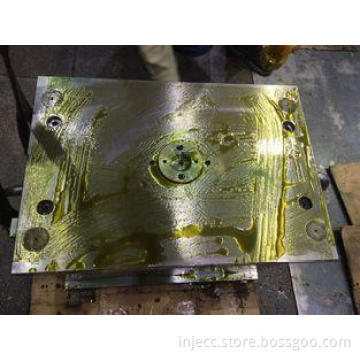

Plastic Injection Mould Tooling Factory For Plastic Parts

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong China(Mainland) |

|---|

Plastic Injection Mould and tooling factory Plastic Injection Mould

Specifications

PLASTIC MOULD

1.Competitive price.

2.Continuance service and support.

3.Quality,reliability and long product life.

Shenzhen Yonghe Tai Technology Co.,LTD is a professional in making mold and plastic products, If you need mold or products, we can help you to do this, but first please send us more and more information about the mould what you have. Like sample photo, sample size, what's the sample material and what kind of steel you want to make the mould, When we get this information, we can send the mould quote andTechnology analysis.

Our Factory Advantages

1. We are one_stop manufacturer of plastic mold and finished plastic products. Specialized in mold design, making plastic mold, injection process,spraying and silk printing.one-stop services for more than 9 years.

2. We can make molds and plastic products according to your drawings or samples.

3. Our die include: auto parts, household appliances, medical equipment, House application products, electronic and electrical appliances, handicrafts and engineering construction etc...

4. Injection products material character:soft plastic,hard plastic,transparent,ect.

5. Common used plastic material:ABS,PC ,TPR,TPU,PMMA,POM,PA,PP,BPT etc.

Plastic Injection Mould Tooling Factory For Plastic Parts

TECHNICAL SPECIFICATION

|

Name |

Description |

|

mold material |

45#, P20, S136,3Cr13,2316 etc. |

|

mold base |

LKM, HASCO etc |

|

Cavity |

Single/multi |

|

Runner |

Hot/Cold |

|

Design software |

PROE, CAD, CAM,CAE etc. |

|

Plastic material |

PP, PE, PET etc. |

|

Mould life |

500,000-3,000,000 shots |

|

Delivery time |

30-50days |

|

Specification |

Depends on customer's requirements. |

Custom Your Own Mould

Mould Trade Process :

|

1.R&D |

We support customer R&D. Make the files or improve the design if you needed. |

|

↓ |

|

|

2.Negotiation |

the quality, price, material, delivery time, payment item, ect. |

|

↓ |

|

|

3.Place an order |

according your own design or you chooses our design. |

|

↓ |

|

|

4. Mould |

According customers request to build the preform mold . Before make the preform preform mold , |

|

↓ |

|

|

5. Sample shoot |

If the first sample come out is not satisfied customer, we modify the mould and until meet customers |

|

↓ |

|

|

6.Products in store |

If your quantity is beyond our storage, we will provide lead time to you. |

|

↓ |

|

|

7. Delivery |

Delivery goods by sea or by air, according customers requiremen |

Packaging & Delivery

Packaging Detail:Wooden box for moulds;Exports standard carton for products.

Delivery Detail: 28-35days