NAK80 Tempering Forging Die Steel Pre-harden for Transparen

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|

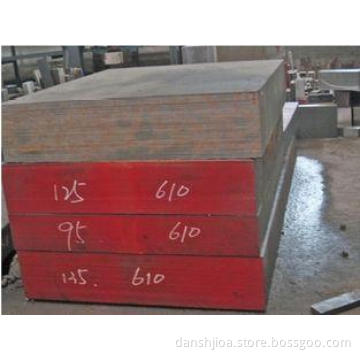

NAK80 Tempering Forging Die Steel Pre-harden for Transparent Moulds SPE1921-GR3

1. Forged condition, Pre-harden & tempering, milled surface

2. Hardness: 38~42HRC

3. Forged technology: EAF+LF+VD+ESR+Forging +Q T + Machined surface

4. Production leadtime: 7~15 days

5. Ultrasonic test standard: SPE1921-GR3, CLASS E/E

Applications:

· Used for high-grade mirror mold (Molds for transparent, e. G. Cosmetics containers, food containers and daily electrical appliances. )

· Used for the mold focusing on discharge machining surface, (Molds for such products as fruit plate, food box, computer casing, keyboards and automobile interior decorations)

Used for plastic molds under long production at high precision. (Molds for such products as electrical switches, multifunctional sockets, plugs, charger cashing and computer parts. )

Competitive Advantage:

1. Good workability and mirror polishing property, suitable for thermoset molding of general resin

2. Material is a steel smelted by using refining degassing and ESP remelting, suitable for super-mirror

molds with high polishing property requirements.

3. Stable hardness after electric spark machining, easy to repair and Polish the mold

4. Competitive price

5. Fast production leadtime

6. All the material are inspected with 3 times to meet the highly standards material supplied

Specification:

| Steel plate(mm) | Mill name | ||||

| Thickness | Width | Length | |||

| Forged condition | 120 ~ 800 | 335 ~1200 | 2500~4000 | Local mill with 6000tons fluid forged machine | |

Chemical composition:

| C | Si | Mn | Ni | Cu | Mo | Al | P&S | Cr |

| 0.1-0.15 | 0.15-1.0 | 1.0-2.0 | 2.50-3.50 | 0.70-1.50 | 0.10-0.40 | 0.7~1.1 | ≤0.03 | ≤0.05 |

|

Compared grades(based on usage) |

| GB | JIS |

| 1Ni3Mn2CuAlMo | NAK80 |