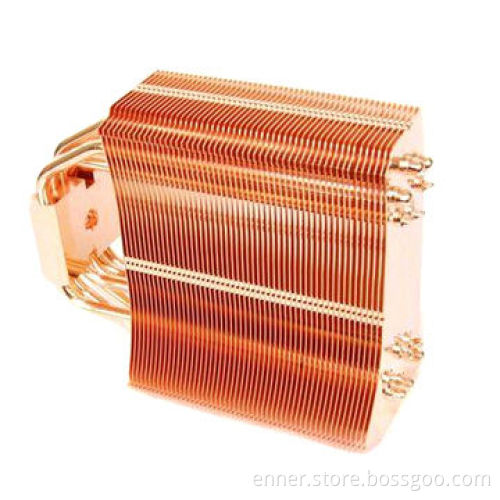

Aluminum heatsink for CPU cooler

- Payment Type:

- Telegraphic Transfer (TT, T/T)

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | Telegraphic Transfer (TT,T/T) |

|---|

Product Description

Product Description

- High heatsink surface: the surface of the heatsink where the thermal transfer takes place

- Heatsinks should be designed to have a large surface, this goal can be reached by using a large amount of fine fins or by increasing the size of the heatsink itself

- Good aerodynamics: heatsinks must be designed in a way that air can easily and quickly float through the cooler and reach all cooling fins

- Especially heatsinks having a very large amount of fine fins, with small distances between the fins may not allow good air flow

- Compromises between high surface (many fins with small gaps between them) and good aerodynamics

- Also depends on the fan the heatsink is used

- A powerful fan can force air even through a heatsink with lots of fine fins with only small gaps for air flow, whereas on a passive heatsink, there should be fewer cooling fins with more space between them

- Simply adding a fan to a large heatsink designed for fanless usage doesn't necessarily result in a good cooler

- Good thermal transfer within the heatsink

- Large cooling fins are pointless if the heat can't reach them, so the heatsink must be designed to allow good thermal transfer from the heat source to the fins

- Thicker fins have better thermal conductivity, compromises between high surface (many thin fins) and good thermal transfer (thicker fins) must be found

- Materials used has a major influence on thermal transfer within the heatsink

- Sometimes the heat pipes are used to lead the heat from the heat source to the parts of the fins that are further away from the heat source

- Perfect flatness of the contact area

- The part of the heatsink that is in contact with the heat source must be perfectly flat

- A flat contact area allows you to use a thinner layer of thermal compound, which will reduce the thermal resistance between heatsink and heat source

- Good mounting method, for good thermal transfer, the pressure between heatsink and heat source must be high

- Heatsink clips must be designed to provide a strong pressure, while still being reasonably easy to install

- Heatsink mountings with screws/springs are often better than regular clips

- Thermo-conductive glue or sticky tape should only be used in situations where mounting with clips or screws aren't possible

Related Keywords

Related Keywords

You May Also Like

You May Also Like