Home Appliance Mould Plastic Injection Mould For iPad Case

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong China(Mainland) |

|---|

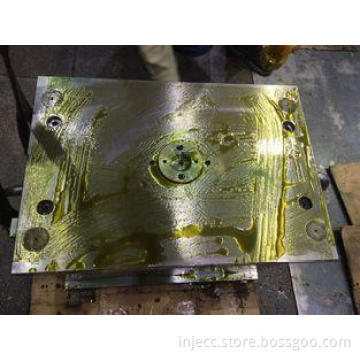

Plastic Injection Mould For IPAD Case Case For IPAD 2 3 4 Ipad Case Mold

Specifications

plastic tool case mold

1. Efficient team

2. Delivery in time

3. ISO9001:2008

4. OEM/ODM service

Shenzhen Yonghe Tai Technology Co.,LTD is a professional in making mold and plastic products, If you need mold or products, we can help you to do this, but first please send us more and more information about the mould what you have. Like sample photo, sample size, what's the sample material and what kind of steel you want to make the mould, When we get this information, we can send the mould quote andTechnology analysis.

Our Factory Advantages

1. We are one_stop manufacturer of plastic mold and finished plastic products. Specialized in mold design, making plastic mold, injection process,spraying and silk printing.one-stop services for more than 9 years.

2. We can make molds and plastic products according to your drawings or samples.

3. Our die include: auto parts, household appliances, medical equipment, House application products, electronic and electrical appliances, handicrafts and engineering construction etc...

4. Injection products material character:soft plastic,hard plastic,transparent,ect.

5. Common used plastic material:ABS,PC ,TPR,TPU,PMMA,POM,PA,PP,BPT etc.

Home Appliance Mould Plastic Injection Mould For iPad Case Mold

TECHNICAL SPECIFICATIONS

| Mould standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard, etc |

| Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ), etc |

| Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13, etc |

| Hardness of steel | 46~56HRC |

|

Material for Slider , Lifter and all sub insert use |

1.2767 HRC |

| Cavity | Single-cavity ,Multi-cavity |

| A surface request: | EDM & High Polish |

| Gate | Cold runner ,Yudo/DME/HASCO/Synventive Hot runner |

| Maximum mould size | 20000*1500 *1200mm |

| Mould life time | 500000~+1,000,000 shots |

| Quality | ISO9001-2008, |

| Product material | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

| Lead time | 2~7 Weeks |

| Package | Wooden/Plywood case for tool ,PE bags add export carton for parts |

| Payment terms | T/T, L/C |

| Export country | Japan, Europe, USA ,Mexico, brazil, Australia ,Middle-east ,Asia etc |

| Value-added service | Polish, texture, painting, screen printing, turnkey project |

Mould Trade Process :

| 1.Quote | According to sample,drawing and specific requirement. | ||||||||

| ↓ | |||||||||

| 2.Discussion | Mold material,cavity number,price,runner,payment,etc. | ||||||||

| ↓ | |||||||||

| 3.S/C Signature | Approval for all the items. | ||||||||

| ↓ | |||||||||

| 4.Advance | Pay 50% by T/T | ||||||||

| ↓ | |||||||||

| 5.Product Design Checking | We check the product design.If some position is not perfect,or can not be done on the mould,we will send customer the report. | ||||||||

| ↓ | |||||||||

| 6.Mould Design | We make mould design on the basis of confirmed product design,and send to customer for confirmation. | ||||||||

| ↓ | |||||||||

| 7.Mold Tooling | We start to make mold after mold design confirmed. | ||||||||

| ↓ | |||||||||

| 8.Mold Processing | Send report to customer once each week. | ||||||||

| ↓ | |||||||||

| 9.Mold Testing | Send trial samples and try-out report to customer for confirmation . | ||||||||

| ↓ | |||||||||

| 10.Mold Modification | According to customer'feedback. | ||||||||

| ↓ | |||||||||

| 11.Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. | ||||||||

| ↓ | |||||||||

| 12.Delivery | Delivery by sea or air.The forwarder can be designated by your side. | ||||||||

Packaging & Delivery

Packaging Detail:Wooden box for moulds;Exports standard carton for products.

Delivery Detail: 28-35days

Products photo

Ipad can be put into the tool box!