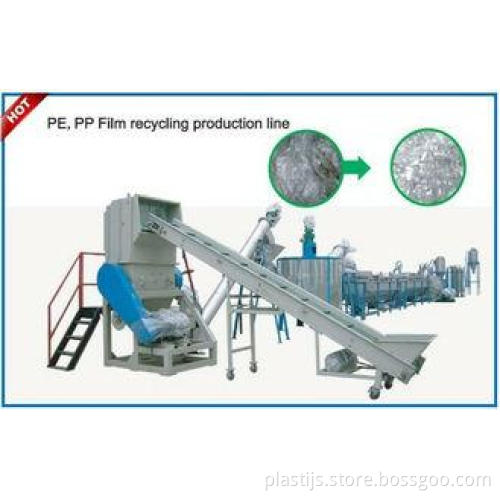

Waste Plastic PE PP Film Washing Line Recycling Machinery 3

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu ,China |

|---|

Waste Plastic PE PP Film Washing Line Recycling Machinery 380V 50HZ

Quick detail:

|

Application |

PP PE plastic bags film recycling machines |

|

Voltage |

380V 50HZ |

|

Power |

45KW-110KW |

|

Dimension(L*W*H) |

35*6*8M |

|

Weight |

8-10TON |

|

Material Processed |

plastic bag film recycling |

Description:

The whole production equipment is researched, design and manufactured by our company, integration

of Europe technology, it has features as high efficiency, working stable, large capacity etc.

Working flow the Waste PE,PP film/bags recycling (crushing, washing, and drying) machine line:

Belt conveyor→Crusher (with water) → screw conveyor→Heating washer→drainage screw→Screw

conveyor→Cooling floating washer→screw conveyor→high speed friction machine→screw conveyor→

Horizontal dewatering machine→drying system→storage hopper→control cabinet

Specification:

|

Capacity |

300kg/h |

500kg/h |

800kg/h |

|

Item |

Qty:(Set) |

Qty:(Set) |

Qty:(Set) |

|

Belt conveyor |

1 |

1 |

1 |

|

Wet Crusher |

1 |

1 |

1 |

|

Screw feeder |

1 |

1 |

1 |

|

Hot washer |

---- |

1 |

1 |

|

Screw feeder |

---- |

1 |

1 |

|

High speed friction washer |

1 |

1 |

1 |

|

Floating washer |

1 |

1 |

2 |

|

Dewatering machine |

1 |

1 |

1 |

|

Pipeline dryer |

1 |

1 |

1 |

|

Storage silo |

1 |

1 |

1 |

Competitive advantage:

Final products has good quality. When processPE,PP film(bags), final products humidity below 5%,

impurities150ppm. The whole line capacity between 300kg/h-2000kg/hour

Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service

lift time World famous brand components applied on the production line- NSK bearing, Siemens contactor,

Omron temperature, FUJI invertor, Siemens PLC controletc.

The whole production line with CE certification, ISO9001 certification;